- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

1 Machine information

Adopt with PLC automatic program circulation control with stable and reliable performance. The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss.

All the transfer system is controlled by frequency changing devices. With stable and smooth transfer speed. Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

The heat shrink film packing machine represents a pinnacle of efficiency and reliability in the packaging industry. As the name suggests, these machines are designed to utilize heat to shrink a film tightly around products, creating a secure and professional-looking package.

Operating as a type of shrinkable packing machine, the heat shrink film packing machine offers versatile performance suitable for a wide range of products and industries. From individual items to bulk quantities, these machines can efficiently package various shapes and sizes with precision and consistency.

Choosing the right shrink packaging machine manufacturer is crucial in ensuring the quality and reliability of the equipment. Reputable manufacturers offer machines built to industry standards, with robust construction and advanced features for optimal performance. Additionally, manufacturers often provide technical support, training, and spare parts to ensure the smooth operation of the equipment.

The wrap shrinking packing machine, another term for the heat shrink film packing machine, emphasizes the process of wrapping products with shrink film and then shrinking it to create a tight seal. This process not only protects the products from external elements but also enhances their presentation, making them more appealing to customers.

The heating shrinkable packing machine refers to the specific function of heating the shrink film to activate its shrink properties. This step is essential for achieving a tight and secure seal around the products, ensuring their protection during handling and transportation.

Moreover, the automatic linear wrap packing machine is a type of heat shrink film packing machine that offers automated operation for increased efficiency and productivity. These machines are equipped with conveyor systems and automated controls that streamline the packaging process, reducing manual labor and minimizing errors.

In summary, the heat shrink film packing machine is a versatile and indispensable tool in modern packaging operations. Alongside other shrinkable packing machine, it ensures the efficient and reliable packaging of products, enhancing their protection and presentation. By choosing a reputable shrink packaging machine manufacturer, businesses can invest in quality equipment that meets their specific needs and contributes to their success in the market.

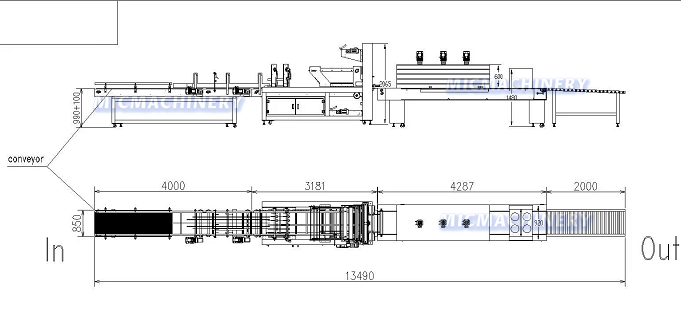

◆ 2 Layout

Technical parameters

|

Dimension for the whole unit |

L13490mm*W1100mm*H2100mm |

|

Thermal shrinkage passage dimension |

L2400mm*W650mm*H450mm |

|

Max package dimension |

L600mm*W400mm*H350mm |

|

Packaging speed |

35Pcs/minute |

|

Transfer belt width |

550mm |

|

Sealing and cutting time/temperature |

0.5-1.5s 180°C-260°C |

|

Operating power supply/power |

380V 30kw |

|

Operating air pressure |

0.6-0.8Mpa |

|

Air Consumption |

0.6m3/minute |

Electrical Configuration

Remark: Our machine use Three phase : 380V/50HZ

If your country electricity is different , please tell me .

|

Item |

Model |

Amount |

Brand |

Origin |

|

Miniature circuit breaker |

4P C20 |

1 |

Schneider |

France |

|

Miniature circuit breaker |

3P C10 |

1 |

Schneider |

France |

|

Miniature circuit breaker |

2P C10 |

1 |

Schneider |

France |

|

A.C.contactor |

E1810 |

1 |

Schneider |

France |

|

A.C.contactor |

E09104 |

3 |

Schneider |

France |

|

PLC |

SIMATIC S7-200 |

1 |

Siemens |

Germany |

|

Touch screen |

SMART 700 IE V3 |

1 |

Siemens |

Germany |

|

Frequency transformer |

SINAMICS V20 |

1 |

Siemens |

Germany |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment