- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

semi automatic juice Bottling machine on the basis of independent development of the bottle filling, capping unit.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

The semi automatic juice filling machine is designed to streamline the filling process while allowing operators to actively participate in the operation. It typically consists of a filling nozzle, a control panel, and a bottle positioning system.

To operate the machine, an operator manually positions an empty bottle beneath the filling nozzle. The machine then initiates the filling process, with the juice being dispensed into the bottle through the filling nozzle. The operator has control over the filling speed and can monitor the filling levels to ensure accuracy.

Once the desired fill level is reached, the operator manually removes the filled bottle and replaces it with an empty one. This manual bottle exchange process allows for flexibility in filling different sizes or types of bottles, accommodating various production needs.

The semi automatic juice filling machine is known for its simplicity, ease of use, and versatility. It is suitable for small to medium-scale juice production operations or those requiring frequent changeovers. The machine is often employed in research and development settings, pilot production runs, or facilities with limited production space.

While the semi automatic juice filling machine requires some operator involvement, it still offers significant benefits. It improves the efficiency of the filling process, reduces manual labor, and ensures consistent fill volumes. The machine is also cost-effective, as it requires a lower initial investment compared to fully automatic systems.

However, it's important to note that the semi-automatic juice filling machine may not offer the same level of speed and throughput as fully automatic counterparts. Additionally, it may not incorporate advanced features such as capping or labeling systems, which would need to be performed manually or through separate equipment.

In summary, a semi automatic juice filling machine provides a practical and cost-effective solution for filling juice into bottles or containers. It combines manual operation with automated functionality, allowing operators to actively participate in the process while streamlining production. Its versatility, ease of use, and flexibility make it an ideal choice for small to medium-scale juice production operations.

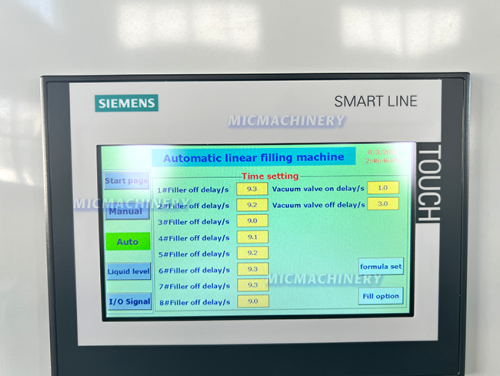

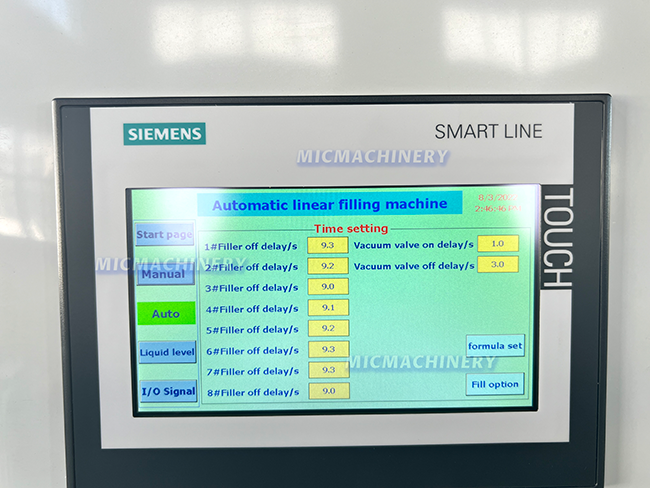

Control Panel

The control panel can control the start and stop of the machine. And It can control the filling speed and filling capacity.It looks more convenient and intuitive

Filling Head

The filling head relies on artesian flow to fill the beer into glass bottles. Filling heads are easy to clean and replace.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Capping Machine

When the glass bottle is finished filling, enter the capping station. Manually place the bottle cap into the screw cap. Then the machine will put a cap on the bottle. Finally, remove the bottle manually

|

Power |

0.3Kw |

|

Filling heads |

4-10 heads |

|

Capping heads |

4-10 heads |

|

Production capacity |

200-800CPH |

|

Bottle diameter range |

Ф50-90MM |

|

Bottle height |

150-300MM |

|

Dimension |

2000*700*2000mm |

|

Weight |

150Kg |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine