- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Characteristics:

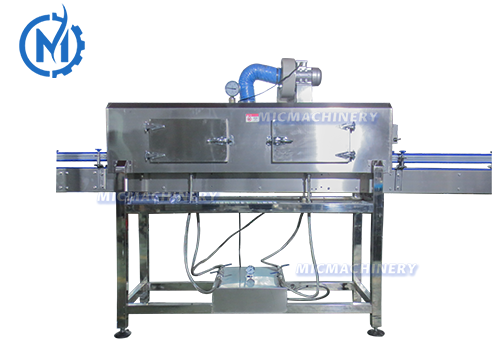

Manually casing the labels, and then the bottle will be passed into the shrink tunnel, and shrink tightly by steam.

Technical parameter :

Size of tunnel: 1.5*0.5*1.6m(can be customized)

Steam generator power: 18kw

Steam shrink tunnel size: 1000*500*500mm

This is the description of heat tunnel for shrink sleeves, shrink sleeve tunnel, manual shrink sleeve machine

The bottle label shrink machine is a cornerstone of packaging operations, offering exceptional performance and precision in applying shrink sleeves onto bottles. As a vital component of shrink sleeve equipment, this machine plays a pivotal role in enhancing product presentation and brand visibility.

At the heart of the bottle label shrink machine is the heat shrink sleeve machine, which ensures precise and reliable shrinkage for seamless label application. With advanced heating mechanisms, this machine guarantees uniform heat distribution, resulting in consistent and high-quality shrinkage of labels around bottles.

The shrink sleeve applicator is another critical component of the shrink sleeve equipment, responsible for accurately applying shrink sleeves onto bottles. Whether it's manually operated or part of an automatic shrink sleeve applicator machine, this apparatus ensures precise label placement, enhancing the overall aesthetics of packaged products.

In addition to its performance, the bottle label shrink machine offers efficiency and speed, making it suitable for high-volume production environments. Its rapid application capabilities enable manufacturers to streamline their labeling processes and meet demanding production targets with ease.

Furthermore, the automatic shrink sleeve applicator machine takes performance to the next level with its automated processes. By reducing manual intervention, this machine enhances productivity and reduces the risk of errors, ensuring consistent and flawless label application on bottles.

In summary, the bottle label shrink machine and its associated shrink sleeve equipment represent the pinnacle of efficiency, precision, and versatility in bottle labeling. From the precision of the heat shrink sleeve machine to the accuracy of the shrink sleeve applicator machine, investing in the right equipment ensures seamless label application and enhances brand recognition in the competitive marketplace.

Terms & Conditions:

Production time: 35-40days(After received samples)

Price: FOB SHANGHAI port.

Payment: 30% payment in advance, 70% balance before shipment. Or L/C

Delivery: 5-8 days after receiving the balance.

Packing: wood case artificial board for export.

Validity: 6 months

Sales After Service:

Guaranty: Two years free spare-parts, lifetime after-sale service

One set of consumable accessories will be provided with the machine.

Before delivery, we will adjust the machine to fit for your product.

Any question, you can mail/call us at any time. And our most experienced engineers is assigned to give consulting service, and always available for dispatching abroad.

All spare parts are always available for delivery.

Manual is in English.

Installation/ Training:

The installation can be provided by the MIC company. It must be after shipment and machine has arrived and factory must be ready equipped with all necessary requirements before booking installation with MIC company. Our engineers will come to the site for the complete and final installation. During the installation session, a one day training course will be provided to the customer to the customer for operation and maintenance procedure. The purchase at US$80/person/day plus all local transportation, accommodation, air tickets (round trip). Day charges include travel days.

Special offer that we can also provide our Sales as translator to your site help the installation and Training. Only to provide the local transportation, accommodation, air tickets (round trip) for Sales will be fine.

Thank you for choosing MIC Company.

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment