- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The brewing industry has evolved significantly, and one critical aspect of modern operations is efficient packaging, particularly through canning. If you're in the market for a beer canning machine for sale, there are several key factors to consider, such as speed, automation, and the ability to handle various can sizes. These machines are designed to streamline the canning process, ensuring your beer is consistently filled, sealed, and packaged with precision. High-performance beer canning machines allow breweries to meet production demands without compromising on the quality of the final product.

For smaller or specialized operations, a craft beer canning machine is an ideal solution. These machines are tailored for small- to medium-sized breweries that focus on high-quality, artisanal beer production. Craft beer canning machines combine ease of use with precision, ensuring that each can is filled with the perfect amount of product while maintaining minimal oxygen levels to preserve the beer’s freshness. They are often more compact than industrial canning lines, making them well-suited for craft breweries looking to balance efficiency with space constraints.

Understanding the beer canning machine cost is an important consideration for breweries of all sizes. The price of a canning machine depends on several factors, including automation level, speed, and capacity. For larger operations, investing in a high-speed, fully automated beer canning machine can increase production output and efficiency, justifying the higher initial investment. Smaller breweries may opt for semi-automatic machines, which come at a lower cost but still offer reliable performance for moderate production volumes. It’s essential to evaluate your production needs and budget to determine which solution offers the best value for your business.

In conclusion, whether you're searching for a beer canning machine for sale, evaluating the features of a craft beer canning machine, or determining the beer canning machine cost, choosing the right equipment is crucial for optimizing your packaging process. These machines play a vital role in ensuring your beer is packaged efficiently and consistently, helping to maintain product quality while meeting consumer demand.

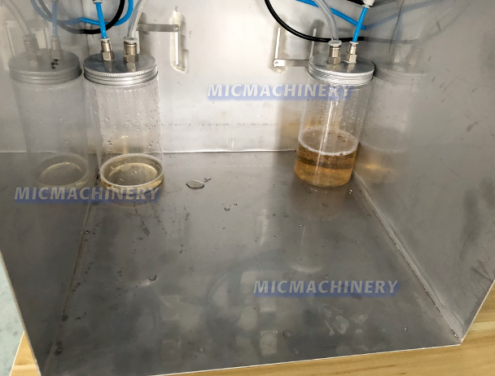

Manual Canning Machine for Drinks is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius)

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the counter pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

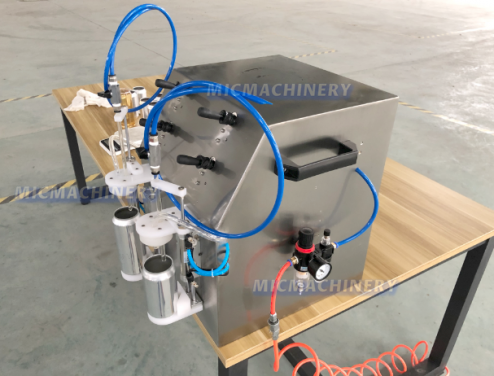

At Micmachinery, we are dedicated to providing advanced solutions tailored for the brewing industry. Our MIC Beer Canning Machine, designed for craft brewers, stands out with its capacity of 8 cans per minute (CPM), making it an essential tool for any brewery looking to scale production while maintaining exceptional quality.

Precision and Performance

The craft beer canning machine is engineered for precision, ensuring that every can is filled to the exact specifications required for your unique brews. With advanced filling technology, this machine minimizes foam during the filling process, preserving the integrity and flavor of your craft beer. Each can is sealed securely, ensuring freshness and reducing the risk of oxidation, which is critical for maintaining the quality of your beverages.

Compact Design for Small Breweries

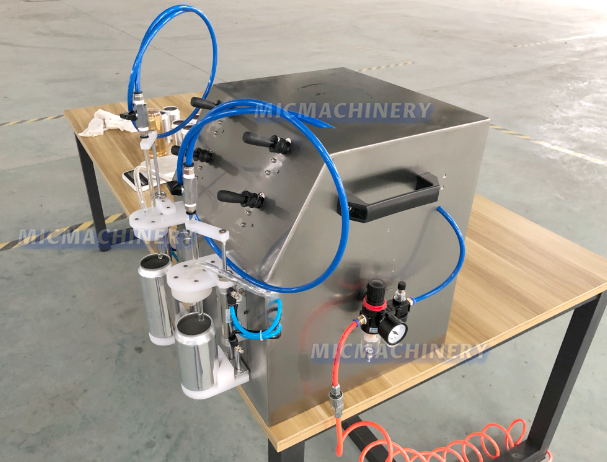

Recognizing the space constraints often faced by smaller breweries, the MIC Beer Canning Machine features a compact design that fits seamlessly into any production area. Despite its smaller footprint, this beer canning machine for sale does not compromise on efficiency or performance. It allows craft brewers to efficiently can their beers without the need for extensive modifications to their existing setup.

User-Friendly Operation

One of the highlights of our beer canning machine is its user-friendly interface. Designed for ease of operation, it allows brewers to quickly set up and start production with minimal training. Operators can easily monitor the filling process, adjust settings, and perform maintenance tasks, all of which contribute to a smoother workflow.

Cost-Effective Solution

When considering the beer canning machine cost, our MIC model offers exceptional value for small to mid-sized breweries. With its combination of advanced technology and reliable performance, this machine provides an economical solution for breweries looking to enhance their canning capabilities without breaking the bank. By investing in this equipment, brewers can significantly increase their production capacity while keeping operational costs in check.

Durability and Hygiene

Crafted from high-quality materials, the MIC Beer Canning Machine is built to last. Its robust construction ensures durability in busy production environments, while the design facilitates easy cleaning and maintenance. This focus on hygiene is paramount for breweries that adhere to strict health and safety regulations, allowing you to focus on brewing great beer without concerns about equipment reliability.

Conclusion

In summary, the MIC Beer Canning Machine for Sale (8CPM) is an ideal choice for craft breweries looking to streamline their production processes. With its precision filling capabilities, compact design, user-friendly operation, and cost-effective pricing, this craft beer canning machine is designed to meet the needs of modern brewers. Trust Micmachinery to support your brewing ambitions with innovative technology that enhances quality and efficiency. Choose the MIC Beer Canning Machine and elevate your canning operations today!

Control Button

Control buttons can control when the machine starts filling and can stop filling manually. It also can change the counter pressure filling valves to normal pressure filling valves.then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

Filling Head

After pressing the button, the filling head enters the inside of the cans and fills the beer into the cans. Filling heads are easy to replace and clean.

| Filling Heads | 2 Pieces |

| Production Capacity | 8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure |

0.4-0.6Mpa |

|

Can Diameter Range |

Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight |

15KG |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment