- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

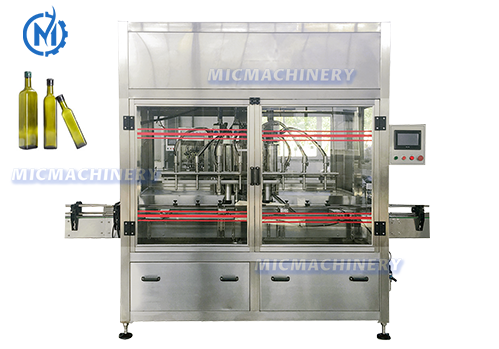

This piston filling machine is suitable for:

beverage, soft drink, csd drink, olive oil, sunflower oil, bean oil, seasam-seed oil, vegetables oil, edible oil, peanut oil, palm oil, corn oil, sauce and other similar products.

This machine function is:

1. Automatic bottle sensing system and filling

2. No bottle no filling

3. Filling error is control within 1‰

4. Filling arrange : mini volume: max volume =1:10

5. Automatic filling volume correction system.

6. Can be customized for different bottle and caps.

7. Can be equipped with cleaning system.

This machine filling system is made for cosmetics package food bottle medical products and chemical products, easy clean and changes, we have automatic piston opening for cleaning. it is a practical machine for production and clean, 24 hours runs none stops, hardly have machine break down once well adjusted.

Machine filling accuracy max is at 1%, from 100ML-1000ML, 1L-5L volume, and it is piston filling controlled by servo motor.

This machine is mechanical transmission, controlled by servo motor, it is well developed machine, use life more than 15 years.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

Soft drink filling machines are used in a variety of settings, including bottling plants, beverage production facilities, and even small-scale operations such as restaurants or cafes. They are essential for ensuring that beverages are filled to the correct level and in a consistent manner, which is important for maintaining quality and meeting regulatory standards.

Overall, soft drink filling machines are a key component of the beverage production process, enabling manufacturers to produce large quantities of high-quality drinks efficiently and effectively.

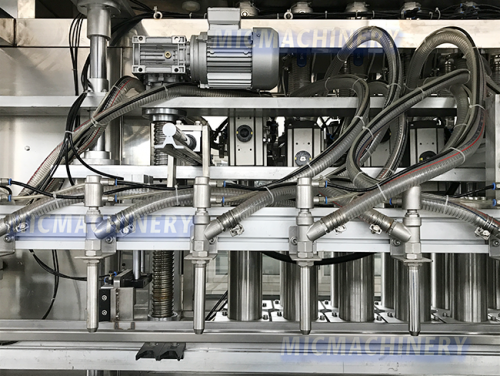

Filling head

Put the oil into the material cylinder, the three-way valve controls the piston to pump oil into the metering cylinder cylinder, then the piston moves up to send the oil to the filling pipe, and when the bottle enters the filling machine through the conveyor belt, the filling head moves down to fill.

This filling machine has eight filling heads (the number of filling heads can be customized to your needs)

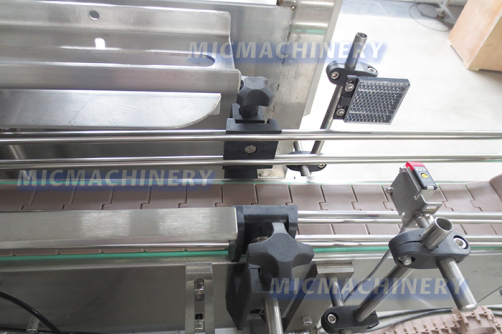

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time

The conveyor belt can be different sizes of bottles, beside the width between the two tubes can be adjust according to your packaging container, ensure smooth bottle safely from the conveyor belt moved.The sides of the conveyor belt are equipped with sensors that are automatically identified when the bottle comes or goes out to send a signal to the filling and screwed cover station.

Thank you for the reading this article,

you can also check video for:

|

Filling Head |

8 Heads |

|

Filling Volume Range |

50-1000ml(Use 1000ml Piston Cylinder) |

|

Production Speed |

≤1800 Bph basis on 1000ml bottle |

|

Voltage |

220v/380v |

|

Power |

3kw |

|

Suitable Bottle’s Diameter |

Ф40mm-Ф100mm |

|

Filling Error |

≤±1 |

|

Work Pressure |

0.55Mpa-0.65Mpa |

|

Size |

2000mm × 1400mm× 2500mm |

|

Weight |

1000kg |

|

Parts |

Brand |

|

Touch Screen |

Canada xinjie color |

|

PLC |

Schneider |

|

Solenoid Valve |

Taiwan Airtac |

|

Optoelectronic System |

OPTEX |

|

Micro Differential Pressure Switch |

Netherlands |

|

Servo Motor |

Taiwan TECO |

|

Air Source Treatment |

Taiwan Airtac |

|

Button and low voltage electric appliance |

Schneider |

|

Ball Screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching Power Supply |

Taiwan Meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine