- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

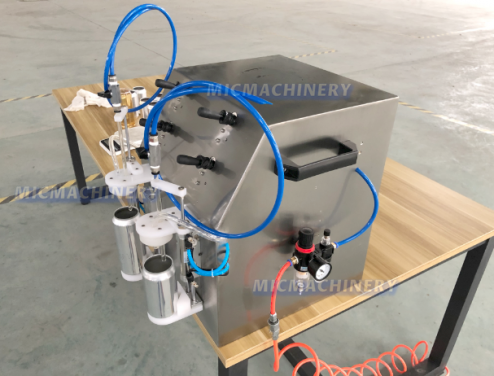

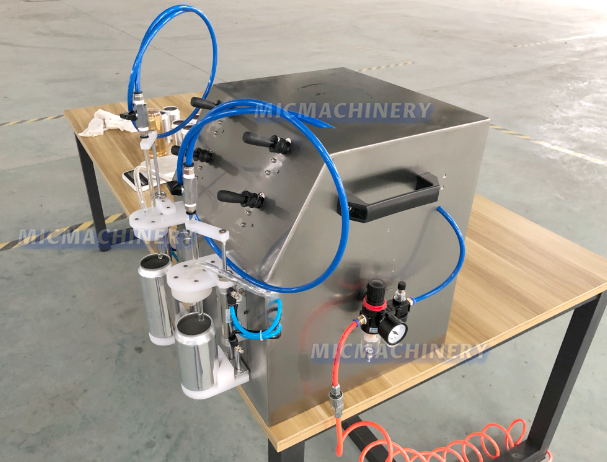

Manual Beer Can Filling Machine is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius)

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the counter pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

Manual soft drink filling machines are simple and easy to operate, and do not require any advanced technical knowledge or training. They typically consist of a container to hold the soft drink, a nozzle to dispense the liquid, and a lever or foot pedal to control the flow of the liquid.

While manual soft drink filling machines are not as efficient as automated machines, they are ideal for small-scale beverage production operations that do not require high-speed output. They are also suitable for operations where multiple types of packaging materials or sizes are used, as the operator can easily adjust the machine settings to accommodate different products.

The key advantage of manual soft drink filling machines is their affordability and ease of use. They are often significantly cheaper than automated machines and require minimal maintenance. They can also be easily integrated into existing production workflows, allowing small-scale manufacturers to package soft drinks efficiently and effectively.

Overall, manual soft drink filling machines are an important tool for small-scale beverage manufacturers who need to fill containers with soft drinks in a simple and cost-effective manner. While they may not have the advanced features or speed of automated machines, they are a valuable resource for small-scale operations.

At Micmachinery, we specialize in designing and manufacturing high-quality beverage production equipment tailored to meet the diverse needs of our clients. The MIC Manual Soft Drink Filling Machine is an ideal choice for businesses seeking reliable, cost-effective solutions for small-scale soft drink production. Whether you’re just starting out or looking to expand, this machine combines affordability, precision, and simplicity, making it a valuable addition to any operation.

Why Choose the MIC Manual Soft Drink Filling Machine?

1. Affordable Pricing

For businesses concerned about the soft drink filling machine price, this model stands out as an economical yet efficient option. Its affordability allows startups and small-scale manufacturers to access professional-grade equipment without exceeding their budget.

2. Compact and Portable Design

With its lightweight and compact structure, this soft drink filling machine is perfect for operations with limited space. The portability also makes it suitable for on-site use at events or mobile production units.

3. User-Friendly Manual Operation

Designed with simplicity in mind, the machine is manually operated, requiring no complex setup or training. It’s easy to use, making it an excellent choice for businesses new to the beverage industry.

4. Versatile Filling Capabilities

The machine is versatile enough to handle various soft drink types, including carbonated beverages, flavored sodas, and sparkling water. This adaptability makes it a valuable asset for producers aiming to diversify their product lines.

5. High-Quality Construction

Built from durable, food-grade materials, the machine ensures hygiene and longevity. Its robust construction guarantees reliable performance over time, even with consistent daily use.

Features of the MIC Manual Soft Drink Filling Machine

Efficient Filling Speed: Capable of filling up to 8 cans per minute, this machine ensures smooth and consistent production.

Accurate Filling Mechanism: Reduces spillage and waste, ensuring every can is filled to the correct level.

Compact Dimensions: Designed to save space without compromising functionality.

Low Maintenance Requirements: Its simple structure means minimal downtime and reduced maintenance costs.

Applications

The MIC Manual Soft Drink Filling Machine is suitable for:

Small-scale soft drink manufacturers.

Businesses venturing into soft drink canning.

Custom or specialty beverage producers focusing on unique flavors.

This machine seamlessly integrates into your production line, complementing other soft drink canning machine components to deliver a complete solution.

Micmachinery: Your Partner in Beverage Production

At Micmachinery, we take pride in providing equipment that combines quality, efficiency, and value. The MIC Manual Soft Drink Filling Machine exemplifies our commitment to helping clients achieve their production goals.

If you’re looking for a soft drink filling machine that offers precision and reliability at an attractive soft drink filling machine price, this model is an excellent choice. Its user-friendly operation and robust performance make it an indispensable tool for soft drink producers.

Contact Us for More Information

Interested in learning more about the MIC Manual Soft Drink Filling Machine? Contact Micmachinery today to discuss your production needs and get a personalized quote. Let us help you take your beverage business to the next level with the right equipment and expertise.

Control Button

Control buttons can control when the machine starts filling and can stop filling manually. It also can change the counter pressure filling valves to normal pressure filling valves.then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

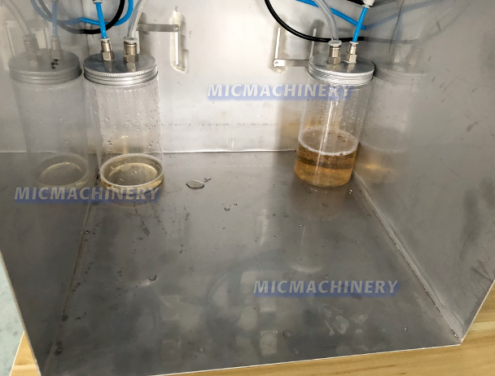

Filling Head

After pressing the button, the filling head enters the inside of the cans and fills the beer into the cans. Filling heads are easy to replace and clean.

| Filling Heads | 2 Pieces |

| Production Capacity | 8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure |

0.4-0.6Mpa |

|

Can Diameter Range |

Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight |

15KG |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment