- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

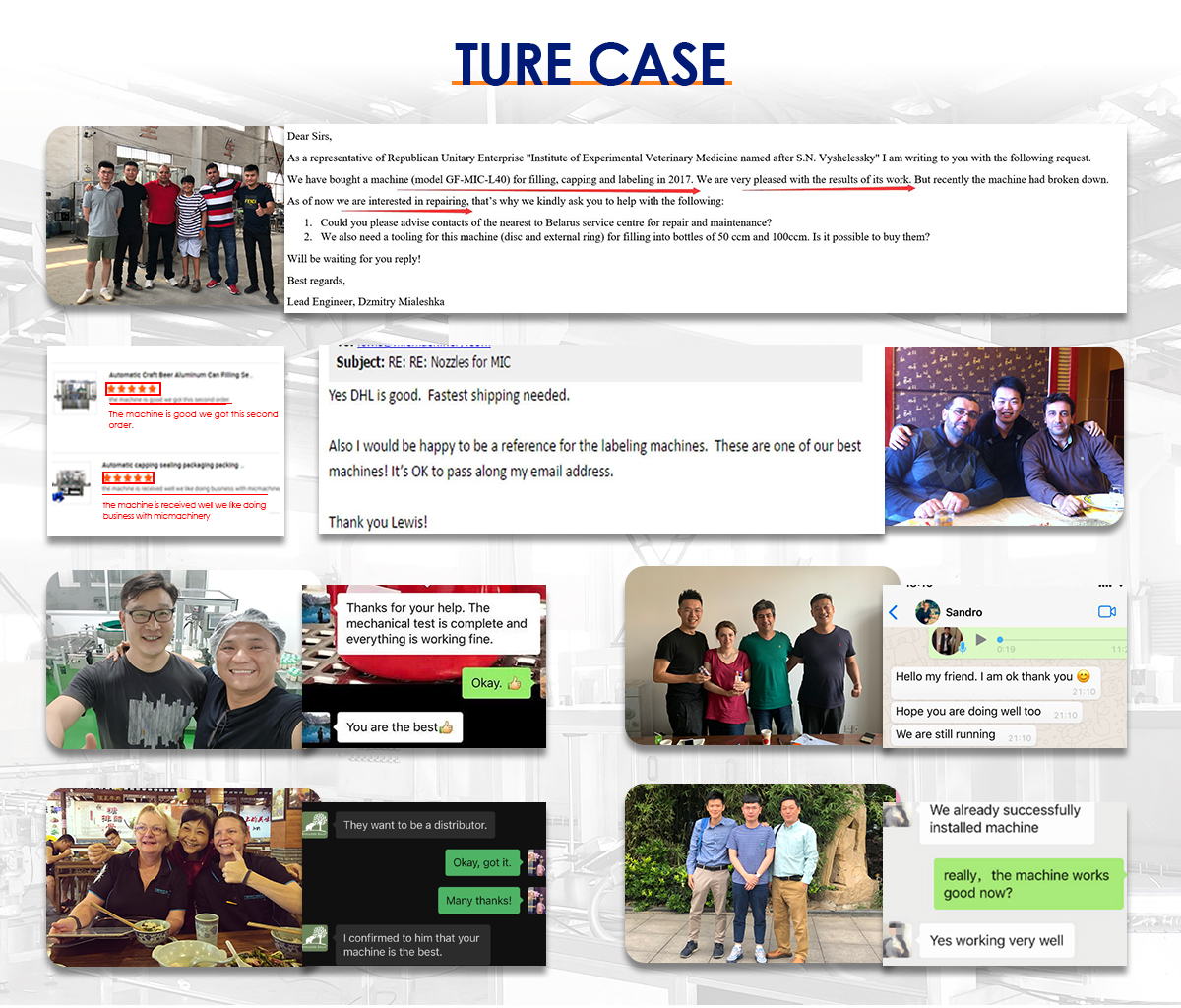

- Customer reviews: click on

MIC 12-12-1 Juice Glass Bottle Filling Machine is applicable for juice glass bottle filling machine for mango juice, litchi juice , orange juice, apple juice and other Fruit and vegetable juice etc. (if need hot filling temperature at 85-90 degree)

Adopt products: mango juice, litchi juice , orange juice, apple juice and other Fruit and vegetable juice etc juice products.

Machine working principle:

The series of products are the aseptic filling equipment for the mango juice, litchi juice , orange juice, apple juice and other Fruit and vegetable juice, designed and developed on the basis of introducing the technology from Germany and combining the features in the production industry of pure beer in China. This machine is of good reliability of mechanical operation, perfect functions in rinsing, filling, capping, disinfecting and sterilizing, realizing filling the sterile beer into the sterile container in a sterile environment

For this production line you might be interested in:

Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine, juice glass packing machine.

As an automatic juice glass packing machine, it eliminates the need for manual intervention, ensuring a seamless and hands-free operation. From container feeding to filling and sealing, the machine takes care of each step with precision and consistency. This automation not only reduces labor costs but also increases production output, allowing juice manufacturers to meet high-volume demands effortlessly.

The juice glass packing machine is specifically designed for packaging juice in glass containers, offering a secure and visually appealing presentation. It handles the entire packaging process, from placing the empty glass containers onto the conveyor to filling them with juice and sealing the lids. The machine can accommodate various sizes and shapes of glass containers, providing flexibility to meet specific packaging requirements.

With its advanced filling mechanism, the juice glass packing machine ensures accurate and consistent filling of juice into the glass containers. Utilizing precision nozzles and advanced flow control technology, it minimizes product wastage and maintains the desired fill levels. This guarantees product consistency and eliminates the risk of underfilled or overfilled containers.

The sealing process of the juice glass packing machine ensures a tight and reliable seal on each glass container, preserving the freshness and quality of the juice. The machine incorporates sealing mechanisms that securely apply caps, lids, or other closures onto the glass containers. This ensures product integrity and prevents leakage, enhancing customer satisfaction.

When it comes to the juice glass packing machine price, it varies depending on factors such as production capacity, features, and customization options. Manufacturers offer different models and configurations to suit varying budget requirements. Investing in an automatic juice glass packing machine can lead to long-term cost savings through improved efficiency, reduced product waste, and increased productivity.

In summary, the juice glass packing machine is a valuable asset for juice manufacturers seeking an efficient and precise packaging solution for their glass containers. With its advanced automation, accurate filling, and reliable sealing capabilities, it streamlines the production process and ensures the integrity of the packaged juice. Whether you need an automatic juice glass packing machine or are considering the juice glass packing machine price, this equipment provides a comprehensive solution for efficient and high-quality juice packaging.

Filling Part

Filling part is mainly composed of filling barrel, filling valve (low temperature and isobar filling), filling pump, bottle hanging device / bottle pedestals, guide rail, elevating device, liquid indicator, pressure gauge, pressure regulator, etc.Rotary wheel fully made of stainless steel SUS 304. Filling valves are made of SUS316L. Filling valves are reasonably structured with accurate filling. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Capping Part

Capping part is mainly composed of capping heads, cap loader (separated), cap unscrambler, cap drop rail, pressure regular, cylinder and also we need an air compressor as the auxiliary external equipment.Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. The capper is equipped with inlet bottle detection switch.

| Model | MIC-12-12-1 |

|---|---|

| Washing heads | 24pcs |

| Filling heads | 24pcs |

| Capping heads | 6pcs |

| Volume | 0.1-1.5L |

| Production capacity | 5000-12000bottle/hr base on 500ml |

| Filling method | Normal pressure |

| Power | 3.5kw 380V/50HZ(According to customer) |

| Air pressure | 0.7Mpa |

| Gas consumption | 0.8m³/min |

| Water consumption for bottle washing | 0.5-1T/H |

| Washing time | 1.5s~2s |

| Wash bottle water pressure | 0.2~0.25 Mpa |

| Weight | 4500kg |

| Dimension | 3500×1800×2500mm |

| Electrical configuration | |

|---|---|

| Touch screen | DELTA |

| Frequency converter | MITSUBISHI |

| PLC | MITSUBISHI |

| Contactor, breaker | DELIXI |

| Proximity switch | DELIXI |

| Photoelectric switch | DELIXI |

| Bearing | Harbin |

| Relay | OMRON |

| Barometer | AirTAC |

| Air cylinder | AirTAC |

| Solenoid valve | AirTAC |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine