- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

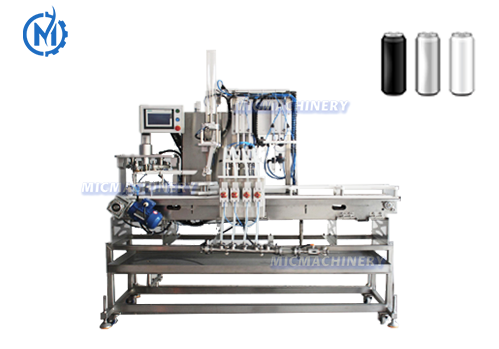

Automatic mobile portable small beer canning machine is very suitable for small brewery. It has Co2 purge function, counter pressure filling system, lid loading system, lid seaming system, cover cleaning function.

Business items

1)Price is on the basis of FOB Shanghai

2)Payment term: 30% T/T deposit advanced, 70% T/T balance before shipment.

3)Delivery time: 45-50 working days after receiving samples and deposit

4)After-sale service: We provide one year guarantee, provide timely and effective services.

After the warranty period, we provide users with lifetime technical service and after-sales service.

5)PRICE VALID TIME: 60DAYS

If you're looking for a reliable and efficient way to fill beer cans at a rate of 1000-1500 cans per hour, look no further than Micmachinery. Our linear beer can filling equipment is perfect for small to medium-sized breweries looking to streamline their canning process.

Our equipment features advanced technology that ensures precise and consistent fills, ensuring that your beer maintains its quality and flavor profile. The linear design of our equipment also makes it ideal for breweries with limited space, as it takes up less room than traditional rotary can fillers.

At Micmachinery, we pride ourselves on providing high-quality equipment that is built to last. Our linear beer can filling equipment is made with durable materials and is designed to withstand the demands of high-volume production.

Our team of experts is also dedicated to providing exceptional customer service and support. We'll work with you to customize your equipment to meet your specific needs and provide ongoing technical support to ensure that your equipment runs smoothly.

Don't let inefficient filling equipment slow down your brewery's growth. Contact Micmachinery today to learn more about how our linear beer can filling equipment can help you increase production and efficiency.

Linear Beer Can Filling Machine

This linear beer can filling machine has four filling heads, when the beer can enter into the machine, automatically filling. Then beer can enter capping station.

Filling Head

After pressing the button, the filling head enters the inside of the cans and fills the beer into the cans. Filling heads are easy to replace and clean.

Coveryor Station

The conveyor belt transports the bottles into the filling and capping system. When the machine fails, the conveyor belt will automatically stop working

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine