- E-mail: sales8@micmachinery.com

- Mobile: 0086-13083991987

- Whatsapp: 0086-13083991987

- Wechat: 0086-13083991987

- Shipment: exporting country

- Customer reviews: click on

The machine is a kind of professional hot filling machine for orange juice, apple juice and other hot filling beverage which applies to PET bottle.

It is made of high quality SUS304 stainless steel. Main components are processed precisely by CNC machine tool. The machine adopts advanced photo electricity to detect running status. No bottle no filling. It realize man-machine conversation because of applying touch screen for operation

1) Bottle is entered by air conveyor, the speed of bottle entering is fast and bottle shape isn’t changed because of adopting hanging clamping bottleneck way

2) Adopting clamping bottleneck way to wash bottle mouth and avoid touching screw mouth, adopting clamping bottleneck way in the whole conveying process. When bottle type changes, you need to change the board related with bottle diameter

3) Filling adopts cylinder feeding structure, filling valve adopts high filling speed and mass flow rate valve which control liquids level accurately and without loss.

4) Screw capper adopts French advanced technology which cans screw cap promptly when clamping bottle.

5) The PLC and transducer are chosen from international famous brand, such as OMRON, MITSUBISHI and so on

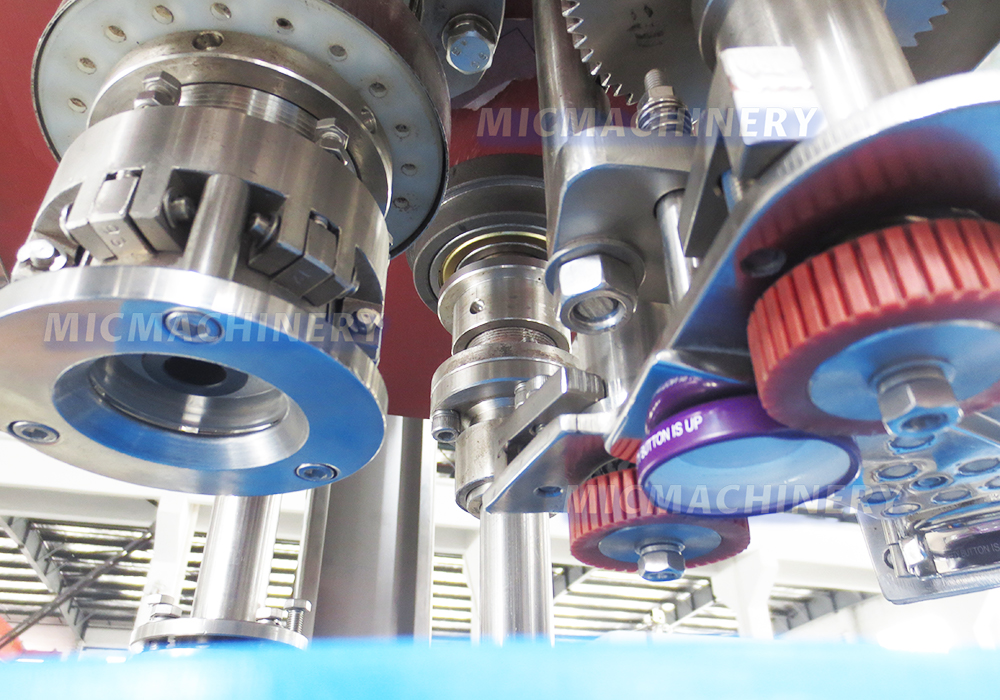

Capping Part

Capping part is mainly composed of capping heads, cap loader (separated), cap unscrambler, cap drop rail, pressure regular, cylinder and also we need an air compressor as the auxiliary external equipment.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. The capper is equipped with inlet bottle detection switch.

Filling Part

Filling part is mainly composed of filling barrel, filling valve (low temperature and isobar filling), filling pump, bottle hanging device / bottle pedestals, guide rail, elevating device, liquid indicator, pressure gauge, pressure regulator, etc.

Rotary wheel fully made of stainless steel SUS 304. Filling valves are made of SUS316L. Filling valves are reasonably structured with accurate filling. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

| Technical parameter | |

|---|---|

| Capacity | 8000-10000b/h(500ml) |

| Filling volume | 200ml-2000ml (standard filling) Can be adjusted |

| Filling material | Juice |

| Standard bottles | PET bottle, |

| Diameter of bottle: Φ50~Φ110mm | |

| Height of bottle: 150-320mm | |

| Filling: | hot filling under constant pressure |

| Filling temperature | 87+-5℃ |

| Compressed air pressure | 0.3-0.7 M pa |

| Rinsing water pressure | 0.2-0.25 M pa |

| Rinsing water | Aseptic water |

| Total power consumption | 7kw |

| Power | 380V, 50Hz, 3 phase(according to customer’s requirement) |

| Suitable cap | standard plastic cap with screw thread |

| overall dimensions | 3000x2200x2300mm |

| weight | 5500 kg |

| No. | Name | Brands | |

|---|---|---|---|

| 1 | Frequency converter | Siemens | Germany |

| 2 | PLC | Siemens | Japan |

| 3 | Touch screen | Siemens orTaiwan | Germany orTaiwan |

| 4 | Contactor | Siemens | Germany |

| 5 | Thermal relay | Siemens | Germany |

| 6 | Air switch | Schneider | France |

| 7 | Proximity switch | OMRON | Japan |

| 8 | The photoelectric switch | OMRON | Japan |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Other Types Of Labeling Machines

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Empty Can Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Beverage Processing Equipment

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

-

Labeling Machine

- Round Bottle Labeling Machine

- Other Types Of Labeling Machines

- Shrink Sleeve Labeling Machines

- Shrink Sleeve Machine Shrink Label Machine

- Shrink Sleeve Applicator Packaging Machine

- Can Sleeving Machine

- Shrink Sleeve Packaging Machines

- Hot Melt Glue Labeling Machine

- Self Adhesive Labeling Machine

- Laser Coding Machine

- Round Bottle Labeling Machine

-

Packing Machine

- Wrap Packing Machine

- Case Packing Machine

- Blow-drying Machine

- Empty Can Depalletizer

- Carbonated Drink Mixing Machine

- Pasteurization Machine

- Liquid Nitrogen Dosing Machine

- X-Ray Liquid Level Detection Machine

- Weight Detector

- Metal Detector Food Industry

- Aseptic Liquid Nitrogen Dosing Machine

- Palletizer

- Pallet Wrapping Machine

- Bottle Blowing Machine

- Semi Auto Bottle Blowing Machine

- Wrap Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Water Filling Machine

- Aseptic Cold Filling Machine

- Can filling machine

- Beverage Processing Equipment