Product Application

1. Versatile Bottled Water Offerings:

Water bottling lines stand as pillars of versatility in bottled water offerings. Whether it's still water, sparkling water, or enhanced mineral water, these lines adapt seamlessly to a spectrum of products. The versatility in product application positions them as essential components for businesses aiming to diversify their bottled water product portfolio.

2. Precision in Filling and Capping for Different Sizes:

Beyond standard applications, water bottling lines showcase precision in filling and capping for bottles of different sizes. This characteristic is pivotal for businesses catering to varying consumer preferences and packaging requirements. The adaptability in size ensures that each bottle, regardless of dimensions, is filled and capped with meticulous accuracy.

3. Streamlined Production for Efficient Market Entry:

Water bottling lines facilitate streamlined production, serving as a gateway for efficient market entry. Whether it's for startups exploring a water bottling venture or established businesses expanding their beverage offerings, these lines offer a cohesive solution. The streamlined production process ensures market-ready products with minimal lead time.

Product Characteristics

1. Hygienic Stainless-Steel Construction:

A defining characteristic is the use of hygienic stainless-steel construction. This feature not only ensures the purity of the water but also enhances the durability and cleanliness of the equipment. The commitment to maintaining the highest standards of hygiene aligns with the expectations of consumers in the bottled water market.

2. Automated Filling and Capping Mechanisms:

Water bottling lines feature automated filling and capping mechanisms, exemplifying technological advancement. The automated nature of these systems ensures precision in every stage, from liquid filling to secure capping. This characteristic not only contributes to the quality of the end product but also minimizes the margin for error in the production process.

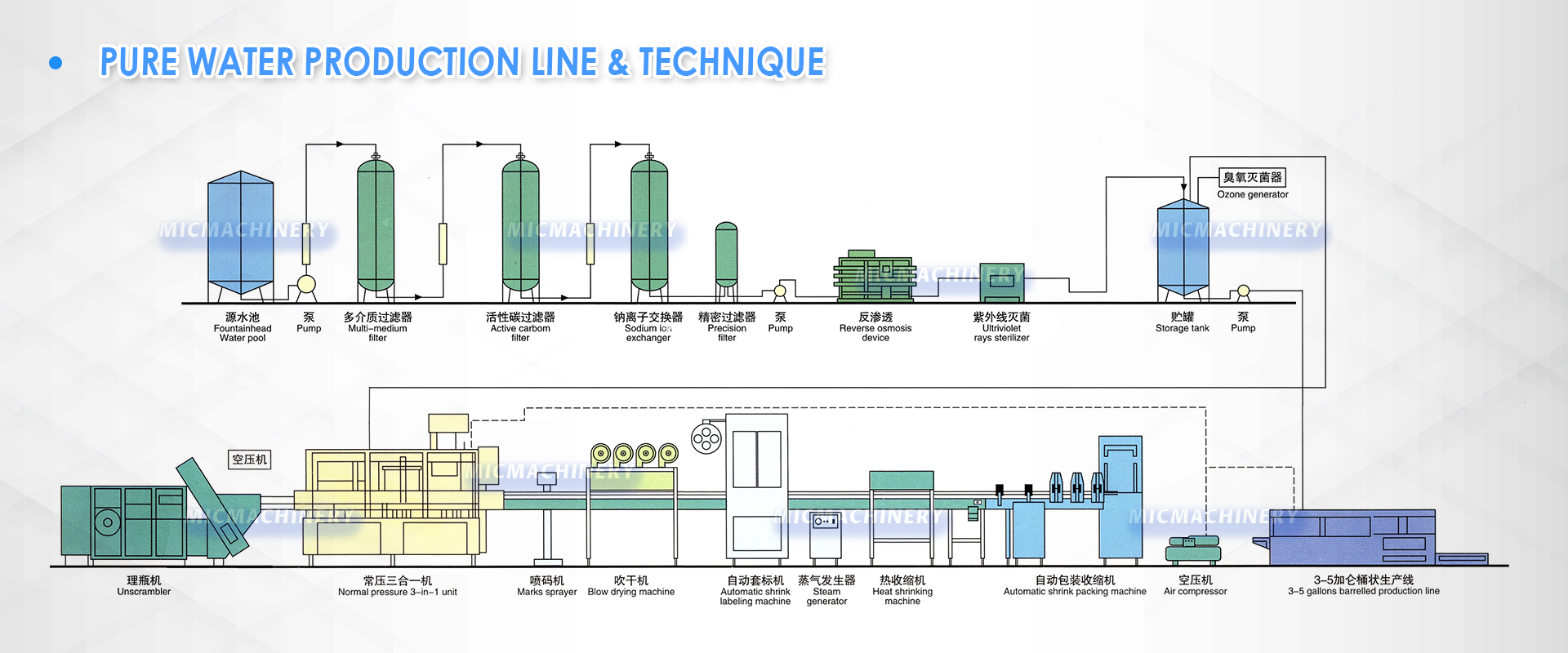

3. Innovative Filtration Systems:

The inclusion of innovative filtration systems is another key product characteristic. These systems emphasize the importance of purity in bottled water by eliminating impurities and contaminants. The advanced filtration ensures that the water reaching consumers is of the highest quality, meeting the discerning standards of modern consumers.

Machine Parameter

1. Variable Production Capacities:

A critical machine parameter of water bottling lines is the ability to accommodate variable production capacities. Whether it's a high-volume production run or a smaller-scale operation, the machine parameters can be adjusted to align with specific production needs. This adaptability ensures efficiency without compromising quality.

2. Adjustable Filling and Capping Speeds:

The flexibility of water bottling lines extends to adjustable filling and capping speeds. Businesses can customize the speed of these processes based on bottle sizes, product variations, and overall production goals. This parameter allows for optimization, ensuring efficient operations without compromising quality.

3. Cost-Effective Water Bottle Filling Machine Price:

A crucial parameter for businesses is the cost-effectiveness of water bottling lines. The machine parameters are finely tuned to offer effective solutions without burdening budgets. The affordability, reflected in the "water bottle filling machine price," ensures that businesses of varying scales can invest in advanced bottling technology.

Speed: 5000-12000CPH

Speed: 14000CPH

Speed: 12000CPH

Speed: 200-800BPH

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

Water Bottling Line:

At Mic Machinery, we redefine the water bottling experience with our advanced water bottling line. This comprehensive solution seamlessly integrates each stage of the production process, from water purification and treatment to precise filling, capping, labeling, and packaging. Engineered for adaptability, our water bottling line is suitable for various scales of production, providing efficiency and reliability for both large-scale enterprises and small-scale operations.

Water Bottle Filling Machine Price:

In our commitment to transparency and accessibility, we offer competitive water bottle filling machine prices. We understand the importance of cost-effectiveness in today's market, and our pricing structure reflects our dedication to providing affordable solutions without compromising on quality. Explore the perfect balance between cutting-edge technology and affordability with Mic Machinery's water bottle filling machines.

Water Bottle Filling and Capping Machine:

Elevate your production efficiency with our specialized water bottle filling and capping machine. This innovative equipment streamlines the process from precise filling to secure capping, ensuring the integrity of your bottled water. Minimize manual intervention and maximize output quality with a machine designed for accuracy and reliability, setting new industry standards.

Key Features of Mic Machinery's Water Bottling Line:

1. Versatility and Scalability:

Our water bottling line caters to both large-scale enterprises and small-scale businesses, offering adaptability to various production needs.

2. Precision Filling and Capping:

Whether it's our water bottle filling machine or our specialized capping machines, precision is at the forefront of our design, ensuring consistently high-quality output.

3. Advanced Filtration Systems:

Ensure the purity of your bottled water with our equipment, featuring advanced filtration systems adhering to the highest industry standards.

4. User-Friendly Interface:

Intuitive controls and a user-friendly interface make our machines easy to operate, reducing the learning curve and minimizing downtime.

Why Choose Mic Machinery:

1. Innovation and Technology:

Stay ahead of industry trends with Mic Machinery, where our commitment to innovation ensures that your operations remain cutting-edge.

2. Quality Assurance:

Our equipment is engineered with precision and reliability in mind, guaranteeing that your water bottling operations consistently meet and exceed industry quality standards.

3. Transparent Pricing:

Mic Machinery offers competitive and transparent pricing, making advanced technology accessible without compromising your budget.

Elevate your water bottling operations with Mic Machinery's cutting-edge solutions. Explore our range, experience unmatched quality, and position your brand as a leader in the dynamic water bottling industry.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine