- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The machine adopts PLC control, according to the filling cup, fixed discharging mouth, the rest all operation can be finished on a touch screen. In addition to have common automatic piston filling machine advantages, also the widened the range of filling material. Such as filling material contains particles, long strips of solid content, also can be a very effective filling.

1. Available with standard conveyor or with pucks for unstable cups

2. Flexible design

3. Very fast and easy changeover of format size

4. Docking filling station model available

5. Anti-dripping filling nozzle

At Micmachinery, we understand the importance of efficiency and precision in beverage production, which is why we offer the MIC Fully Automatic Juice Cup Packaging Machine. Designed for modern juice manufacturers, this innovative packaging machine is ideal for high-volume production lines that require precision, speed, and reliability. Capable of processing 600-800 juice cups per hour, this juice filling machine provides the perfect solution for those looking to scale their juice cup packaging operations.

With its fully automated features and advanced technology, the juice packing machine offers exceptional performance while ensuring the integrity and quality of your juice cups. Additionally, the integration of a juice cap packaging machine ensures that your juice products are sealed securely, preserving their freshness for longer shelf life.

Why Choose the MIC Fully Automatic Juice Cup Packaging Machine?

1. High-Speed, High-Volume Production

The MIC Fully Automatic Juice Cup Packaging Machine is designed for high-efficiency operations, with a capacity of 600-800 juice cups per hour. This means you can meet growing demand while maintaining top-tier quality, making it an excellent choice for businesses looking to optimize their production lines.

2. Automated Juice Filling and Sealing

This advanced juice filling machine ensures that your juice cups are filled accurately and consistently, reducing waste and improving product uniformity. The automated process helps reduce labor costs while increasing operational efficiency. Coupled with the juice cap packaging machine, your juice cups are securely sealed, ensuring no leakage and extending shelf life.

3. Compact and User-Friendly Design

Despite its high production capacity, the juice packing machine features a compact design that makes it suitable for factories with limited space. Its intuitive controls and easy-to-use interface allow your operators to manage the entire packaging process with minimal training, resulting in faster set-up times and fewer operational errors.

4. Versatile Packaging Options

The juice filling machine is highly versatile and can handle various cup sizes, from small single-serve portions to larger family-size containers. This adaptability makes it a great fit for juice producers offering a range of products in different formats. The quick-changeover system ensures that your production line can be easily adjusted without significant downtime.

Key Features of the MIC Fully Automatic Juice Cup Packaging Machine

High-Speed Processing:

With the ability to process 600-800 juice cups per hour, this juice packing machine is designed to keep pace with high-demand production schedules, helping you meet tight deadlines without compromising on quality.

Precision Filling and Sealing:

The juice filling machine uses state-of-the-art filling technology to ensure that each cup is filled with the exact amount of juice, reducing product waste and enhancing the overall consistency of your product. The integrated juice cap packaging machine seals each cup securely, preserving freshness and preventing spills.

Hygienic and Easy to Clean:

Constructed from food-grade stainless steel, the juice packing machine is built for hygiene and durability. Its smooth surfaces and easy-to-remove parts make cleaning and maintenance quick and straightforward, ensuring compliance with the highest sanitation standards.

Energy-Efficient Operation:

This juice filling machine is designed to operate efficiently with low energy consumption, helping to reduce your operating costs while maintaining high production speeds. Its energy-efficient design makes it an environmentally-friendly choice for your packaging needs.

Minimal Maintenance:

The MIC machine is designed to be low-maintenance, with fewer moving parts and a simple system that requires minimal upkeep. This reduces your overall downtime, keeping your production line running smoothly and efficiently.

How the MIC Fully Automatic Juice Cup Packaging Machine Benefits Your Business

1. Increased Productivity

The MIC Fully Automatic Juice Cup Packaging Machine is engineered to boost your productivity with its fast and efficient packaging system. It enables you to produce a large volume of juice cups in a short amount of time, meeting high-demand requirements while keeping costs under control.

2. Enhanced Quality Control

By automating the filling and sealing process, the machine reduces the chances of human error, ensuring each juice cup is consistently filled and securely sealed. This leads to higher product quality and reduces the risk of defective products reaching your customers.

3. Lower Operational Costs

The juice packing machine is not only energy-efficient but also reduces the need for extensive manual labor. This helps lower labor costs, while its high-speed operation ensures that you can keep up with the growing demand for your juice products.

4. Versatility Across Product Lines

Whether you're packaging fruit juices, smoothies, or flavored drinks, this machine provides the flexibility to handle different cup sizes and juice types. The quick changeover system ensures that your production line can be easily adjusted to meet evolving market demands.

Why Choose Micmachinery?

At Micmachinery, we are committed to providing top-quality packaging solutions that enhance your production capabilities. The MIC Fully Automatic Juice Cup Packaging Machine is a testament to our dedication to innovation, efficiency, and reliability. Whether you are a growing juice brand or an established producer, our equipment is designed to scale with your business and help you meet the demands of today’s competitive market.

Contact Micmachinery Today

Take your juice packaging process to the next level with the MIC Fully Automatic Juice Cup Packaging Machine. Contact us today to learn more about how our machines can improve your production line’s efficiency, reduce costs, and ensure high-quality juice packaging.

cup loading station

Put the finished cups into the cup loading station. When the machine receives the start signal, the cup loading station will automatically drop the cups to be filled into the mold accurately, which is convenient for later filling.

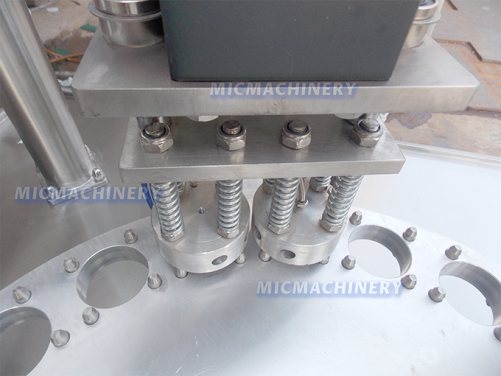

foil loading sucking disks

The device is designed to absorb the sealed tin foil film with a moderate suction force. When the cup reaches the desired position, the two pieces of foil are automatically absorbed and placed on the cup with precision. The working process is time-saving and stable

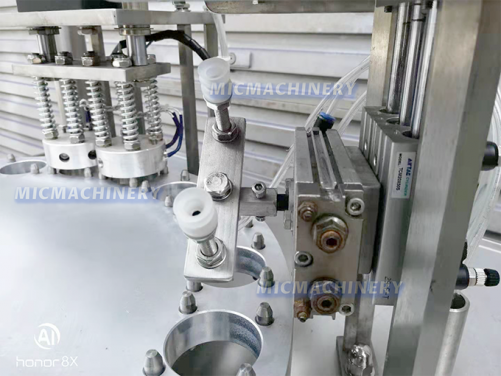

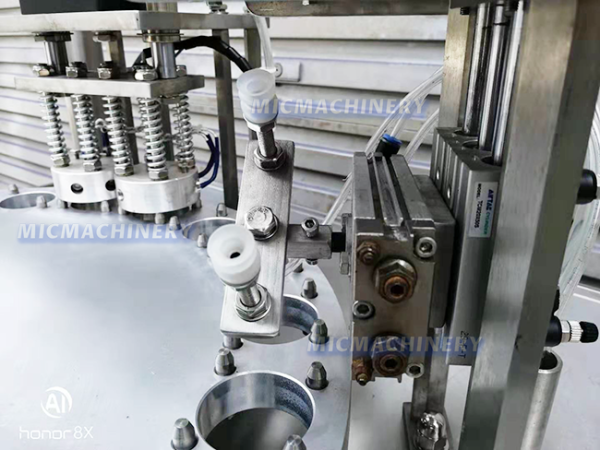

filling head

This machine adopts automatic piston filling, can ensure the precise filling you need filling quantity, the whole process without drip leakage, no waste of materials.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

|

Diameter |

1100*1100*1600mm |

|

Weight |

350KGS |

|

Power |

2 KW |

|

Voltage |

110V/ 60Hz 1P |

|

Air pressure |

0.6-0.8Mpa |

|

Capacity |

600-800 pcs/hour |

|

Air consumption |

0.6m³/min |

|

Heating type |

electrical heated |

|

Working position |

6 |

|

Machine frame |

SUS 304 |

|

Item |

Brand |

|

PLC |

OMRON |

|

Touch Screen |

WEINVIEW |

|

Motor |

DINGYI |

|

Magnetic Valve |

JELPC |

|

AC Contactor |

SCHNEIDER |

|

Temperature Control |

SIMP |

|

Relay, Circuit Breaker |

DELIXI |

|

Divider |

REP |

|

Pneumatic Component |

AKS |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment