- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

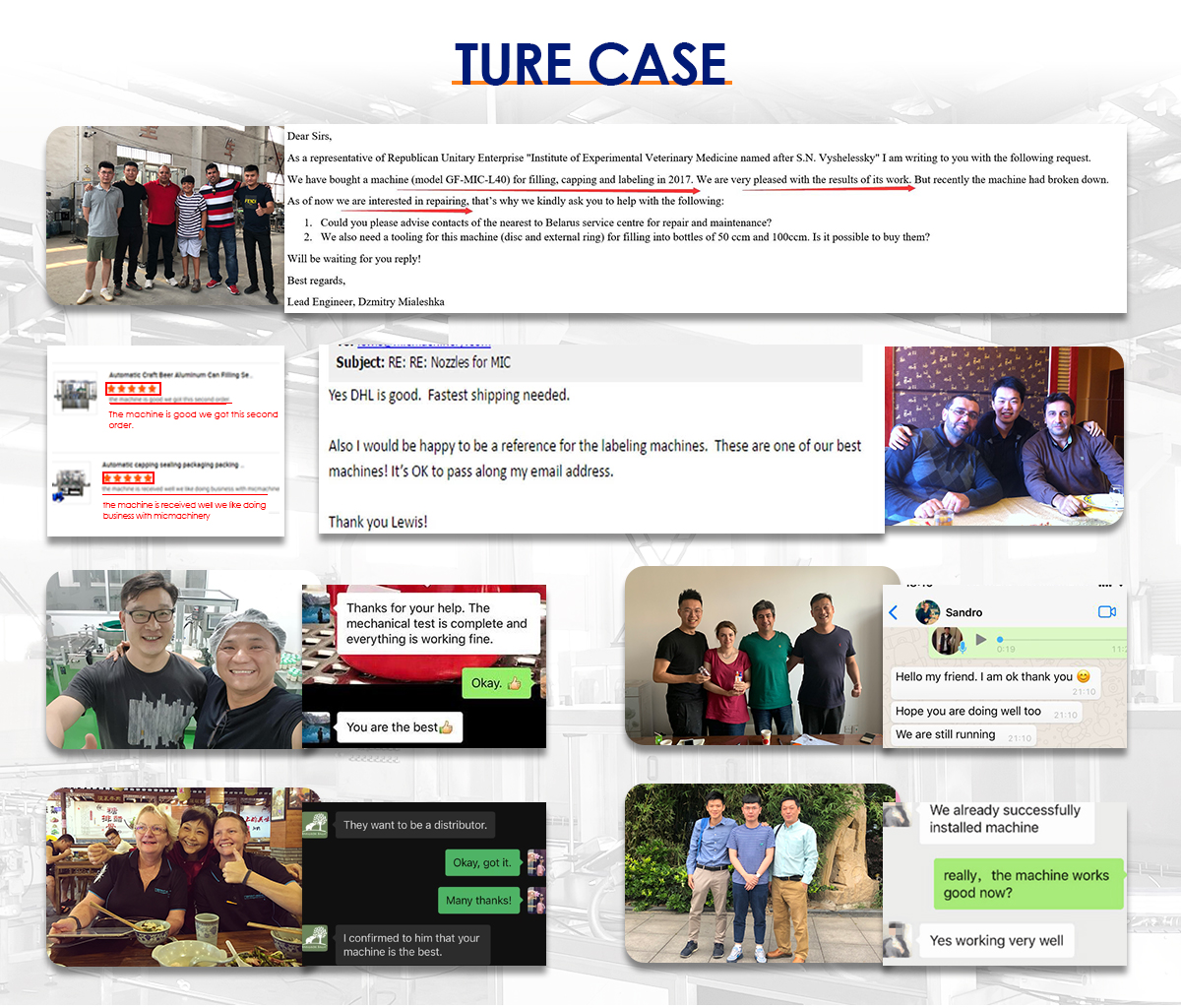

- Customer reviews: click on

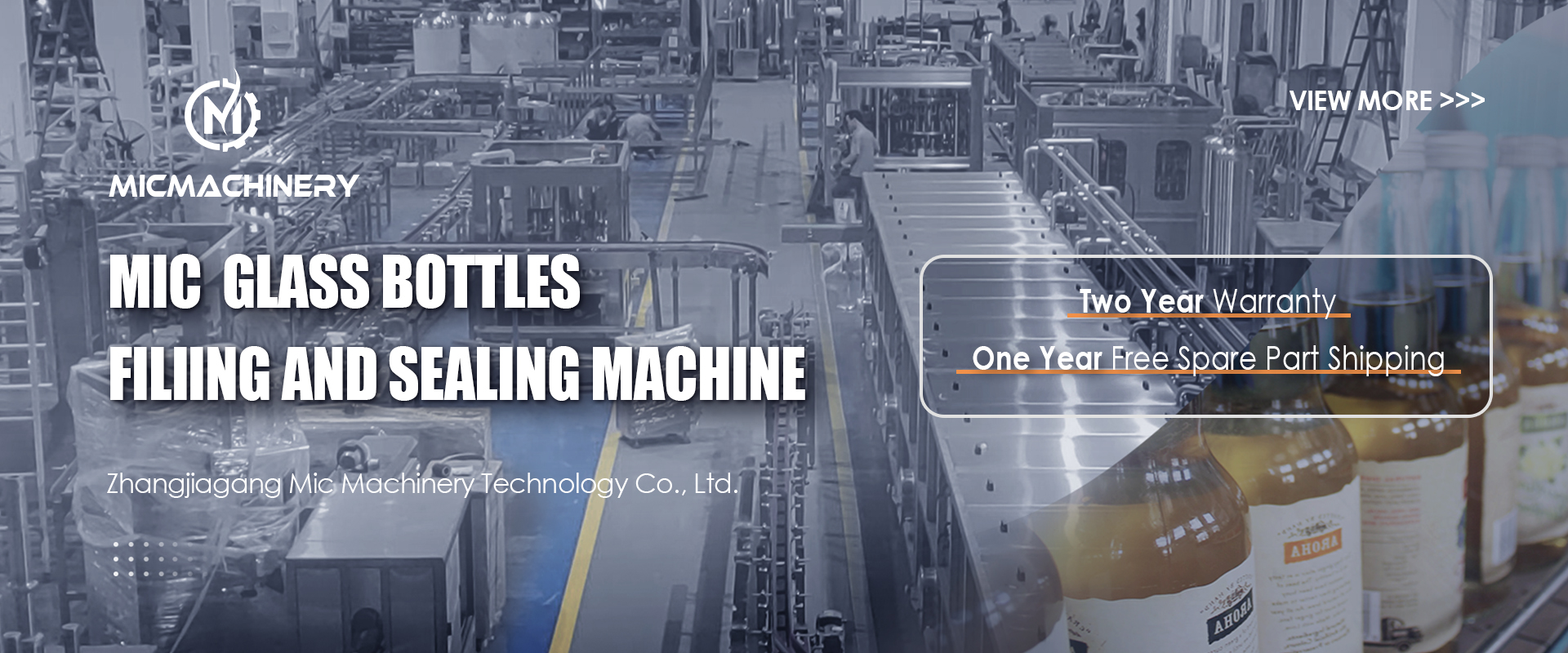

MIC 24-24-8 Small Beer Bottling Line is applicable for glass bottle filling capping machine for craft Beer

Machine working principle:

1. Isobaric pressure filling, controled by pressure, accuracy is +/-1%,liquid level difference is not more than 4-5mm(cause bottle has difference when it produced). easy adjustmeant on liquid level.

2. Glass bottle capping machine is qualified for Chinese capping standard, and no air leakage at all, machine capping rate is 99.5%.

3. Aluminum cap and crown cap are ok problem working on our capping machine(different capping head), We use our own technical drawing and own processing machine, to make sure our capping head quality and always easy to purchase.

4. If bottle stock on conveyor sensor will inform PLC to stop at the feeding part.

5. About machine automation, we are able to do what client required.

6. About machine test and shipment, we are stick with real production test till all problem is fix and then ship out.

7. Consider of product various ability, we are able to make machine for replace air from the can package.

A typical beer bottling line consists of several machines and conveyors that work together to fill, cap, label, and package beer bottles. The process starts with empty bottles being loaded onto the conveyor belt, which then moves them through a series of stations designed to clean and sanitize the bottles.

Next, the bottles are filled with beer using a specialized filling machine that dispenses the correct amount of beer into each bottle. The filled bottles are then moved through a capping station, where caps are applied to each bottle to ensure a tight seal.

After capping, the bottles are typically moved through a labeling station, where labels are applied to each bottle. The labels often include information such as the beer brand, alcohol content, and ingredients. Finally, the bottles are packaged in cases or cartons and are ready for distribution.

A beer bottling line is an essential piece of equipment for breweries and bottling plants, as it allows for faster and more efficient packaging of beer. It also ensures that the beer is packaged in a consistent manner, which is important for maintaining the quality and taste of the beer.

Whether you are a small craft brewery or a large commercial operation, investing in a high-quality beer bottling line can help to streamline your operations and improve your bottom line. By automating the bottling process, you can increase your production capacity, reduce labor costs, and improve the overall quality of your beer.

For this production line you might be interested in:

Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine.

beer bottling equipment, beer bottle filling machine, beer filling line, small beer bottling line, automatic beer filling machine, beer bottle filling equipment, beer filling equipment, bottling machine beer, automatic beer bottling machine, beer bottle filler, beer filling machine

Lately news for shipment:

Washing And Filling Part

The bottle is turned upside down and centered above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again.

Rotary wheel fully made of stainless steel SUS 304. Filling valves are made of SUS316L. Filling valves are reasonably structured with accurate filling. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Capping Part

Capping part is mainly composed of capping heads, cap loader (separated), cap unscrambler, cap drop rail, pressure regular, cylinder and also we need an air compressor as the auxiliary external equipment.Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. The capper is equipped with inlet bottle detection switch.

Bottle Shrink Sleeve Machine

A bottle shrink sleeve machine is an advanced packaging equipment designed for the labeling and packaging of bottles. It is a high-speed machine that applies heat-shrinkable sleeves onto bottles, creating a tamper-evident and aesthetically pleasing label that conforms to the shape of the container. This machine is commonly used in the food and beverage industry for labeling bottles of various shapes and sizes, including water bottles, juice bottles, beer bottles, and more.

Carton Case Packer

The grabbing type case packer is reliable in operation: This machine is realized by the servo to pick up and release the product. Through the mechanical operation, pneumatic and electric control, the product can be accurately and reliably picked up from the box holder with a suction cup into the carton.

| Model | MIC-24-24-8 |

|---|---|

| Washing heads | 24pcs |

| Filling heads | 24pcs |

| Capping heads | 8pcs |

| Volume | 0.1-1L |

| Production capacity | 2000-6000bottle/hr base on 330ml |

| Filling method | Isobaric (once vacuum) |

| Power | 1.5kw 380V/50HZ(According to customer) |

| Air pressure | 0.7Mpa |

| Gas consumption | 0.8m³/min |

| Water consumption for bottle washing | 1.5-2T/H |

| Wash bottle water pressure | 0.2~0.25 Mpa |

| Weight | 4500kg |

| Dimension | 2500×1400×2500mm |

| Electrical configuration | ||

|---|---|---|

| Touch screen | MITSUBISHI | |

|

Frequency converter | MITSUBISHI |

| PLC | MITSUBISHI | |

| Contactor, breaker | DELIXI | |

| Proximity switch | DELIXI | |

| Photoelectric switch | DELIXI | |

| Relay | OMRON | |

| Barometer | AirTAC | |

| Air cylinder | AirTAC | |

| Solenoid valve | AirTAC | |

| Bearing | Harbin | |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine