- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The machine is suitable for sealing cans of various sizes, the liquid does not overflow during the sealing process, the tank itself does not rotate, and the sealing is closer.

The sealing speed of the machine can reach 1800Pcs/hour, the power is only 0.55KW, and the power consumption is small.

The machine body is small in size, saving space, low in cost but high in efficiency,we can customize the most suitable machine for you according to the different needs of customers

The sealing speed of the machine can reach 1800Pcs/hour, the power is only 0.55KW, and the power consumption is small.

The machine body is small in size, saving space, low in cost but high in efficiency,we can customize the most suitable machine for you according to the different needs of customers

In addition to its sealing capabilities, the soda canning machine enhances operational efficiency. By automating the canning process, this machine significantly reduces the time required for sealing, leading to increased productivity. Its reliable design and precise control mechanisms ensure consistent sealing quality, minimizing product spoilage and optimizing production output. With its high-speed capabilities, the soda canning machine can meet the demands of high-volume production lines, allowing manufacturers to efficiently deliver soda products to consumers.

Introducing the MIC Beverage Can Capping Machine

At Micmachinery, we pride ourselves on providing advanced packaging solutions for the beverage industry. Our MIC Beverage Can Capping Machine, capable of processing up to 30 cans per minute (CPM), is an essential component for any production line focused on efficiency and reliability. Designed with the latest technology, this soda can capping machine ensures your products are securely sealed, maintaining quality and freshness.

Key Features

High-Speed Performance

The soda capping machine operates at an impressive speed of 30 cans per minute, making it an ideal choice for medium-sized production facilities. This high-speed capability not only increases throughput but also enhances your overall operational efficiency.

Precision Engineering

Engineered for accuracy, the soda can capping machine utilizes precision capping technology to ensure each can is sealed perfectly. This minimizes the risk of leaks and guarantees that your beverages maintain their carbonation and flavor integrity.

User-Friendly Interface

Our soda canning machine features a simple and intuitive control panel that allows operators to easily adjust settings and monitor production status. The design minimizes the learning curve, enabling your team to operate the machine with confidence and efficiency.

Versatile Compatibility

The MIC Beverage Can Capping Machine is versatile enough to handle various can sizes and types, making it suitable for a range of beverages, including sodas, energy drinks, and sparkling water. This adaptability is crucial for manufacturers looking to diversify their product offerings.

Robust Construction

Durability is a hallmark of our machinery. Constructed from high-quality materials, the soda capping machine is built to withstand the demands of continuous operation. This robust design results in lower maintenance costs and reduced downtime, ensuring your production line runs smoothly.

Safety Features

Safety is a top priority in our equipment design. The soda canning machine is equipped with multiple safety mechanisms, including emergency stop functions and protective guards, ensuring a safe working environment for your operators.

Conclusion

The MIC Beverage Can Capping Machine is more than just a soda capping machine; it's a reliable partner in your beverage production process. With its high-speed performance, precision sealing technology, and user-friendly design, this machine is the ideal solution for manufacturers looking to enhance their operational efficiency. At Micmachinery, we are committed to delivering top-quality soda canning machines that meet the evolving needs of the beverage industry. Choose us for your can capping solutions and experience unparalleled performance and reliability!

At Micmachinery, we pride ourselves on providing advanced packaging solutions for the beverage industry. Our MIC Beverage Can Capping Machine, capable of processing up to 30 cans per minute (CPM), is an essential component for any production line focused on efficiency and reliability. Designed with the latest technology, this soda can capping machine ensures your products are securely sealed, maintaining quality and freshness.

Key Features

High-Speed Performance

The soda capping machine operates at an impressive speed of 30 cans per minute, making it an ideal choice for medium-sized production facilities. This high-speed capability not only increases throughput but also enhances your overall operational efficiency.

Precision Engineering

Engineered for accuracy, the soda can capping machine utilizes precision capping technology to ensure each can is sealed perfectly. This minimizes the risk of leaks and guarantees that your beverages maintain their carbonation and flavor integrity.

User-Friendly Interface

Our soda canning machine features a simple and intuitive control panel that allows operators to easily adjust settings and monitor production status. The design minimizes the learning curve, enabling your team to operate the machine with confidence and efficiency.

Versatile Compatibility

The MIC Beverage Can Capping Machine is versatile enough to handle various can sizes and types, making it suitable for a range of beverages, including sodas, energy drinks, and sparkling water. This adaptability is crucial for manufacturers looking to diversify their product offerings.

Robust Construction

Durability is a hallmark of our machinery. Constructed from high-quality materials, the soda capping machine is built to withstand the demands of continuous operation. This robust design results in lower maintenance costs and reduced downtime, ensuring your production line runs smoothly.

Safety Features

Safety is a top priority in our equipment design. The soda canning machine is equipped with multiple safety mechanisms, including emergency stop functions and protective guards, ensuring a safe working environment for your operators.

Conclusion

The MIC Beverage Can Capping Machine is more than just a soda capping machine; it's a reliable partner in your beverage production process. With its high-speed performance, precision sealing technology, and user-friendly design, this machine is the ideal solution for manufacturers looking to enhance their operational efficiency. At Micmachinery, we are committed to delivering top-quality soda canning machines that meet the evolving needs of the beverage industry. Choose us for your can capping solutions and experience unparalleled performance and reliability!

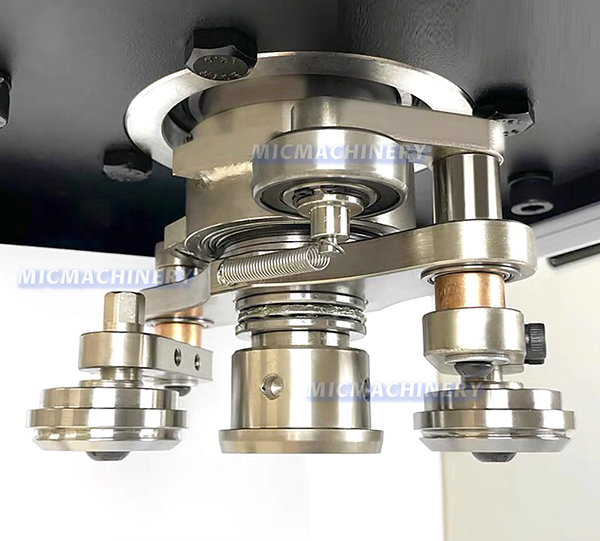

Capping Station

The machine is suitable for sealing cans of various sizes, the liquid does not overflow during the sealing process, the tank itself does not rotate, and the sealing is closer.

Work flow of capping machine

After filling, manually put the lid on, put the can on the tray of the capping machine, open the start button, and the internal device rotates at high speed and spins the cap efficiently.

|

Weight |

52kg |

|

Voltage |

220V 50Hz |

|

Packaging Type |

CANS, Bottles |

|

Dimension |

255*455*608mm |

|

Motor power |

0.55KW |

|

Filling speed |

30 cans each minute |

Products

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

Product Catalog

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment