MIC Fully Automatic Juice Packaging Machine(10-50BPM)

- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

1. The juice packaging machine incorporates a frequency conversion speed regulation device, allowing users to adjust the speed within a specified range as needed.

2. It features an automatic detection function that prevents feeding and heat sealing if the bag is not opened or opened incompletely. This feature minimizes material waste, saves production costs, and allows for the reuse of bags.

3. A safety device is installed to alert users in case of abnormal working air pressure or heating pipe failure.

4. Operators are protected by a plexiglass safety door that ensures their safety during operation.

5. To maintain a clean production environment, the machine utilizes an oil-free vacuum pump, preventing pollution.

Additional Points:

* The bag width can be easily adjusted with a single button.

* The machine complies with GMP requirements, ensuring environmental protection and a pollution-free process.

* All contact parts are constructed using 304/316 stainless steel, ensuring hygienic and safe operation.

2. It features an automatic detection function that prevents feeding and heat sealing if the bag is not opened or opened incompletely. This feature minimizes material waste, saves production costs, and allows for the reuse of bags.

3. A safety device is installed to alert users in case of abnormal working air pressure or heating pipe failure.

4. Operators are protected by a plexiglass safety door that ensures their safety during operation.

5. To maintain a clean production environment, the machine utilizes an oil-free vacuum pump, preventing pollution.

Additional Points:

* The bag width can be easily adjusted with a single button.

* The machine complies with GMP requirements, ensuring environmental protection and a pollution-free process.

* All contact parts are constructed using 304/316 stainless steel, ensuring hygienic and safe operation.

The juice packaging machine represents a significant technological advancement in beverage manufacturing, providing a streamlined and automated solution for efficiently packaging juices. With meticulous engineering and cutting-edge design, this state-of-the-art equipment seamlessly integrates various components to create a highly efficient packaging line. By combining speed, accuracy, and reliability, the juice packaging machine plays a crucial role in meeting the evolving demands of juice manufacturers.

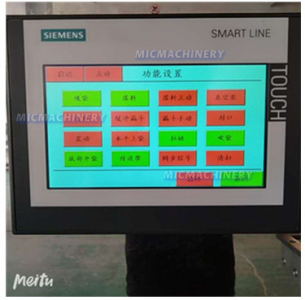

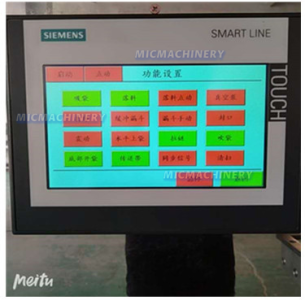

Control Panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

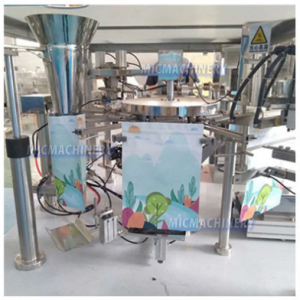

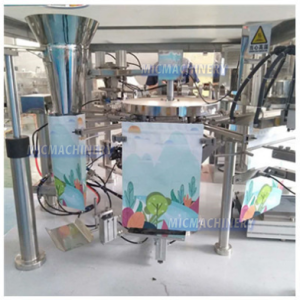

Automatic bag opening device

Its main function is to open the bag and prepare the filling materialMain work flow: suction cup will bring the bag to the main rotary plate, the main rotary plate holds the bag into the vacuum bag opening station. The bag is vacuumed by suction cups and assists in blowing air out. After the bag is opened, the filling begins, then the bag is sealed, and the final product is conveyed out of the filling machine through a conveyor belt

|

Bag material |

Compound mold |

||

|

Bag type |

Zipper free standing |

||

|

Bag size |

W: 100-210mm L: 100-350mm |

W:150-260mm L:150-350mm |

W200-300mm L:200-450mm |

|

Speed |

10-50bag/min |

10-40bag/min |

10-40bag/min |

|

Weight |

1200KG |

1400KG |

1500KG |

|

Voltage |

380V 3 Phase 50HZ/60HZ |

||

|

power |

3KW |

4KW |

4KW |

|

Compressed air |

0.6m ³ /min |

||

Products

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

Product Catalog

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine