Machine Usage

1. Intuitive Controls:

Featuring an easy-to-use interface, the machine's controls are designed with simplicity in mind. This ensures that operators can efficiently manage the filling process without extensive training, contributing to a seamless production experience.

2. Adaptability to Bottle Varieties:

The machine's usage extends to a variety of bottle sizes and shapes. Whether you are bottling standard-sized soda water or experimenting with unique packaging, our machine adapts effortlessly to your requirements.

Machine Application

1. Soft Drink Bottling Excellence:

Our automatic soda water filling machine specializes in soft drink bottling, ensuring that every bottle is filled with precision and care. Whether you are producing classic sodas, flavored beverages, or soda water, our machine is engineered to meet diverse soft drink bottling needs.

2. Efficiency for Various Formulations:

The machine's application versatility extends to handling various formulations. Whether your soft drink recipe involves natural flavors, carbonation levels, or specific ingredients, our machine caters to the nuanced requirements of different beverage formulations.

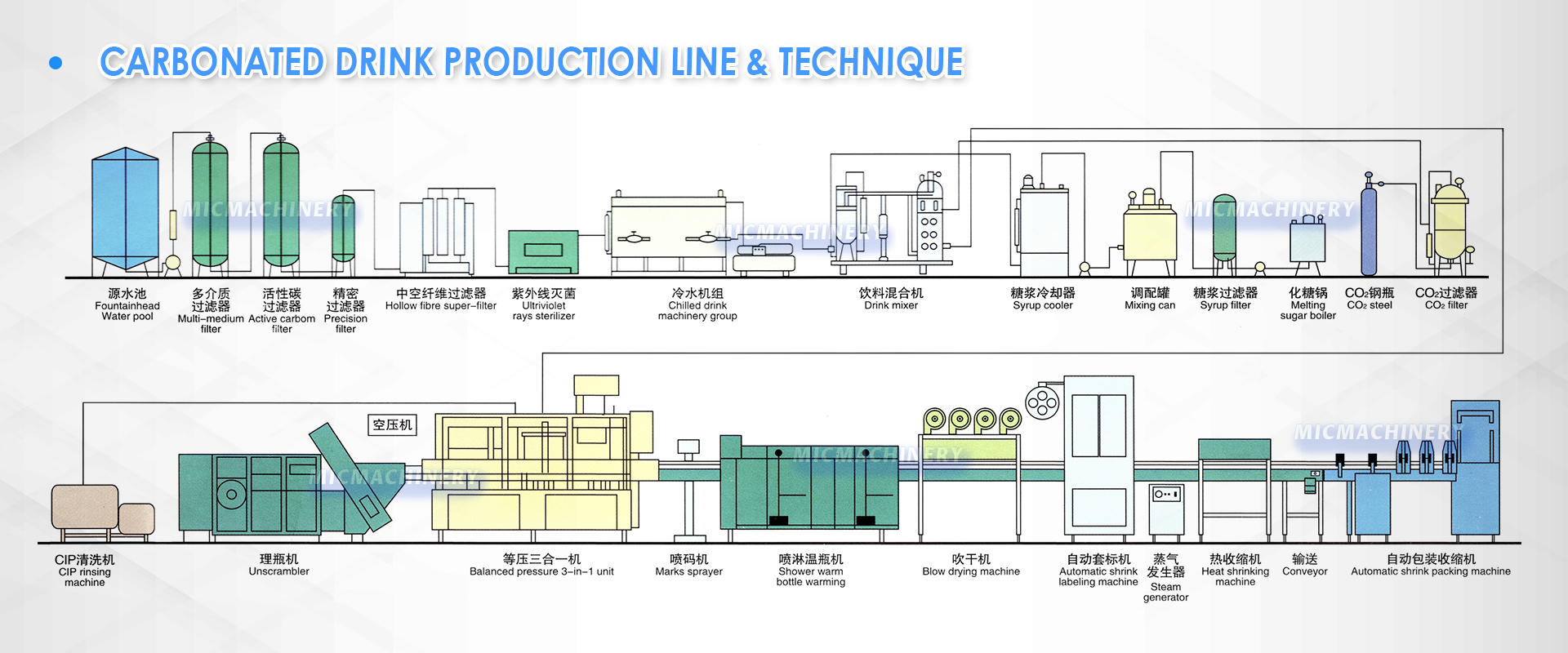

Machine Workflow

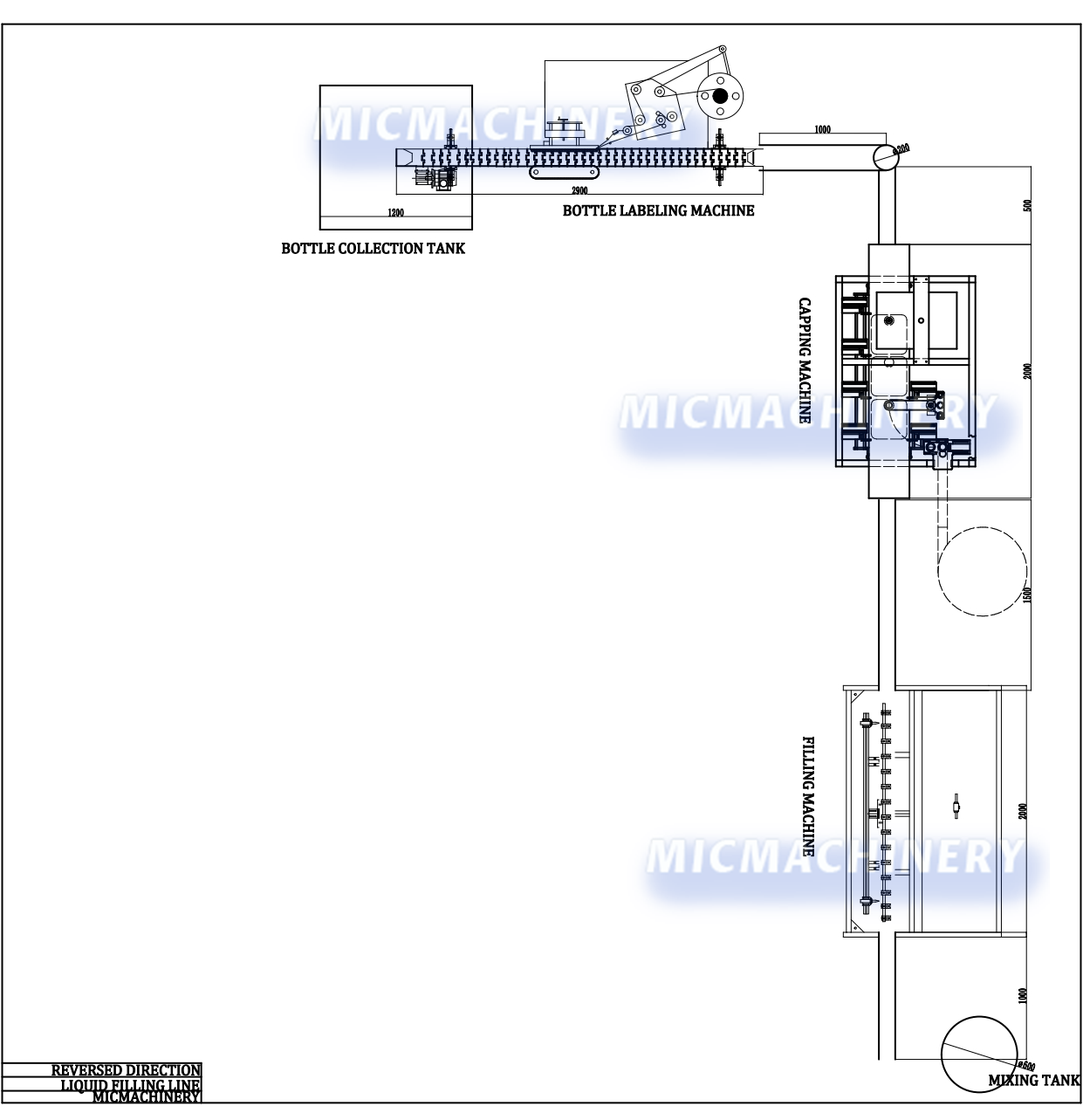

1. Bottle Feeding:

The workflow begins with the efficient feeding of bottles into the system, preparing them for the soda water filling process.

2. CO2 Infusion and Carbonation:

Our machine meticulously controls the infusion of CO2 gas, ensuring precise carbonation levels for each bottle. This step is critical in achieving the desired effervescence in every soft drink.

3. Automatic Filling Mechanism:

The heart of our machine lies in its automated filling mechanism. This feature guarantees accurate and consistent fills, minimizing variations and optimizing production efficiency.

4. Capping Excellence:

Integrated seamlessly into the workflow, our machine's capping mechanism ensures a secure seal for each bottle, preserving the carbonation levels and overall quality of the soft drink.

Speed: 1000-2000CPH

Speed: 4000-8000CPH

Speed: 1000-1500CPH

Speed: 1500-2500CPH

Speed: 6000-10000CPH

Speed: 480CPH

Speed: 3000-6000CPH

Speed: 8000-15000CPH

Speed: 1800CPH

Speed: 800-1500BPH

Speed: 2000-3000BPH

Speed: 200-800BPH

Speed: 800-1500BPH

Speed: 8000-10000BPH

Speed: 3000-5000BPH

Speed: 14000BPH

Advanced Features of Our Automatic Soda Water Filling Machine:

1. Automated Precision:

At the core of our machine lies an automated filling mechanism that guarantees precision in every fill. This advanced technology ensures accurate fill levels, minimizing variations and optimizing the overall efficiency of your soft drink bottling process.

2. Adaptable to Soft Drink Varieties:

Our automatic soda water filling machine is designed for versatility. Whether you are bottling classic sodas, flavored beverages, or soda water, our machine adapts seamlessly to the nuanced requirements of different soft drink formulations.

Machine Workflow Excellence:

1. Efficient Bottle Feeding:

The workflow begins with the efficient feeding of bottles into the system, setting the stage for the soda water filling process.

2. CO2 Infusion and Carbonation Control:

Our machine meticulously controls the infusion of CO2 gas, ensuring precise carbonation levels for each bottle. This step is crucial in achieving the desired effervescence in every soft drink.

3. Automated Filling Mechanism:

The heart of our machine lies in its automated filling mechanism. This feature ensures that each bottle is filled accurately and consistently, maintaining the quality and taste of your soft drink.

4. Capping Excellence:

Integrated seamlessly into the workflow, our machine's capping mechanism ensures a secure seal for each bottle. This not only preserves the carbonation levels but also contributes to the overall quality and freshness of the soft drink.

Advantages of Choosing Mic Machinery:

1. Precision Engineering:

Our automatic soda water filling machine is a testament to precision engineering, ensuring that every bottle leaving the production line meets the highest standards of quality.

2. Versatility for Soft Drink Producers:

Whether you are a seasoned soft drink producer or an emerging player in the industry, our machine caters to your diverse production needs, providing adaptability and efficiency in soft drink bottling.

Conclusion:

In conclusion, Mic Machinery is committed to advancing soft drink bottling technology with our automatic soda water filling machine. Experience the efficiency, precision, and adaptability that set our machine apart. Whether you are producing classic sodas or experimenting with innovative formulations, our solution is designed to meet your production goals with excellence. Explore the possibilities of precision crafting with Mic Machinery.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine