- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

Manual Soda Canning Machine is applicable for Soda drink, carbonated beverage, soft drink, soda water, sparkling water and other canned drinks (Cold filling temperature at 0-4 degrees Celsius)

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the counter pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

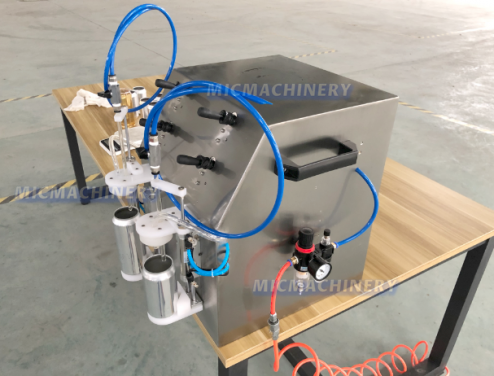

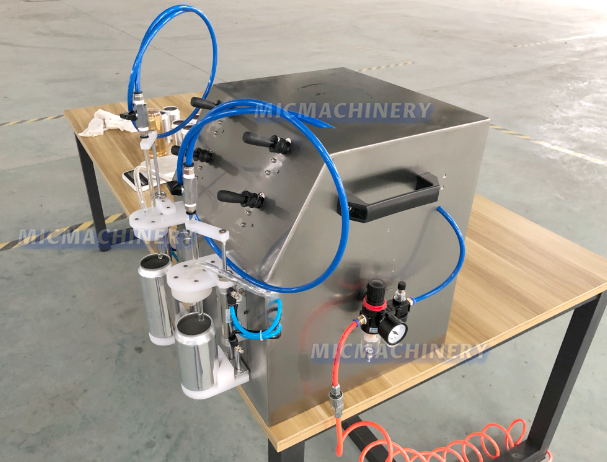

At Micmachinery, we are proud to present the MIC Manual Soda Can Filling Machine, a versatile and efficient solution designed for small-scale beverage producers. With a capacity of 8 cans per minute (CPM), this soda can filling machine is perfect for craft beverage makers, startups, and small operations looking to streamline their canning process while maintaining high product quality.

The MIC Manual Soda Can Filling Machine is built with durability in mind. Constructed from high-quality materials, this soda canning machine is designed to withstand regular use, ensuring longevity and reliability in your production line. Its robust design not only enhances performance but also simplifies maintenance, allowing for easy cleaning and servicing.

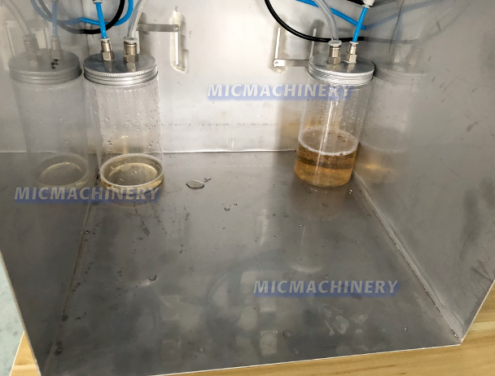

One of the key features of this machine is its user-friendly operation. Designed for manual filling, the MIC soda filling machine allows operators to have complete control over the filling process. This hands-on approach ensures accurate fill levels, minimizing waste and maintaining consistency in every can. The precise filling mechanism is essential for preserving the quality of your beverages, whether you’re canning soda, sparkling water, or other carbonated drinks.

The MIC Manual Soda Can Filling Machine is also adaptable, capable of handling various can sizes. This flexibility allows manufacturers to diversify their product offerings and respond to changing market demands without significant investment in new equipment. Transitioning between different products is seamless, making this machine a valuable asset for any beverage production operation.

Safety and hygiene are paramount in beverage production, and the MIC soda can filling machine is designed with these principles in mind. Its smooth surfaces and simple design facilitate thorough cleaning, ensuring compliance with health and safety regulations. By prioritizing hygiene, you can assure your customers of the quality and safety of your products.

In addition to its filling capabilities, the MIC Manual Soda Can Filling Machine can be paired with a soda canning machine for a complete canning solution. This integration allows for efficient sealing and labeling, streamlining the entire production process from filling to final packaging. This comprehensive approach highlights Micmachinery’s commitment to providing innovative solutions tailored to our clients' needs.

When investing in a soda filling machine, it’s important to consider not only performance but also cost-effectiveness. The MIC Manual Soda Can Filling Machine offers a practical solution for small-scale producers looking to optimize their operations without breaking the bank. Its efficiency and reliability make it a smart choice for maximizing production output while keeping costs manageable.

At Micmachinery, we are dedicated to supporting our clients every step of the way. Our knowledgeable team is ready to assist with installation, training, and ongoing maintenance, ensuring that your soda can filling machine operates at peak performance throughout its lifecycle.

In conclusion, the MIC Manual Soda Can Filling Machine is an essential investment for any small-scale beverage manufacturer. With its durable construction, user-friendly operation, and emphasis on hygiene, it embodies Micmachinery's professionalism and commitment to excellence in the beverage industry. Choose our innovative solutions to enhance your production capabilities and thrive in today’s competitive market.

Control Button

Control buttons can control when the machine starts filling and can stop filling manually. It also can change the counter pressure filling valves to normal pressure filling valves.then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

Filling Head

After pressing the button, the filling head enters the inside of the cans and fills the beer into the cans. Filling heads are easy to replace and clean.

| Filling Heads | 2 Pieces |

| Production Capacity | 8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure |

0.4-0.6Mpa |

|

Can Diameter Range |

Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight |

15KG |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Other Types Of Labeling Machines

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Empty Can Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Beverage Processing Equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Other Types Of Labeling Machines

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Empty Can Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Can filling machine

- Beverage Processing Equipment