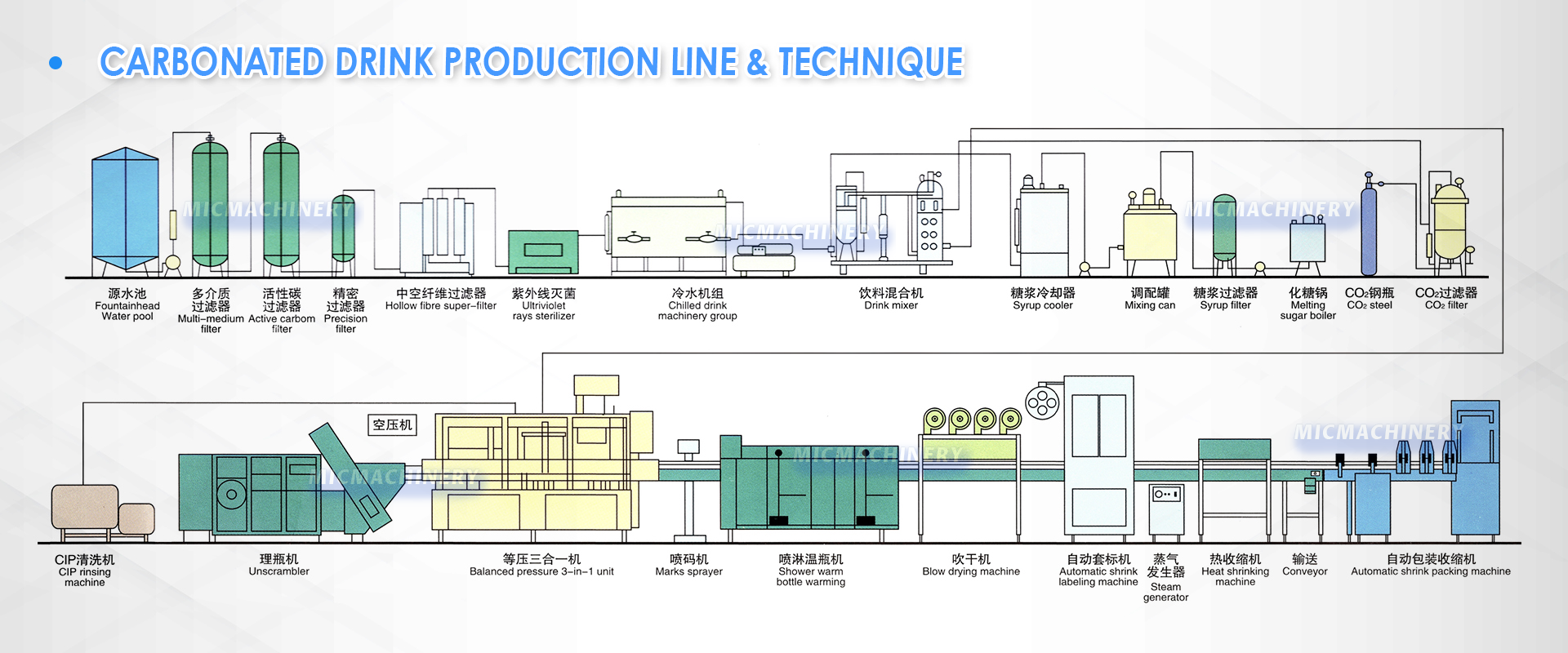

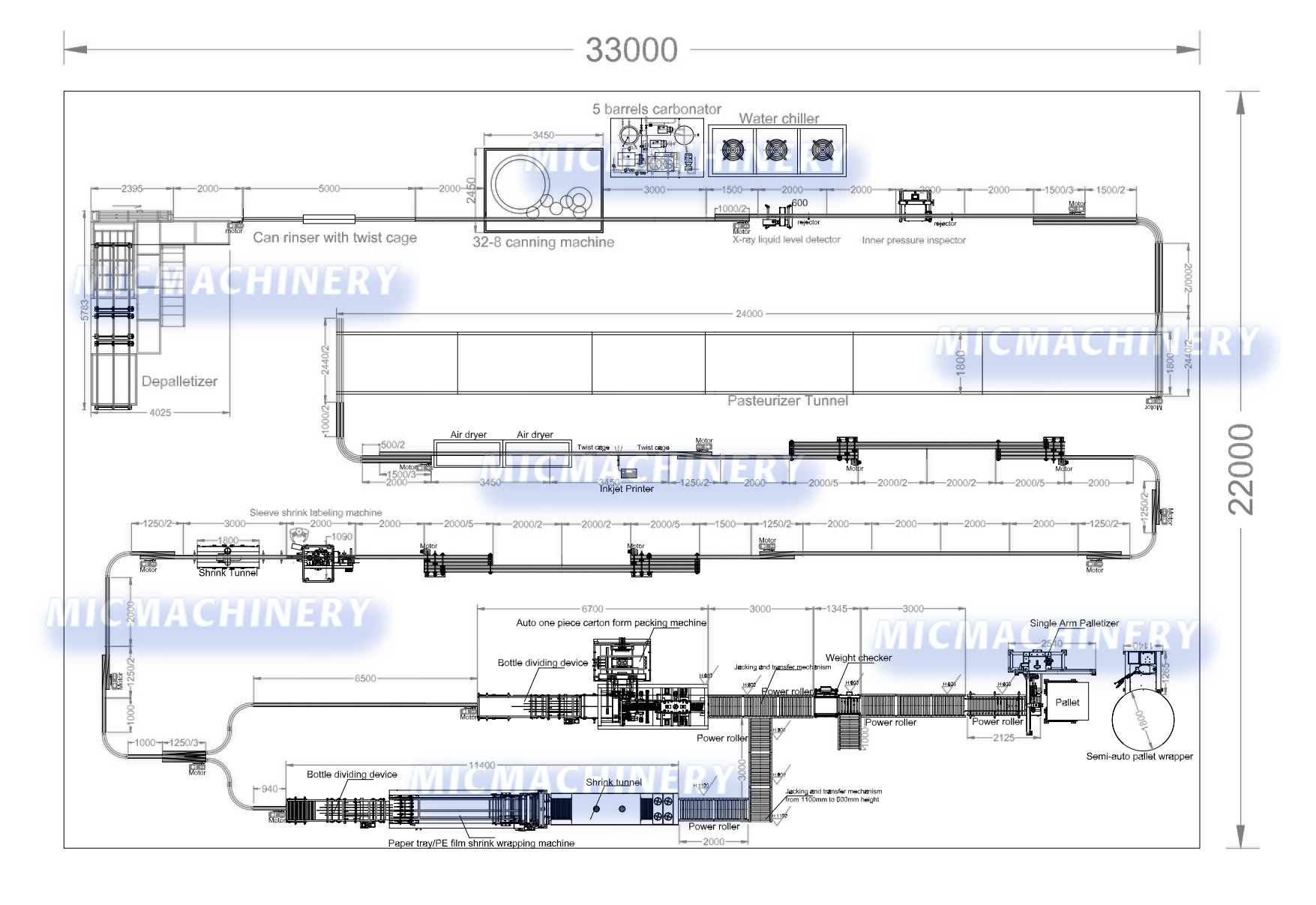

Machine Function

1. Can Fabrication:

The journey begins with the fabrication of top-quality aluminum cans. Crafted with precision, these cans serve as the foundation for a reliable and robust packaging solution.

2. Filling Station Excellence:

The heart of our soda can production line lies in the filling station. Here, our advanced machinery takes center stage, executing a precise fill of carbonated beverages into each can. This function ensures uniform quality and carbonation levels, contributing to an exceptional consumer experience.

3. Seaming and Lid Application Expertise:

Post-filling, cans transition effortlessly to the seaming and lid application stage. Our cutting-edge system guarantees a secure and hermetic seal, preserving the freshness and effervescence of the beverages within.

4. Quality Control Assurance:

Integrated quality control measures at every stage reinforce our commitment to excellence. Only cans meeting stringent standards advance through the soda production line, guaranteeing a final product of unparalleled quality.

5. Optimized Packaging Process:

Successfully validated cans move seamlessly to the packaging station, where efficiency is optimized. This ensures that the end products are not only of superior quality but are also packaged with precision for seamless distribution.

Machine Application

1. Carbonated Drink Production:

Tailored explicitly for carbonated beverages, our carbonated drink production line accommodates a wide range of formulations, ensuring a perfect fill for each can.

2. Sparkling Water and Seltzers:

The soda production line effortlessly adapts to the production of sparkling water and seltzers, meeting the growing consumer demand for refreshing alternatives.

3. Crafted Brews and Considerations like Beer Canning Line Cost:

Breweries and craft beverage producers benefit from the adaptability of our line, with a keen eye on economic considerations such as the beer canning line cost. We offer cost-effective solutions without compromising on the efficiency of the canning process.

Machine Advantages

1. Cost-Effective Solutions:

Emphasizing economic viability, our solutions, including considerations like the beer canning line cost, ensure that breweries and beverage manufacturers benefit from a cost-effective yet high-quality canning process.

2. Operational Precision:

The precision-driven operations of our soda production line guarantee a consistent and reliable canning process. From fabrication to packaging, operational efficiency is our hallmark.

3. Flexibility and Adaptability:

The adaptability of our carbonated drink production line allows for the production of various beverages, making it a versatile choice for manufacturers seeking flexibility in their product offerings.

Speed: 1000-2000CPH

Speed: 4000-8000CPH

Speed: 1000-1500CPH

Speed: 1500-2500CPH

Speed: 6000-10000CPH

Speed: 480CPH

Speed: 3000-6000CPH

Speed: 8000-15000CPH

Speed: 1800CPH

Soda Can Production Line: A Symphony of Precision and Efficiency

1. Can Fabrication:

2. Filling Station:

3. Seaming and Lid Application:

4. Quality Control Measures:

5. Packaging and Distribution:

Carbonated Drink Production Line: Meeting Diverse Market Demands

1. Sparkling Water and Seltzers:

2. Crafted Brews and Beer Canning Line Cost:

In conclusion, at Mic Machinery, our commitment to innovation is not just a promise; it's a reality reflected in our advanced soda can production line and versatile carbonated drink production line. Join us as we redefine industry standards, delivering precision and reliability in every can produced. Explore the future of beverage packaging with Mic Machinery, where every can tells a story of innovation and excellence.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine