- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

In the vast landscape of label substrates, the bopp labeling machine and opp labeling machine emerge as essential tools for industries navigating the complexities of diverse materials. From the robustness of BOPP (Biaxially Oriented Polypropylene) to the clarity of OPP (Oriented Polypropylene), these machines are adept at accommodating a wide range of label substrates, ensuring precise application and enhancing product presentation across various sectors.

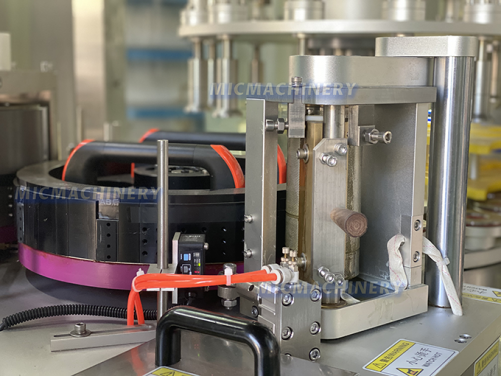

In specialized environments where precision and reliability are paramount, the opp hot melt labeling machine takes center stage. Engineered to excel in applying labels using hot melt adhesive onto OPP substrates, this machine delivers impeccable performance, ensuring labels adhere securely and maintain their integrity throughout the product lifecycle.

Meanwhile, the stalwarts of the labeling industry, the hot melt labeling machine and hot melt glue labeling machine, continue to reign supreme in sectors where hot melt adhesive is the adhesive of choice. Renowned for their efficiency and reliability, these machines are the workhorses of high-speed production lines, delivering precise label application with unwavering consistency.

However, amidst the dominance of hot melt adhesive, the hot glue labeling machine offers a compelling alternative. With its ability to handle various label materials and provide secure adhesion using hot glue, this machine emerges as a versatile option for industries seeking reliable labeling solutions that diverge from the traditional hot melt adhesive approach.

In summary, the world of industrial labeling machinery is rich and diverse, with each machine type offering its own unique advantages and capabilities. From the precision of the opp hot melt labeling machine to the versatility of the hot glue labeler, these machines play a pivotal role in enhancing product presentation, brand integrity, and operational efficiency across a myriad of industries.

1. Containers are gathered by the infeed starwheel and conveyed to the container table. Rotation of the containers initiates once they are situated between the container plates and centering bells.

2. The speed of the feed roller is adjusted to accommodate the necessary label length, ensuring continuous web tension. An integrated threading unit guarantees optimal film feed. In the cutting unit, labels are precisely severed using a PLC command and servo-motor, ensuring an exact cut-off point.

3. Two narrow strips of hot melt glue are used to join the labels together. These strips are applied by a heated glue roller to both the leading and trailing edges of the labels. The label containing the glue strip on its leading edge is then transferred onto the container, ensuring precise label positioning and a secure bond. As the container rotates during label transfer, the labels are tightly applied. Gluing of the trailing edge ensures proper bonding.

|

Transportation institution |

750W, inverter speed control |

|

Conveyor |

industrial nylon chain plate conveyor |

|

Mainframe transportation institution |

2.2Kw |

|

Sub bottle institution |

industrial worm sub bottle institution |

|

Into bottle institution |

with worm sub bottle institution and starwheel position feeding institution to ensure the accuracy and stability of loading |

|

Position institution |

Mechanical pre-location , using the camwheel institution to planish the bottle for label positioning |

|

Labeling institution |

Containers are pick up by rotary wheel ,labeling during the rotation. |

|

Supply label institution |

high speed servo opp label supply system (drive by servo-motor) |

|

Pressing label institution |

Arc brush unit |

|

Guided bottle institution |

adjust by double coordinate section guide rail |

|

Glue supply system |

hot melt glue supply system(German Siemens control system) ensures the accuracy and uniformity of gluing |

|

Safety protection |

In order to keep the operator safety ,when the machine is running please close the protective doors |

|

Lack of label alarm |

Set an alarm to remind the operator to change the label when the label will be use out |

|

Lack of bottle alarm |

When lack of the bottle the machine will stop and make an alarm .The machine will restart automatically as soon as the bottles have been put that will facilitate on-line production |

|

Leak of labeling alarm |

To control the quality of labeling |

|

Pressure testing |

When the pressure can not meet the equipment requirement ,the machine will stop to against bad products produce |

|

Vacuum testing |

When the vacuum can not meet the equipment requirement ,the machine will stop to against bad products produce |

|

Temperature testing |

When the temperature can not meet the equipment requirement , the machine will stop to against bad products produce |

|

Name |

8 heads hot melt glue labeling machine |

|

Power supply |

Three-phase 380V 60 Hz 5W |

|

Machine dimensions: |

2150mm×1700mmX 2010mm(can be adjusted) |

|

Method of speed adjustment: |

uninterrupted - adjust rate |

|

Labeling precision: |

±1mm |

|

Labeling speed |

10000bph |

|

Maximum label width: |

200mm(standard width, can be adjusted ) |

|

Maximum outer diameter of label |

600mm |

|

Paper core Hot melt |

152 mm |

|

Labeling glue: |

glue at both ends of each label with hot melt |

|

Gluing temperature: |

120~160℃ |

|

Labeling type for products: |

suitable for round or square containers made of plastic, metal, glass |

|

Type of label: |

bopp 、paper-plastic composite film 、paper label |

|

Labeling stations: |

customizable |

|

Machine weight: |

about 2000 kg |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Beverage Processing Equipment

- Auxiliary equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Other Types Of Labeling Machines

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Blowing Filling Capping Machine

- Can filling machine

- Beverage Processing Equipment

-

Auxiliary equipment