- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

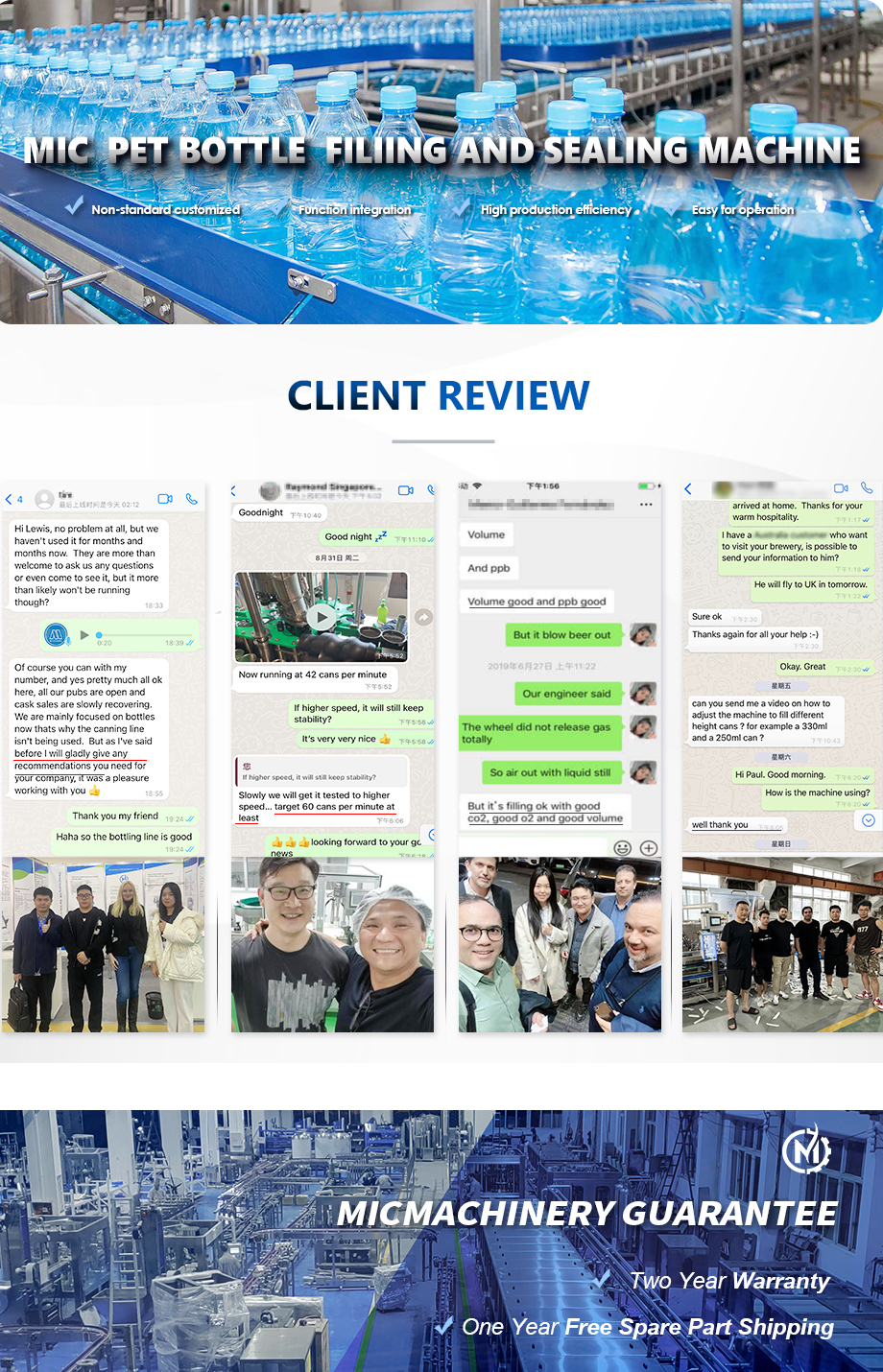

- Customer reviews: click on

MIC14-12-5 beverage bottling equipment is a kind of professional filling machine for juice, mineral water, pure water which applies to PET bottle. It is made of high quality SUS304 stainless steel. Main components are processed precisely by CNC machine tool. The machine adopts advanced photo electricity to detect running status. No bottle no filling. It realize man-machine conversation because of applying touch screen for operation

1) Bottle is entered by air conveyor, the speed of bottle entering is fast and bottle shape isn’t changed because of adopting hanging clamping bottleneck way

2) Adopting clamping bottleneck way to wash bottle mouth and avoid touching screw mouth, adopting clamping bottleneck way in the whole conveying process. When bottle type changes, you need to change the board related with bottle diameter

3) Filling adopts cylinder feeding structure, filling valve adopts high filling speed and mass flow rate valve which control liquids level accurately and without loss.

4) Screw capper adopts French advanced technology which cans screw cap promptly when clamping bottle.

5) The PLC and transducer are chosen from international famous brand, such as OMRON, MITSUBISHI.

The bottle is turned upside down and centered above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again.

Rotary wheel fully made of stainless steel SUS 304. Filling valves are made of SUS316L. Filling valves are reasonably structured with accurate filling. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. The capper is equipped with inlet bottle detection switch.

1) Bottle is entered by air conveyor, the speed of bottle entering is fast and bottle shape isn’t changed because of adopting hanging clamping bottleneck way

2) Adopting clamping bottleneck way to wash bottle mouth and avoid touching screw mouth, adopting clamping bottleneck way in the whole conveying process. When bottle type changes, you need to change the board related with bottle diameter

3) Filling adopts cylinder feeding structure, filling valve adopts high filling speed and mass flow rate valve which control liquids level accurately and without loss.

4) Screw capper adopts French advanced technology which cans screw cap promptly when clamping bottle.

5) The PLC and transducer are chosen from international famous brand, such as OMRON, MITSUBISHI.

Beverage bottling equipment encompasses a range of specialized machinery designed to efficiently package various types of beverages. From carbonated soft drinks and juices to still water and energy drinks, this equipment plays a crucial role in the production line. Beverage bottling equipment offers precise control over critical processes such as filling, capping, labeling, and packaging, ensuring consistent quality, hygiene, and efficiency throughout the production cycle.

Introducing the MIC14-12-5 Beverage Bottling Equipment

At Micmachinery, we are proud to unveil our cutting-edge MIC14-12-5 Beverage Bottling Equipment, designed for efficient and reliable bottling operations with a speed range of 3000 to 5000 bottles per hour (BPH). This state-of-the-art beverage bottle filling machine is engineered to meet the diverse needs of the beverage industry, offering exceptional performance and versatility.

The MIC14-12-5 beverage bottling machine is perfect for a variety of beverages, including carbonated drinks and juices, ensuring you can cater to a wide market. Its adaptable filling system allows for easy adjustments to accommodate different bottle sizes and shapes, providing flexibility for your production line.

Key Features

1. High Efficiency

With its impressive speed capabilities, this beverage bottling equipment significantly enhances productivity, reducing downtime and ensuring a steady flow in your production process.

2. Accurate Filling

Our advanced filling technology guarantees precise fill levels, ensuring product consistency and minimizing waste. This accuracy translates to higher quality and customer satisfaction.

3. User-Friendly Interface

Designed with operators in mind, the control panel is intuitive and easy to use. This facilitates quick training for staff, allowing for smooth operation and minimal disruption.

4. Durable Construction

Built from high-quality materials, the beverage bottle filling machine is designed for longevity and reliability, minimizing maintenance needs and maximizing uptime.

5. Safety Features

Safety is paramount at Micmachinery. The MIC12-12-5 includes multiple safety mechanisms that protect operators and ensure compliance with industry standards, creating a safe working environment.

Conclusion

Choosing Micmachinery means investing in quality and reliability. Our MIC14-12-5 Beverage Bottling Equipment is more than just a beverage bottling machine; it’s a comprehensive solution designed to elevate your production capabilities. With our commitment to innovation and customer satisfaction, we are here to support your business’s growth and success. Let us help you achieve your bottling goals with our advanced technology and expertise.

At Micmachinery, we are proud to unveil our cutting-edge MIC14-12-5 Beverage Bottling Equipment, designed for efficient and reliable bottling operations with a speed range of 3000 to 5000 bottles per hour (BPH). This state-of-the-art beverage bottle filling machine is engineered to meet the diverse needs of the beverage industry, offering exceptional performance and versatility.

The MIC14-12-5 beverage bottling machine is perfect for a variety of beverages, including carbonated drinks and juices, ensuring you can cater to a wide market. Its adaptable filling system allows for easy adjustments to accommodate different bottle sizes and shapes, providing flexibility for your production line.

Key Features

1. High Efficiency

With its impressive speed capabilities, this beverage bottling equipment significantly enhances productivity, reducing downtime and ensuring a steady flow in your production process.

2. Accurate Filling

Our advanced filling technology guarantees precise fill levels, ensuring product consistency and minimizing waste. This accuracy translates to higher quality and customer satisfaction.

3. User-Friendly Interface

Designed with operators in mind, the control panel is intuitive and easy to use. This facilitates quick training for staff, allowing for smooth operation and minimal disruption.

4. Durable Construction

Built from high-quality materials, the beverage bottle filling machine is designed for longevity and reliability, minimizing maintenance needs and maximizing uptime.

5. Safety Features

Safety is paramount at Micmachinery. The MIC12-12-5 includes multiple safety mechanisms that protect operators and ensure compliance with industry standards, creating a safe working environment.

Conclusion

Choosing Micmachinery means investing in quality and reliability. Our MIC14-12-5 Beverage Bottling Equipment is more than just a beverage bottling machine; it’s a comprehensive solution designed to elevate your production capabilities. With our commitment to innovation and customer satisfaction, we are here to support your business’s growth and success. Let us help you achieve your bottling goals with our advanced technology and expertise.

Washing Part

Washing part is mainly composed of washing pump, bottle clamps, water distributor, up turn-plate, guide rail, protection cover, spraying device, defrosting tray, rinse water take and rinse water refluxing tank.The bottle is turned upside down and centered above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again.

Filling Part

Filling part is mainly composed of filling barrel, filling valve (low temperature and isobar filling), filling pump, bottle hanging device / bottle pedestals, guide rail, elevating device, liquid indicator, pressure gauge, pressure regulator, etc.Rotary wheel fully made of stainless steel SUS 304. Filling valves are made of SUS316L. Filling valves are reasonably structured with accurate filling. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Capping Part

Capping part is mainly composed of capping heads, cap loader (separated), cap unscrambler, cap drop rail, pressure regular, cylinder and also we need an air compressor as the auxiliary external equipment.Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. The capper is equipped with inlet bottle detection switch.

| Model | MIC 12-12-5 |

|---|---|

| Working section | Washing 12, filling 12, capping 5 |

| Productivity | 3000-5000BPH(Base on 500ml/bottle) |

| Air pressure | 0.4MPa |

| Air consume | 0.15m3/min |

| Washing water pressure | 0.2MPa |

| Washing water consume | Less than 1T/hour |

| Main motor power | 2.2kW |

| Total power | 5KW |

| Overall size | 2250*1650*2200mm |

| Total weight | 3500kg |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |

Water Factor, Tirana Albania, 2012

Beer Canning Factory, Wales UK, 2017,03

Products

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

Product Catalog

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment