Product Usage

1. Beverage Can Filling Machine:

• Tailored for canning operations, the Beverage Can Filling Machine is engineered to seamlessly handle the unique requirements of filling and sealing beverage cans.

• Ideal for carbonated drinks, juices, and various non-carbonated beverages, this machine ensures precision in liquid levels and a secure, tamper-evident seal.

2. Beverage Bottle Filling Machine:

• Versatility defines the Beverage Bottle Filling Machine, catering to a diverse range of beverage packaging needs, including still water, flavored drinks, and carbonated beverages.

• This machine excels in delivering accurate filling volumes, maintaining the quality and consistency of products bottled in various sizes and materials.

Machine Characteristics

1. Automated Efficiency:

• These machines are characterized by their fully automated operations, reducing the reliance on manual labor and significantly enhancing the speed and efficiency of the beverage filling process.

• Automated systems cover filling, capping, and even labeling, ensuring a streamlined and error-free production line.

2. Precision and Consistency:

• A hallmark of automatic filling machines is their ability to achieve unparalleled precision in liquid filling. This characteristic ensures that each beverage can or bottle leaving the production line adheres to strict quality standards.

• Consistent filling levels and secure sealing mechanisms contribute to a uniform product that meets consumer expectations.

3. Adaptable Configurations:

• These machines are designed with adaptability in mind, allowing for customizable configurations to suit the specific needs of beverage manufacturers.

• Adjustments for different bottle or can sizes, materials, and production capacities provide flexibility for businesses of various scales.

Mechanical Classification

1. Gravity Filling Systems:

• Automatic Beverage Filling Machines often utilize gravity-based filling systems, allowing for precise liquid levels by leveraging the force of gravity to guide the liquid into cans or bottles.

• This mechanical classification ensures accuracy and consistency in the filling process, minimizing wastage.

2. Pressure Filling Mechanisms:

• Some automatic machines employ pressure-based filling mechanisms, where the liquid is propelled into containers under controlled pressure conditions.

• This mechanism is particularly effective for carbonated beverages, maintaining the desired level of carbonation in the final product.

3. Vacuum Filling Technology:

Vacuum filling is another mechanical classification seen in advanced automatic machines. This technology involves creating a vacuum to draw liquid into containers, ensuring precise filling levels and minimizing air contact for improved product freshness.

Speed: 1000-2000CPH

Speed: 4000-8000CPH

Speed: 1500-2500CPH

Speed: 6000-10000CPH

Speed: 3000-6000CPH

Speed: 8000-15000CPH

Speed: 800-1500BPH

Speed: 5000-12000BPH

Speed: 2000-3000BPH

Speed: 3000-5000BPH

Speed: 800-1500BPH

Speed: 8000-10000BPH

Speed: 8000-10000BPH

Speed: 1800BPH

Speed: 3000-5000BPH

Speed: 5000-12000BPH

Speed: 14000BPH

Technical Excellence:

Our automatic beverage filling machines stand as a testament to our commitment to cutting-edge technology. At their core, these machines are equipped with advanced sensors and controls that ensure unparalleled accuracy in filling levels. Whether you are packaging carbonated soft drinks in cans or bottling premium juices, our machines guarantee consistent and precise filling, minimizing product wastage. This precision, coupled with high-speed capabilities, is achieved through the intricate synchronization of mechanical and digital components, resulting in a seamless filling process.

Versatility and Adaptability:

One of the hallmarks of our automatic beverage filling machines is their adaptability. They are classified based on the specific containers they handle, which include both cans and bottles. Our beverage can filling machines are engineered to accommodate aluminum and tin cans, ensuring precise filling and secure sealing. These machines are particularly suited for carbonated beverages, preserving the effervescence and taste. On the other hand, our beverage bottle filling machines offer a versatile solution for different bottle shapes and materials, whether glass or plastic. They adapt to various bottle sizes, guaranteeing uniform filling for a wide range of beverages.

Enhancing Production Efficiency:

In the competitive landscape of beverage production, efficiency is paramount. Our automatic beverage filling machines are designed with this principle in mind. They operate at high speeds, maximizing your production output. Their user-friendly interfaces streamline setup and operation, reducing downtime and increasing overall productivity. The robust construction of our machines ensures durability, guaranteeing a long-lasting solution for your beverage filling needs.

At Mic Machinery, we don't just provide equipment; we provide solutions that drive your beverage production to new heights. Our automatic beverage filling machines embody innovation, precision, and adaptability. They don't just meet industry standards; they set them. Choose us to shape the future of beverage filling technology and elevate your brand to new levels of success.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

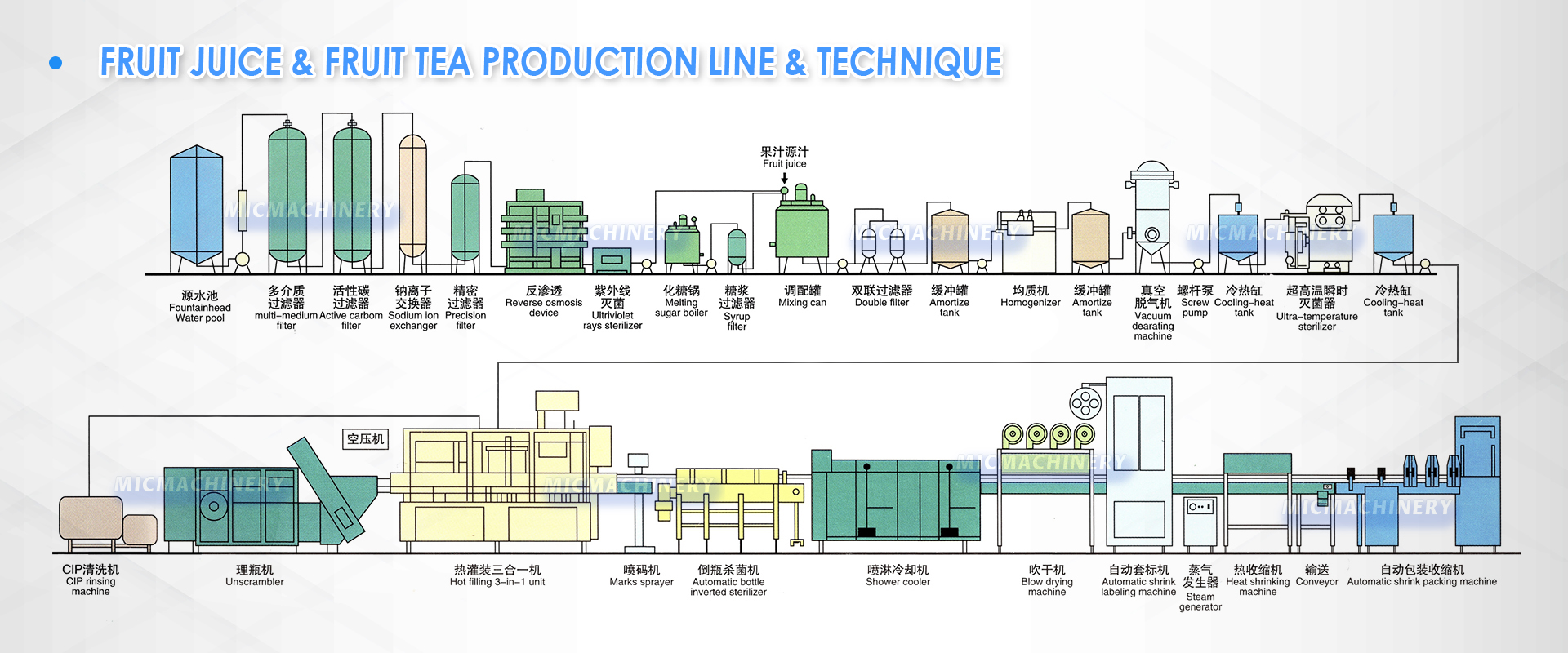

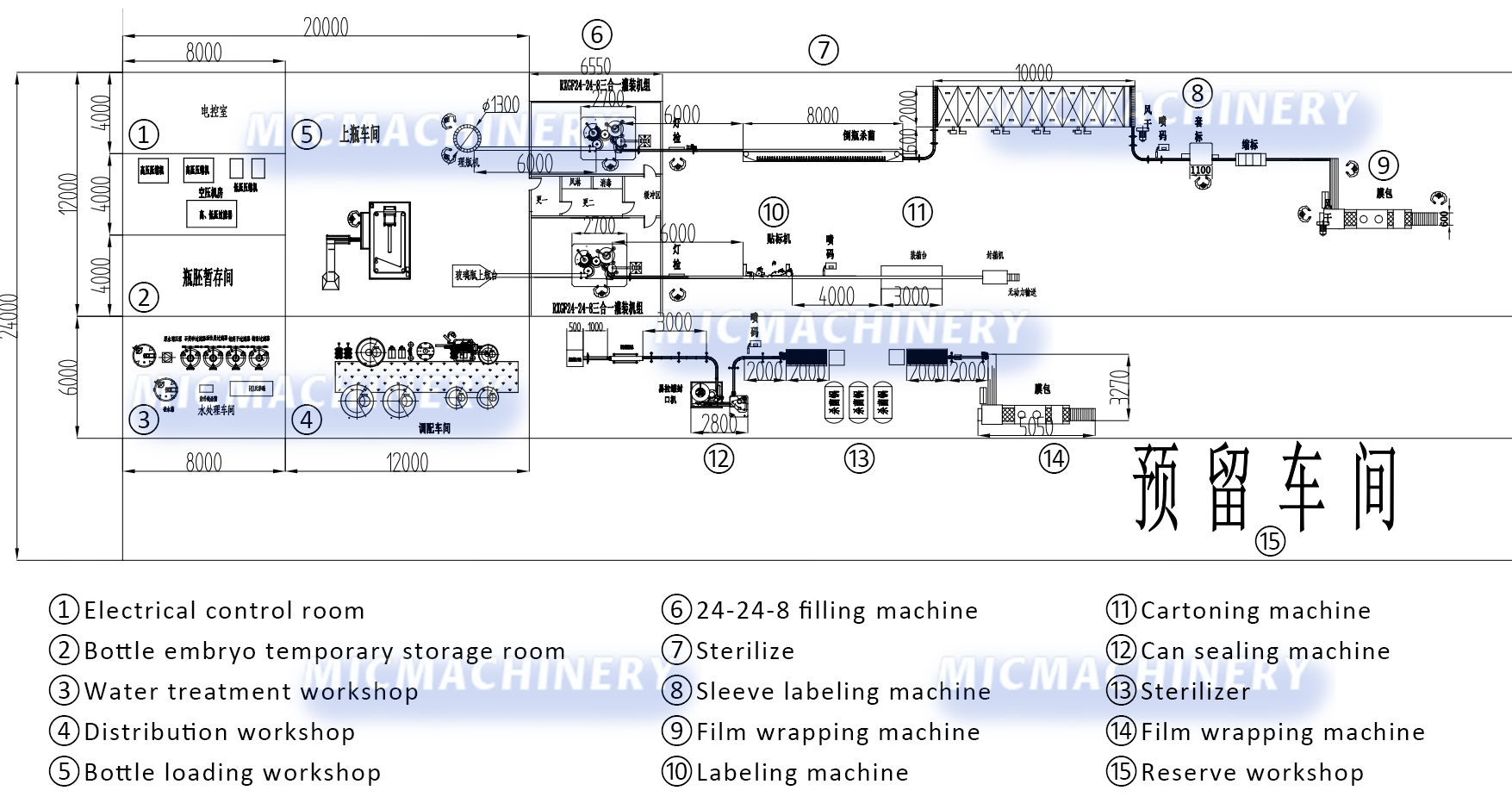

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine