- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

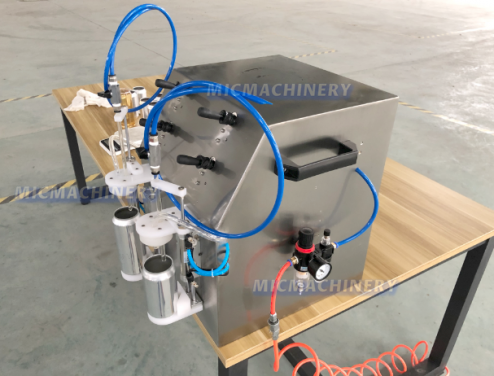

Manual Beer Can Filling Machine is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius)

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the counter pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

At Micmachinery, we specialize in providing high-quality equipment for breweries of all sizes. Our MIC Manual Beer Can Filling Machine is specifically designed to meet the needs of small-scale brewers and microbreweries, offering a reliable and cost-effective solution for filling beer cans with precision and efficiency.

Key Features of the Beer Can Filling Machine

Manual Operation for Precision Control: The beer filling machine is designed for manual operation, giving brewers full control over the filling process. This ensures accurate fill levels and minimal product waste.

Compact and Space-Efficient Design: With its compact footprint, this beer filling machine is ideal for small breweries where space is limited. Despite its size, it offers a consistent and reliable filling process, making it the perfect choice for smaller operations.

Efficient Filling at 8 Cans per Minute: The manual beer filling machine is capable of filling up to 8 cans per minute, making it well-suited for small batches and craft beer production. It offers a balance of efficiency and precision without compromising the quality of the product.

Low Maintenance and Easy to Operate: Designed with simplicity in mind, this beer filling machine is easy to set up and maintain. It has low maintenance requirements and minimal downtime, ensuring your production line stays running smoothly.

Versatile for Various Beverages: While ideal for beer, this beer can filling machine can also be used for other carbonated beverages, such as soft drinks. Its versatility makes it an excellent addition to any small beverage production line.

Why Choose Our Beer Filling Machine?

Ideal for Small-Scale Breweries:Whether you're a craft brewer just starting out or an established microbrewery, this machine provides the perfect filling solution for smaller batches without sacrificing quality or efficiency.

Cost-Effective and Reliable: With its affordable price point and low operational costs, the beer can filling machine is an excellent choice for breweries looking for an economical solution without compromising on quality.

Built to Last: Made with high-quality materials, the beer filling machine is built for durability and longevity. It is designed to withstand the rigors of continuous use, offering long-term reliability for your production needs.

Benefits of the Manual Beer Filling Machine

Precision and Control: Achieve the perfect fill every time with the manual control system. The beer can filling machine is designed to reduce overflows and spillage, maximizing yield and preserving the quality of your product.

User-Friendly Design: With simple controls and a straightforward setup process, the manual beer filling machine is easy to operate, making it an ideal choice for small breweries with limited technical staff.

Quick Turnaround: The filling process is streamlined to minimize bottlenecks, allowing you to quickly fill beer cans and increase your production capacity without compromising quality.

Why Micmachinery?

At Micmachinery, we are dedicated to supporting the success of small breweries with high-performance, cost-effective equipment. The MIC Manual Beer Can Filling Machine exemplifies our commitment to providing reliable solutions for the craft brewing industry. Whether you are just starting or scaling your production, our beer filling machine is designed to grow with you.

If you're looking to streamline your filling process and improve efficiency, get in touch with us today to learn more about the beer filling line solutions we offer. Let Micmachinery help you take your beer production to the next level!

Conclusion

This format presents the same information in a more structured, accessible way, with clear headings, bullet points, and concise descriptions. It also emphasizes the beer can filling machine's key benefits while making the content easy for users to navigate.

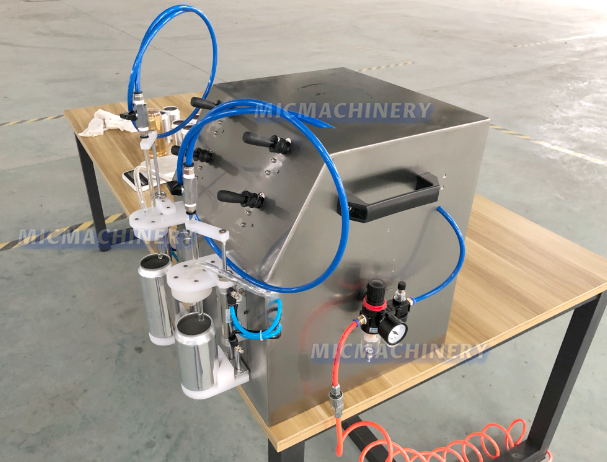

Control Button

Control buttons can control when the machine starts filling and can stop filling manually. It also can change the counter pressure filling valves to normal pressure filling valves.then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

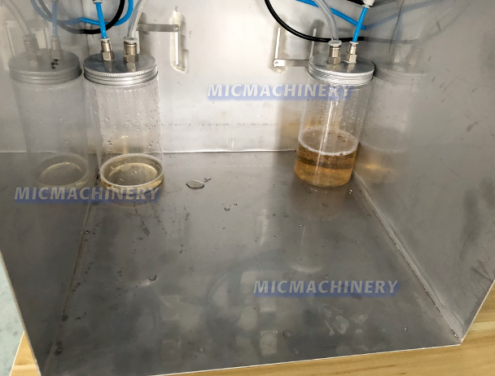

Filling Head

After pressing the button, the filling head enters the inside of the cans and fills the beer into the cans. Filling heads are easy to replace and clean.

| Filling Heads | 2 Pieces |

| Production Capacity | 8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure |

0.4-0.6Mpa |

|

Can Diameter Range |

Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight |

15KG |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment