- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

semi automatic beer glass bottle filling cappingng machine on the basis of independent development of the bottle filling, capping unit.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Are you looking for a reliable and cost-effective solution for your small to medium-sized brewery's beer bottling needs? Micmachinery offers a semi-automatic beer bottle filling and capping machine that can fill and cap up to 200-800 bottles per hour, depending on the size and shape of the bottles.

Our semi-automatic beer bottle filling and capping machine is designed for ease of use and simplicity, making it perfect for small breweries that are just starting out or have limited space. It features a user-friendly interface, automatic filling controls, and an integrated capping machine that seals the bottles with precision and consistency.

With our semi-automatic beer bottle filling and capping machine, you can increase your bottling production output while maintaining the quality of your beer packaging. It's also easy to clean and maintain, which helps to reduce downtime and increase productivity.

At Micmachinery, we're committed to providing high-quality semi-automatic beer bottle filling and capping machines that meet the needs of small to medium-sized breweries. Contact us today to learn more about how our equipment can benefit your brewery and take your beer bottling to the next level.

At Micmachinery, we take pride in offering cutting-edge solutions for the beer production industry. Our MIC Semi-Automatic Beer Bottle Filling Capping Machine is designed to meet the needs of small to medium-scale breweries looking for efficient, reliable, and cost-effective bottling equipment. With a production capacity of 200-800 bottles per hour, this versatile machine is an excellent choice for businesses that require precision in both filling and capping.

Why Choose Our Semi-Automatic Beer Bottle Filling and Capping Machine?

Compact and Efficient Design

The semi-automatic beer bottle filling machine is engineered for ease of use, providing a seamless solution for small-scale breweries, taprooms, or craft beer producers. Designed to handle 200-800 bottles per hour, it balances high efficiency with the flexibility needed for various production volumes. Whether you're just starting or scaling up, this manual beer bottle filling machine offers outstanding value with minimal operational overhead.

Versatile Filling and Capping System

This semi-automatic beer bottle filling capping machine is equipped with a dual function: it fills bottles with beer and immediately seals them with a secure cap. The manual operation of the filling system ensures that beer levels are consistently accurate, while the capping system ensures an airtight seal, preventing beer from spilling or losing its freshness. The system is ideal for bottles of various sizes, making it a versatile option for a range of beer packaging requirements.

User-Friendly Operation

One of the key advantages of the semi-automatic beer bottle filling machine is its intuitive design. The operator simply places the bottle onto the filling station, and the machine takes care of the rest—automatically filling and capping with minimal intervention. The simple operation makes it ideal for breweries with limited staff or for those looking to streamline their production line without the need for fully automated systems. Additionally, the manual beer bottle filling machine allows the operator to have greater control over the filling process, ensuring consistent beer quality in every bottle.

Durability and Quality

Our semi-automatic beer bottle filling capping machine is constructed from high-quality stainless steel, making it durable and easy to maintain. Stainless steel ensures that the machine resists corrosion, so it remains in optimal condition even after prolonged use. This material also meets strict hygiene standards, keeping your beer production in compliance with industry regulations.

Cost-Effective and Low Maintenance

This manual beer bottle filling machine is an economical solution for breweries that need to keep operational costs low without sacrificing performance. Its semi-automatic nature reduces the need for expensive fully automated machines, making it a budget-friendly option for breweries in the early stages or those operating in smaller volumes. Furthermore, the simple design means fewer components are at risk of failure, which translates into reduced maintenance costs over time.

Key Features of the MIC Semi-Automatic Beer Bottle Filling Capping Machine

Filling Capacity: 200-800 bottles per hour, ideal for small to medium-sized breweries.

Dual Function: Simultaneously fills and caps bottles to streamline the production process.

User-Friendly: Simple operation reduces the learning curve, allowing breweries to quickly integrate the machine into their production line.

Versatile: Can handle different bottle sizes and types, offering flexibility in packaging options.

Durable Construction: Made with high-quality stainless steel, ensuring a long lifespan and compliance with hygiene standards.

Manual Control: Operators have full control over the filling process, ensuring precise and consistent fill levels.

Low Maintenance: Minimal components reduce maintenance needs and extend the machine's life.

The Perfect Solution for Small to Medium Breweries

Whether you’re a microbrewery just starting out or an established brewery looking for a flexible and affordable filling system, the MIC Semi-Automatic Beer Bottle Filling Capping Machine is the ideal solution. It offers the perfect balance between ease of use, reliability, and cost-effectiveness. Designed with your brewery’s needs in mind, this machine allows you to efficiently fill and cap bottles with precision, reducing labor and maximizing productivity.

Contact Micmachinery Today

Are you ready to elevate your beer production process with the MIC Semi-Automatic Beer Bottle Filling Capping Machine? Reach out to Micmachinery today for more information or a personalized consultation. Our team of experts is here to guide you through the selection, installation, and maintenance of your equipment, ensuring you get the most out of your investment.

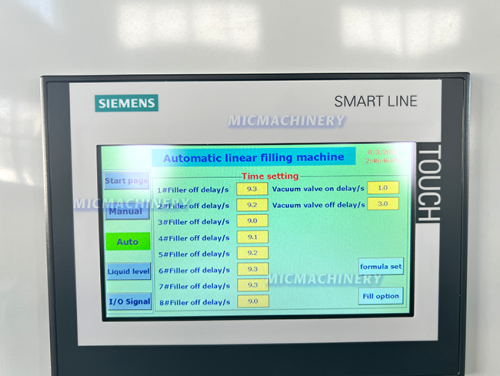

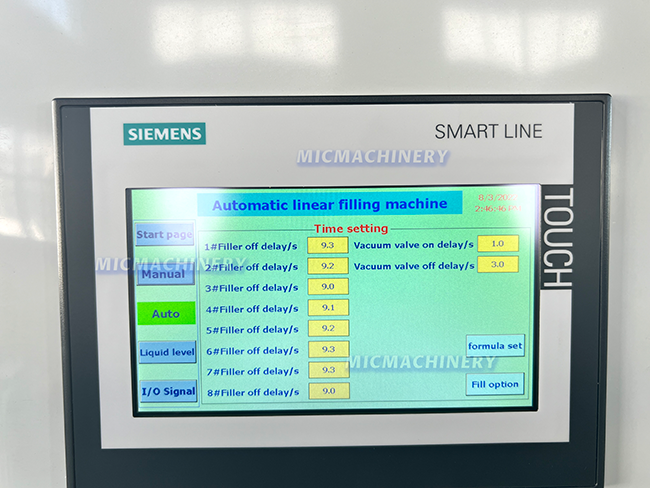

Control Panel

The control panel can control the start and stop of the machine. And It can control the filling speed and filling capacity.It looks more convenient and intuitive

Filling Head

The filling head relies on artesian flow to fill the beer into glass bottles. Filling heads are easy to clean and replace.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Capping Machine

When the glass bottle is finished filling, enter the capping station. Manually place the bottle cap into the screw cap. Then the machine will put a cap on the bottle. Finally, remove the bottle manually

|

Power |

0.3Kw |

|

Filling heads |

4-10 heads |

|

Capping heads |

4-10 heads |

|

Production capacity |

200-800CPH |

|

Bottle diameter range |

Ф50-90MM |

|

Bottle height |

150-300MM |

|

Dimension |

2000*700*2000mm |

|

Weight |

150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment