- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The machine is suitable for sealing cans of various sizes, the liquid does not overflow during the sealing process, the tank itself does not rotate, and the sealing is closer.

The sealing speed of the machine can reach 1800Pcs/hour, the power is only 0.55KW, and the power consumption is small.

The machine body is small in size, saving space, low in cost but high in efficiency,we can customize the most suitable machine for you according to the different needs of customers

The sealing speed of the machine can reach 1800Pcs/hour, the power is only 0.55KW, and the power consumption is small.

The machine body is small in size, saving space, low in cost but high in efficiency,we can customize the most suitable machine for you according to the different needs of customers

MIC Semi Automatic Juice Can Capping Machine: A Reliable Solution for Efficient Production

At Micmachinery, we specialize in providing cutting-edge solutions for the beverage and food processing industries. The MIC Semi Automatic Juice Can Capping Machine exemplifies our commitment to innovation and reliability. Designed for small to medium production lines, this machine combines precision, durability, and ease of use, making it an excellent choice for businesses aiming to optimize their packaging processes.

Key Features of the MIC Semi Automatic Juice Can Capping Machine

1. High-Precision Capping Performance

This juice can capping machine is engineered to deliver consistent, airtight seals, ensuring product integrity and preventing leaks during transportation or storage. Its advanced capping mechanism is compatible with various can sizes, providing unmatched versatility.

2. Semi-Automatic Operation for Efficiency

Striking the perfect balance between automation and manual control, this machine enhances productivity while allowing operators to oversee the capping process closely. Its semi-automatic functionality reduces labor-intensive tasks, making it more efficient than a fully Manual juice can capping machine while remaining user-friendly.

3. Durable and Hygienic Construction

Constructed from high-quality stainless steel, the can capping machine ensures long-lasting performance and meets food-grade standards. Its robust design resists corrosion and is easy to clean, maintaining hygiene in production environments.

4. Ease of Use and Maintenance

The machine's intuitive design and straightforward operation make it accessible to operators with varying skill levels. Additionally, it requires minimal maintenance, reducing downtime and ensuring smooth production runs.

5. Compact and Space-Saving Design

Ideal for production facilities with limited space, the compact footprint of this juice can capping machine allows seamless integration into existing production lines.

Why Choose the MIC Semi Automatic Juice Can Capping Machine?

Cost-Effective Solution: Offers an economical alternative to fully automated systems while delivering reliable performance.

Versatility: Compatible with a wide range of juice cans, including different sizes and materials.

Energy Efficiency: Designed to minimize power consumption without compromising output quality.

Applications of the MIC Semi Automatic Juice Can Capping Machine

This machine is perfectly suited for juice producers, beverage companies, and small-scale manufacturers seeking a reliable and efficient Manual juice can capping machine. It is ideal for sealing fruit juices, carbonated beverages, and other liquid products, ensuring airtight capping for prolonged freshness and quality.

Micmachinery: Excellence in Beverage Processing Solutions

As a trusted name in the manufacturing of packaging equipment, Micmachinery takes pride in delivering tailored solutions to meet the unique needs of our clients. The MIC Semi Automatic Juice Can Capping Machine is a testament to our dedication to innovation and quality. Backed by robust engineering and customer-centric support, our machines are designed to help businesses achieve their production goals efficiently.

At Micmachinery, we specialize in providing cutting-edge solutions for the beverage and food processing industries. The MIC Semi Automatic Juice Can Capping Machine exemplifies our commitment to innovation and reliability. Designed for small to medium production lines, this machine combines precision, durability, and ease of use, making it an excellent choice for businesses aiming to optimize their packaging processes.

Key Features of the MIC Semi Automatic Juice Can Capping Machine

1. High-Precision Capping Performance

This juice can capping machine is engineered to deliver consistent, airtight seals, ensuring product integrity and preventing leaks during transportation or storage. Its advanced capping mechanism is compatible with various can sizes, providing unmatched versatility.

2. Semi-Automatic Operation for Efficiency

Striking the perfect balance between automation and manual control, this machine enhances productivity while allowing operators to oversee the capping process closely. Its semi-automatic functionality reduces labor-intensive tasks, making it more efficient than a fully Manual juice can capping machine while remaining user-friendly.

3. Durable and Hygienic Construction

Constructed from high-quality stainless steel, the can capping machine ensures long-lasting performance and meets food-grade standards. Its robust design resists corrosion and is easy to clean, maintaining hygiene in production environments.

4. Ease of Use and Maintenance

The machine's intuitive design and straightforward operation make it accessible to operators with varying skill levels. Additionally, it requires minimal maintenance, reducing downtime and ensuring smooth production runs.

5. Compact and Space-Saving Design

Ideal for production facilities with limited space, the compact footprint of this juice can capping machine allows seamless integration into existing production lines.

Why Choose the MIC Semi Automatic Juice Can Capping Machine?

Cost-Effective Solution: Offers an economical alternative to fully automated systems while delivering reliable performance.

Versatility: Compatible with a wide range of juice cans, including different sizes and materials.

Energy Efficiency: Designed to minimize power consumption without compromising output quality.

Applications of the MIC Semi Automatic Juice Can Capping Machine

This machine is perfectly suited for juice producers, beverage companies, and small-scale manufacturers seeking a reliable and efficient Manual juice can capping machine. It is ideal for sealing fruit juices, carbonated beverages, and other liquid products, ensuring airtight capping for prolonged freshness and quality.

Micmachinery: Excellence in Beverage Processing Solutions

As a trusted name in the manufacturing of packaging equipment, Micmachinery takes pride in delivering tailored solutions to meet the unique needs of our clients. The MIC Semi Automatic Juice Can Capping Machine is a testament to our dedication to innovation and quality. Backed by robust engineering and customer-centric support, our machines are designed to help businesses achieve their production goals efficiently.

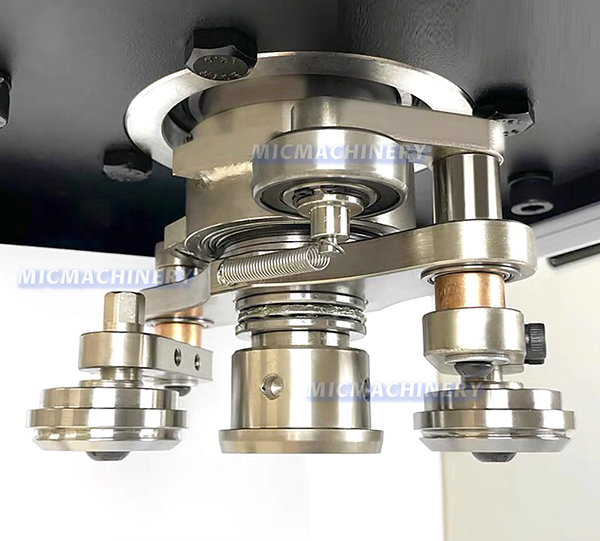

Capping Station

The machine is suitable for sealing cans of various sizes, the liquid does not overflow during the sealing process, the tank itself does not rotate, and the sealing is closer.

Work flow of capping machine

After filling, manually put the lid on, put the can on the tray of the capping machine, open the start button, and the internal device rotates at high speed and spins the cap efficiently.

|

Weight |

52kg |

|

Voltage |

220V 50Hz |

|

Packaging Type |

CANS, Bottles |

|

Dimension |

255*455*608mm |

|

Motor power |

0.55KW |

|

Filling speed |

30 cans each minute |

Products

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

Product Catalog

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment