- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The sealing speed of the machine can reach 15Pcs/min, the power is only 0.55KW, and the power consumption is small.

The machine body is small in size, saving space, low in cost but high in efficiency,we can customize the most suitable machine for you according to the different needs of customers

Introduction to MIC Semi-Automatic Soft Drink Filling Machine

In the soft drink production industry, ensuring that your cans are securely sealed to preserve freshness and prevent contamination is crucial. The MIC Semi-Automatic Soft Drink Filling Machine provides a perfect solution for small to medium-scale production, offering reliable performance, ease of use, and cost-effective operation. Designed for breweries, beverage manufacturers, and soft drink producers, this machine ensures high sealing efficiency with flexibility, making it the ideal choice for those looking to scale their production processes.

What is the MIC Semi-Automatic Soft Drink Filling Machine?

The MIC Semi-Automatic Soft Drink Filling Machine is a versatile and efficient machine designed to seal soft drink cans quickly and securely. It operates semi-automatically, meaning that operators manually load the cans onto the machine, while the machine performs the sealing process automatically. This design provides flexibility and ease of operation, making it an ideal choice for businesses that require moderate sealing volumes and precision.

Key Features and Benefits

-

Versatile Sealing: The soft drink canning sealing machine is designed to seal cans of various sizes and materials, including aluminum and tin, ensuring compatibility with different beverage types. Whether you are sealing carbonated drinks, juices, or flavored waters, this machine ensures a tight and secure seal for each can.

-

High Efficiency: With a quick sealing time and minimal manual input, the Semi-Automatic Soft Drink Filling Machine boosts productivity while reducing labor costs. It is ideal for small to medium-scale production lines, offering sealing speeds that match the requirements of growing businesses.

-

Accurate Sealing: This machine ensures precise, leak-proof seals with minimal variation. It reduces the risk of seal failure, ensuring that each can is sealed to the highest standards. The sealing process is reliable, preserving the carbonation and freshness of the drink.

-

User-Friendly Operation: The semi-automatic design makes this machine easy to operate, even for those with minimal experience. Cans are loaded manually, and the sealing process is automated, offering simplicity without compromising on quality.

-

Durable Construction: Built with food-grade materials like SS304 stainless steel, the soft drink sealing machine is robust, long-lasting, and resistant to corrosion. This ensures a clean and hygienic sealing process that meets industry standards.

-

Energy Efficiency: The MIC Semi-Automatic Soft Drink Filling Machine is designed with energy-saving features that reduce power consumption while maintaining high performance. This makes it a cost-effective choice for businesses that are conscious of energy use.

Applications

The MIC Semi-Automatic Soft Drink Filling Machine is ideal for a wide range of applications within the beverage industry. It is particularly suited for soft drink manufacturers, craft beverage producers, or small breweries looking to bottle and seal their products without the need for large-scale automated machinery. This machine can seal cans for carbonated beverages, juices, and other soft drinks, providing high-quality sealing in each production cycle.

Conclusion

The MIC Semi-Automatic Soft Drink Filling Machine is the perfect solution for companies seeking an efficient, cost-effective, and reliable sealing process. Whether you’re producing small batches or increasing production volume, this machine offers exceptional sealing quality, enhanced productivity, and reduced operational costs. If you're looking for a soft drink canning sealing machine that combines flexibility with precision, this machine is the perfect addition to your production line.

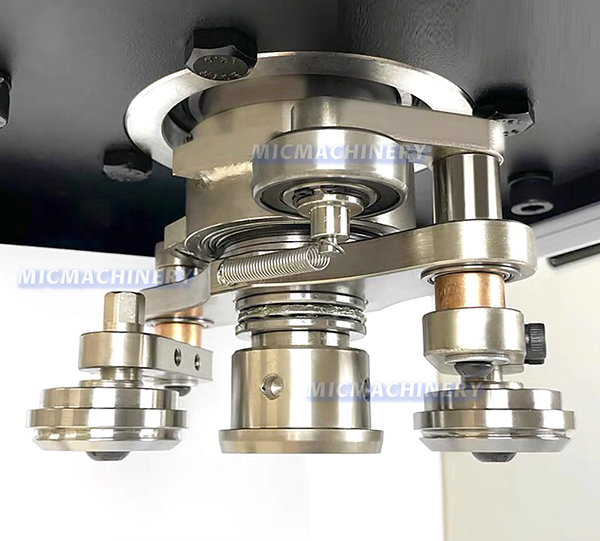

Sealing Station

The machine is suitable for sealing cans of various sizes, the liquid does not overflow during the sealing process, the tank itself does not rotate, and the sealing is closer.

Work flow of capping machine

After filling, manually put the lid on, put the can on the tray of the capping machine, open the start button, and the internal device rotates at high speed and spins the cap efficiently.

|

Weight |

52kg |

|

Voltage |

220V 50Hz |

|

Packaging Type |

CANS, Bottles |

|

Dimension |

255*455*608mm |

|

Motor power |

0.55KW |

|

Filling speed |

30 cans each minute |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment