- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Manual Beer Can Filling Machine is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius)

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the counter pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

Looking for a compact and efficient solution for your small-scale beer canning needs? Micmachinery offers a small beer filling machine that can fill up to 8 cans per minute, making it perfect for small craft breweries or homebrewers.

Our small beer filling machine is designed with simplicity and ease-of-use in mind, making it ideal for those just starting out in canning beer. It features a manual can seamer, automatic filling controls, and a compact footprint, making it easy to fit into any brewery setup.

With our small beer filling machine, you can quickly and easily fill your beer cans with precision and consistency. Plus, its low cost and minimal maintenance requirements make it an affordable and practical option for small-scale beer canning operations.

At Micmachinery, we're committed to providing high-quality beer filling machines that meet the needs of breweries and homebrewers of all sizes. Contact us today to learn more about how our equipment can benefit your brewery and take your beer canning to the next level.

Why Choose the MIC Small Beer Filling Machine?

The MIC Small Beer Filling Machine is a powerful solution for breweries that require reliable and efficient filling capabilities. With a production speed of 8 cans per minute, it’s designed for smaller operations that prioritize control, quality, and consistency in each canning run. This beer filling machine offers a streamlined solution that allows brewers to focus on crafting the perfect product while maintaining efficiency and productivity.

Key Features of the MIC Small Beer Filling Machine

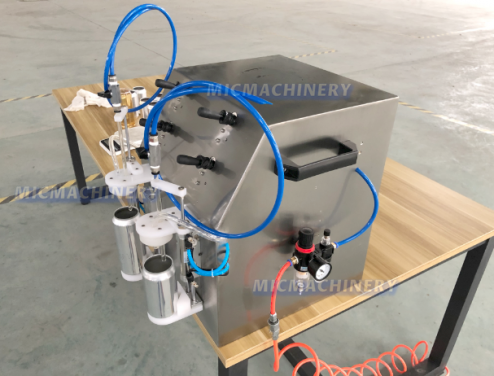

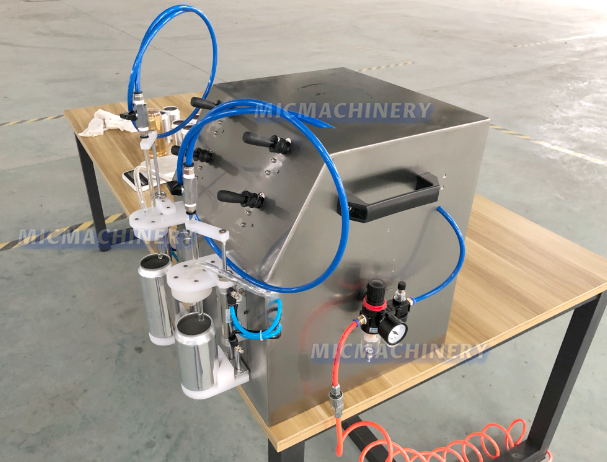

1. Compact Design for Small Spaces

The MIC Small Beer Filling Machine is built with a compact, space-saving design that allows it to fit seamlessly into smaller production setups. This small beer filling machine is ideal for craft brewers and small operations where space is at a premium, providing a professional canning solution without taking up excessive room.

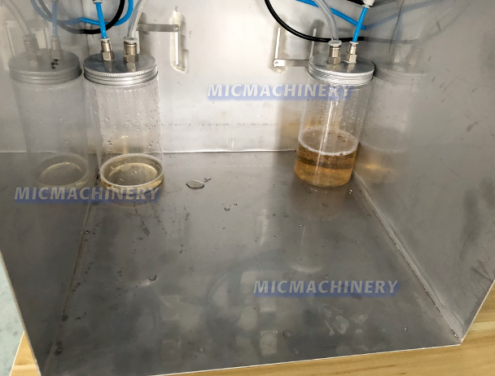

2. Precision Filling Technology

To preserve the flavor, aroma, and carbonation of each brew, this beer can filling machine utilizes advanced filling technology that ensures consistent fill levels and minimizes foaming. This level of precision protects the integrity of the product, offering an experience that meets the high standards of both brewers and their customers.

3. Stainless Steel Construction for Durability

Constructed from food-grade stainless steel, the MIC Small Beer Filling Machine is designed to withstand the rigorous demands of a brewery environment. The durable materials prevent corrosion, make cleaning easy, and ensure a hygienic canning process that meets industry standards for quality and safety.

4. Easy-to-Use Interface

This beer filling machine is designed with user-friendliness in mind. The intuitive interface allows operators to monitor and adjust the filling process with ease, minimizing setup time and reducing the need for extensive training. The straightforward controls make this machine an efficient and accessible solution, ideal for small businesses and craft brewers who need a dependable machine without complex controls.

Benefits of the MIC Small Beer Filling Machine

With its compact design, user-friendly operation, and reliable filling performance, the MIC Small Beer Filling Machine is an essential tool for breweries that want to enhance their production line. It provides small-scale producers with the flexibility to manage their canning needs in-house, allowing them to maintain greater control over their products’ quality and freshness. Additionally, this beer can filling machine can help breweries save on outsourcing costs by providing an affordable, professional-grade filling solution in a compact form.

Micmachinery: Quality Solutions for Every Brewer

At Micmachinery, we understand that every brewery has unique needs. The MIC Small Beer Filling Machine reflects our dedication to offering quality, reliability, and innovation, no matter the scale of your operation. As a trusted partner in the beverage industry, we are committed to providing solutions that support your business goals and help you achieve consistent, high-quality results.

If you’re ready to elevate your brewing operation, reach out to our team today to learn more about the MIC small beer filling machine and discover how it can enhance your production process. Let Micmachinery be your partner in taking your craft to the next level.

Control Button

Control buttons can control when the machine starts filling and can stop filling manually. It also can change the counter pressure filling valves to normal pressure filling valves.then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

Filling Head

After pressing the button, the filling head enters the inside of the cans and fills the beer into the cans. Filling heads are easy to replace and clean.

| Filling Heads | 2 Pieces |

| Production Capacity | 8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure |

0.4-0.6Mpa |

|

Can Diameter Range |

Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight |

15KG |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment