- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

semi automatic beer glass bottle filling cappingng machine on the basis of independent development of the bottle filling, capping unit.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

At Micmachinery, we specialize in crafting advanced beverage processing equipment to meet the diverse needs of our customers. The MIC Semi Automatic Carbonated Drink Bottle Filling Capping Machine is a reliable and efficient solution for small to medium-scale production lines. Designed to fill and cap carbonated beverages such as beer, soda, and sparkling water, this machine offers exceptional performance at an affordable price.

Whether you’re seeking a semi automatic beer bottle filling machine for increased productivity or a compact manual beer bottle filling machine for flexibility, this model combines the best of both worlds.

Key Features and Benefits

1. Integrated Filling and Capping System

This machine is designed to streamline the bottling process by combining filling and capping functions into one system. The semi automatic beer bottle filling capping machine minimizes manual handling, improving efficiency while ensuring a consistent, high-quality product.

2. Wide Application Range

The machine is versatile and can handle various bottle sizes, making it ideal for carbonated beverages like craft beer, sparkling water, and sodas. It caters to businesses needing a reliable manual beer bottle filling machine for diverse product lines.

3. Adjustable Filling Accuracy

Precision is crucial in beverage production, and this machine features an advanced filling mechanism that ensures accurate liquid volumes. Whether you are filling a single bottle or multiple units, the semi automatic beer bottle filling machine delivers consistent results every time.

4. Durable and Hygienic Design

Constructed with food-grade stainless steel, the machine ensures durability while meeting stringent hygiene standards. This robust build is ideal for operations seeking a long-term semi automatic beer bottle filling capping machine.

5. Compact and Easy to Operate

The compact design of this machine makes it suitable for smaller production spaces, while its intuitive interface ensures ease of operation for users at all skill levels. This makes it a top choice for businesses looking to integrate a manual beer bottle filling machine without extensive training.

6. Adjustable Capacity

With a production rate of 200-800 bottles per hour, this machine is scalable to meet varying production demands. It’s perfect for small breweries, craft beverage producers, and pilot operations looking for a versatile semi automatic beer bottle filling machine.

Business Advantages

Choosing the MIC Semi Automatic Carbonated Drink Bottle Filling Capping Machine ensures:

Efficiency: The integrated system reduces production time and increases throughput.

Cost Savings: Save on labor costs with automated filling and capping functions.

Quality Assurance: Deliver consistent product quality with precise filling capabilities.

Flexibility: Easily adapt to different bottle sizes and beverage types.

Ideal Applications

This machine is best suited for:

Craft breweries expanding their bottling operations.

Beverage start-ups looking for a cost-effective semi automatic beer bottle filling machine.

Producers of sparkling water and soda who need an adaptable and durable solution.

Why Choose Micmachinery?

As a leading manufacturer in the beverage machinery industry, Micmachinery is committed to delivering high-quality, efficient, and innovative solutions. Our semi automatic beer bottle filling capping machine reflects our dedication to excellence, combining precision engineering with user-focused design.

Contact Us

Explore how the MIC Semi Automatic Carbonated Drink Bottle Filling Capping Machine can transform your production process. Contact Micmachinery today to learn more or request a personalized consultation. Let us help you achieve your production goals with our reliable and professional beverage machinery solutions.

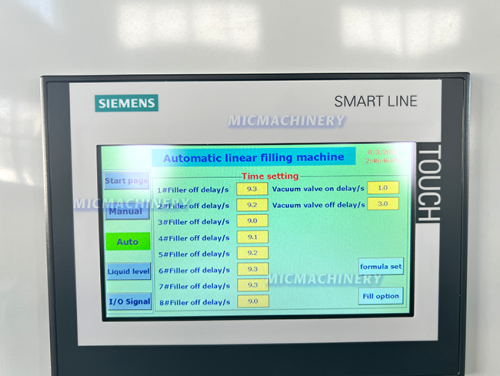

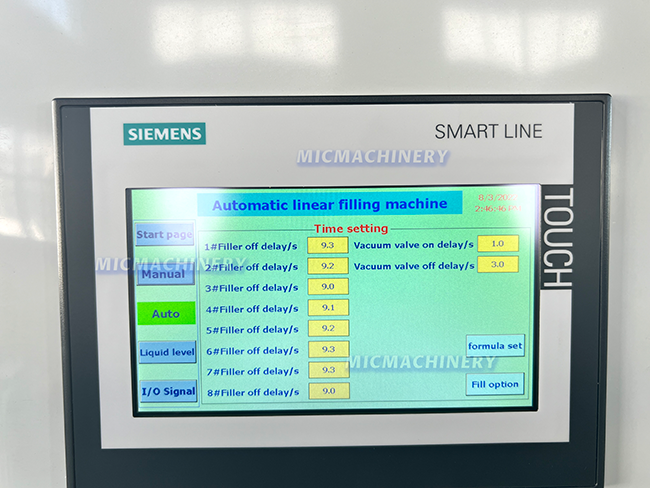

Control Panel

The control panel can control the start and stop of the machine. And It can control the filling speed and filling capacity.It looks more convenient and intuitive

Filling Head

The filling head relies on artesian flow to fill the beer into glass bottles. Filling heads are easy to clean and replace.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Capping Machine

When the glass bottle is finished filling, enter the capping station. Manually place the bottle cap into the screw cap. Then the machine will put a cap on the bottle. Finally, remove the bottle manually

|

Power |

0.3Kw |

|

Filling heads |

4-10 heads |

|

Capping heads |

4-10 heads |

|

Production capacity |

200-800CPH |

|

Bottle diameter range |

Ф50-90MM |

|

Bottle height |

150-300MM |

|

Dimension |

2000*700*2000mm |

|

Weight |

150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment