- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The sealing speed of the machine can reach 1800Pcs/hour, the power is only 0.55KW, and the power consumption is small.

The machine body is small in size, saving space, low in cost but high in efficiency,we can customize the most suitable machine for you according to the different needs of customers

Looking for an efficient and reliable way to cap your beer cans by hand? Look no further than Micmachinery and our manual beer can capping machine. Our equipment is perfect for small craft breweries or homebrewers who want to maintain control over the capping process and ensure that their beer remains fresh and flavorful.

Our manual beer can capping machine can cap up to 30 cans per minute, making it a fast and efficient way to seal your cans. The compact and lightweight design of our machine also makes it easy to use and transport, whether you're capping cans in your garage or at a beer festival.

At Micmachinery, we understand the importance of quality craftsmanship in the beer-making process. That's why we've designed our manual beer can capping machine with durable materials that are built to last. You can trust that our machine will continue to meet your capping needs for years to come.

We're also committed to providing exceptional customer service and support. Our team of experts is available to answer any questions you may have and to help you get the most out of your manual beer can capping machine.

Don't let a lack of resources hold you back from capping your beer cans with precision and consistency. Contact Micmachinery today to learn more about how our manual beer can capping machine can help you achieve your goals and take your beer to the next level.

Efficient canning is a critical component of the brewing process, ensuring that beer is packaged securely and preserved for freshness. A beer can sealer machine is a specialized device designed to provide a reliable seal for cans, which is crucial for maintaining the integrity of the product. This machine ensures that cans are sealed tightly, preventing leaks and contamination while preserving the flavor and quality of the beer. The performance of a beer can sealer machine is pivotal in achieving consistent and secure can closures, making it an essential tool for any brewery focused on quality control and efficiency.

For smaller-scale operations or budget-conscious brewers, a manual beer canning machine offers a practical solution. This type of machine requires hands-on operation for filling and sealing cans, providing a cost-effective way to manage low to moderate production volumes. The performance of a manual beer canning machine is characterized by its simplicity and affordability, allowing brewers to achieve accurate fills and seals without the need for complex automation. While manual canning machines are less automated, they are highly valued for their reliability and ease of use in smaller production settings.

The tabletop beer canning machine bridges the gap between manual and fully automated systems. Designed to fit on a workbench or table, this compact machine offers the benefits of efficiency and ease of use in a space-saving design. A tabletop beer canning machine typically integrates filling and sealing functions, making it an excellent choice for small to mid-sized breweries that require flexibility and precision without occupying significant floor space. The performance of a tabletop beer canning machine includes high accuracy in filling and sealing, combined with the convenience of a compact and user-friendly design.

In summary, the beer can sealer machine, manual beer canning machine, and tabletop beer canning machine each provide distinct advantages depending on the size and needs of the brewery. By understanding the performance characteristics and applications of these machines, brewers can select the most appropriate canning solution to enhance their production efficiency, maintain high quality, and meet their specific operational requirements.

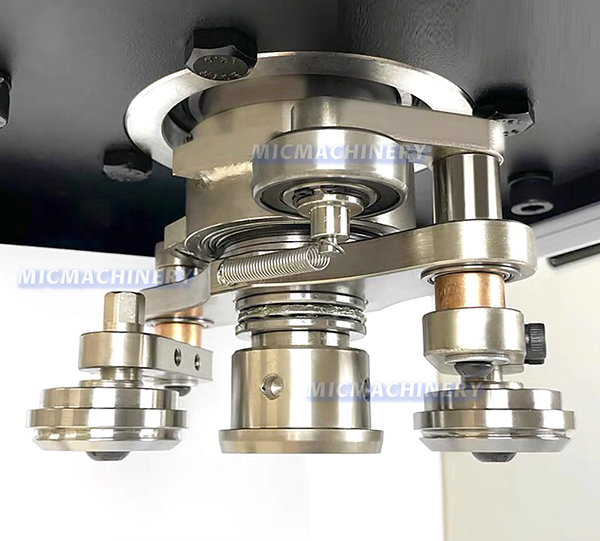

Capping Station

The machine is suitable for sealing cans of various sizes, the liquid does not overflow during the sealing process, the tank itself does not rotate, and the sealing is closer.

Work flow of capping machine

After filling, manually put the lid on, put the can on the tray of the capping machine, open the start button, and the internal device rotates at high speed and spins the cap efficiently.

|

Weight |

52kg |

|

Voltage |

220V 50Hz |

|

Packaging Type |

CANS, Bottles |

|

Dimension |

255*455*608mm |

|

Motor power |

0.55KW |

|

Filling speed |

30 cans each minute |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment