- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

semi automatic beer glass bottle filling cappingng machine on the basis of independent development of the bottle filling, capping unit.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

If you're looking for a manual beer bottle filling line that can handle 200-800 bottles per hour, you have several options to choose from. Whether you're just starting out with your homebrewing hobby or looking to expand your craft beer business, there's a manual filling line that will fit your needs.

One option is a manual 2-spout beer bottle filler that can fill up to 300 bottles per hour. This machine is easy to use and requires minimal maintenance, making it a great choice for small-scale operations. It's also designed to handle a variety of bottle sizes and shapes, so you can fill everything from standard beer bottles to unique craft beer bottles.

Another option is a manual gravity-fed bottle filler, which can fill up to 200 bottles per hour. This type of machine is simple and easy to operate, making it a popular choice for homebrewers and small craft breweries. It uses gravity to fill the bottles, so there's no need for electricity or complicated machinery.

For those looking to fill a higher volume of bottles, a manual 4-spout beer bottle filler may be the best option. This machine can fill up to 800 bottles per hour, making it a great choice for small to medium-sized breweries. It's also designed to minimize oxygen pickup during the filling process, ensuring that your beer stays fresh and flavorful.

No matter which manual beer bottle filling line you choose, be sure to follow proper sanitation and cleaning procedures to ensure the quality and safety of your beer. With the right equipment and attention to detail, you can produce high-quality craft beer that your customers will love.

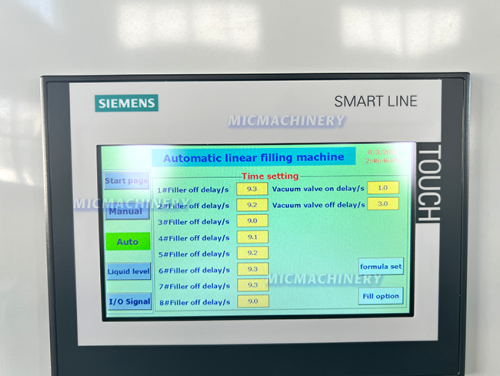

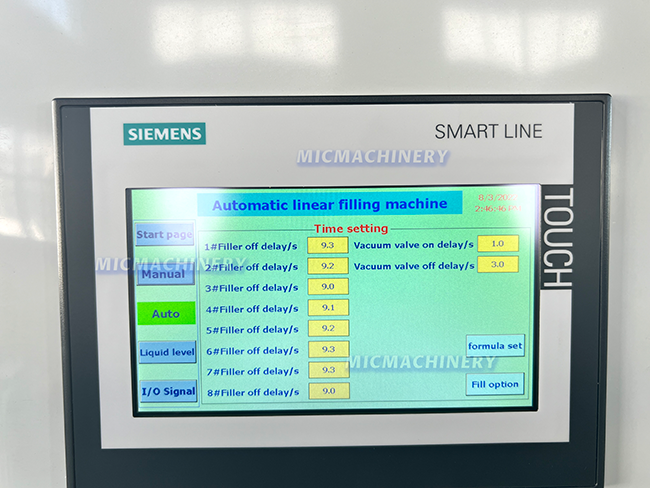

Control Panel

The control panel can control the start and stop of the machine. And It can control the filling speed and filling capacity.It looks more convenient and intuitive

Filling Head

The filling head relies on artesian flow to fill the beer into glass bottles. Filling heads are easy to clean and replace.

This machine adopted negative pressure or isobaric filling system, suitable for beer, wine and etc. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small breweries.

Capping Machine

When the glass bottle is finished filling, enter the capping station. Manually place the bottle cap into the screw cap. Then the machine will put a cap on the bottle. Finally, remove the bottle manually

|

Power |

0.3Kw |

|

Filling heads |

4-10 heads |

|

Capping heads |

4-10 heads |

|

Production capacity |

200-800CPH |

|

Bottle diameter range |

Ф50-90MM |

|

Bottle height |

150-300MM |

|

Dimension |

2000*700*2000mm |

|

Weight |

150Kg |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Other Types Of Labeling Machines

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Empty Can Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Beverage Processing Equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Other Types Of Labeling Machines

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Empty Can Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Can filling machine

- Beverage Processing Equipment