Product Characteristics

1. Automated Precision Filling:

• At the core of Mic Machinery's Soda Bottle Plant Machine lies an automated precision filling mechanism, ensuring uniform and accurate fills for every bottle.

• This characteristic minimizes variations, delivering a consistent, high-quality product that meets and exceeds consumer expectations.

2. Versatility Across Beverage Types:

• The machine's adaptability stands out as a defining characteristic, accommodating a spectrum of beverages from soft drinks to beer.

• Customizable configurations empower manufacturers to tailor packaging solutions, meeting the unique characteristics of different beverages.

3. Dynamic Bottle Size Adaptability:

• Versatility extends to bottle sizes, providing manufacturers with the freedom to diversify their product offerings without extensive adjustments.

• Adjustable parameters facilitate seamless transitions between different bottle formats, reducing manual interventions and enhancing overall efficiency.

Product Application

1. Soda Bottling Precision:

• Mic Machinery's machine excels in soda bottling, ensuring each bottle receives a precise and consistent fill, preserving the beverage's quality and carbonation.

• The automated filling mechanism minimizes product variations, setting a new standard in soda packaging.

2. Efficient Beer Bottling Solutions:

• The beer bottling line for sale signifies our commitment to the brewing industry, offering efficient and adaptable solutions for beer packaging.

• The machine's characteristics align seamlessly with the nuanced requirements of beer production, ensuring optimal results.

3. Streamlined Soft Drink Packaging:

• Soft drink bottling lines benefit from the machine's versatility, as it caters to a wide range of soft drink formulations and packaging requirements.

• Customizable configurations and automated precision ensure a seamless soft drink bottling process, optimizing production efficiency.

Machine Usage

1. Adaptable Configurations for Varied Production Needs:

• The machine's usage is defined by its adaptability, allowing manufacturers to configure settings based on specific production requirements.

• Adaptable configurations enhance production flexibility, facilitating the seamless transition between different beverage types.

2. Streamlined Operations for Enhanced Efficiency:

• Automated operations streamline the entire production process, reducing downtime and enhancing overall efficiency.

• The machine's usage optimizes workflow, ensuring a consistent and efficient bottling process.

3. User-Friendly Interface for Intuitive Control:

• Mic Machinery's machine features a user-friendly interface, providing operators with intuitive control over the bottling process.

• Intuitive controls enhance the user experience, empowering operators to navigate the machine with ease.

Speed: 800-1500BPH

Speed: 3000-5000BPH

Speed: 200-800BPH

Speed: 800-1500BPH

Speed: 8000-10000BPH

Speed: 2000-3000BPH

Speed: 14000BPH

Automatic Soda Bottling Plant: Precision in Every Bottle

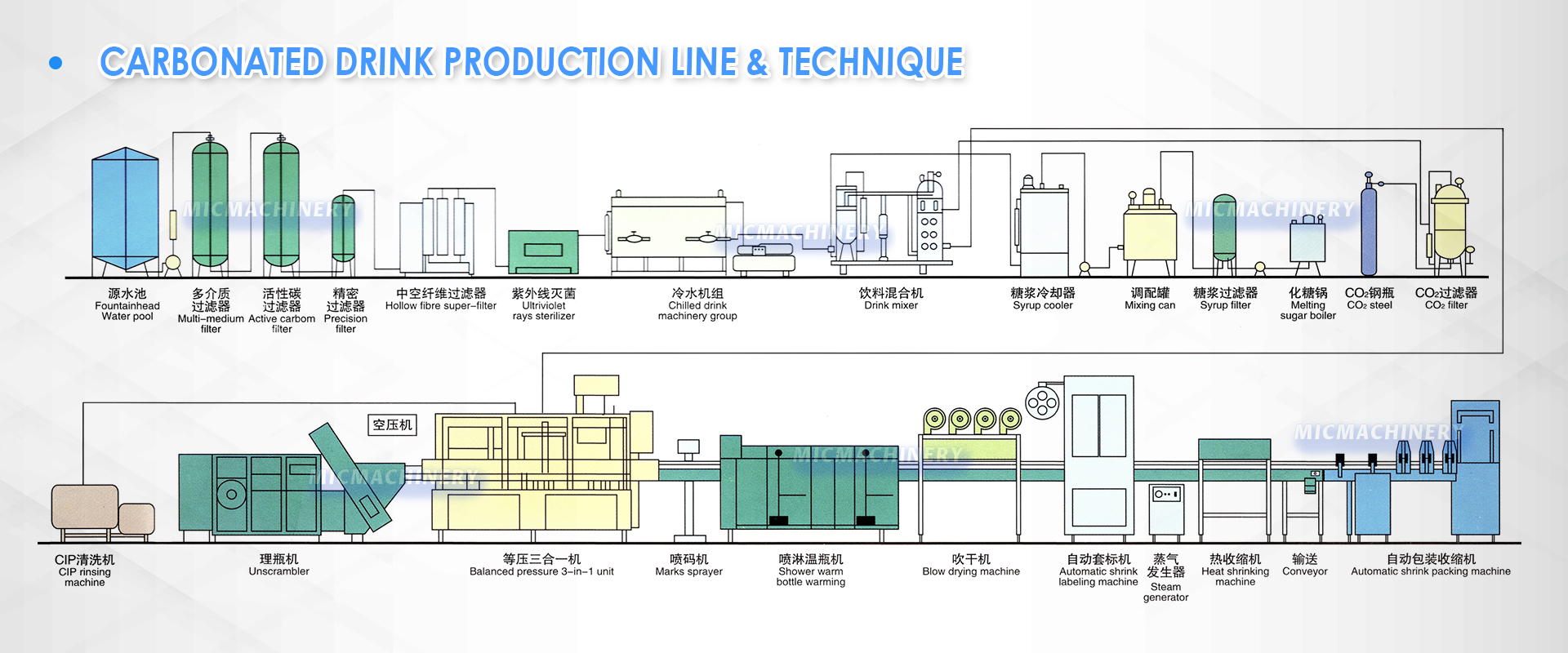

Our automatic soda bottling plant is a technological marvel, meticulously engineered to meet the high standards and demands of the modern beverage industry. This cutting-edge solution ensures a seamless and efficient bottling process, from carbonated soft drinks to beer, providing unparalleled precision and speed.

Key Features:

1. High-Speed Bottling Line:

Our automatic soda bottling plant boasts a high-speed production line, capable of handling large volumes of bottles per minute. This accelerates the bottling process, enhancing overall production efficiency.

2. Versatility Across Beverages:

Designed for versatility, our bottling plant is equipped to handle a diverse range of beverages, including carbonated soft drinks and beer. This adaptability makes it an ideal solution for manufacturers seeking a comprehensive and flexible production system.

3. Precision Filling Mechanism:

The heart of our bottling plant lies in its precision filling mechanism. This ensures accurate filling levels for each bottle, minimizing product wastage and maintaining consistent quality throughout the production run.

4. Efficient Capping and Sealing:

The automatic capping and sealing system guarantees a secure and hermetic seal for each bottle, preserving the freshness and carbonation of the beverages. This feature is particularly crucial for the beer bottling line for sale, ensuring the integrity of the final product.

5. User-Friendly Control Interface:

The bottling plant is equipped with an intuitive control interface, allowing operators to monitor and adjust parameters easily. This user-friendly design streamlines the operation and minimizes the learning curve for the production team.

Benefits for Beverage Manufacturers:

1. Increased Production Output:

The high-speed bottling line significantly increases production output, enabling beverage manufacturers to meet the growing demand for their products.

2. Consistent Product Quality:

Precision filling and sealing mechanisms contribute to maintaining consistent product quality, meeting the stringent standards expected in the beverage industry.

3. Adaptability to Market Demands:

The versatility of our automatic soda bottling plant allows manufacturers to adapt to changing market demands, facilitating the production of various beverages without the need for extensive retooling.

Beer Bottling Line for Sale: Elevate Your Brewing Operations

For breweries seeking to optimize their operations, Mic Machinery's beer bottling line for sale provides a turnkey solution for efficient and high-quality beer packaging. This specialized line integrates seamlessly with our automatic soda bottling plant, offering breweries a comprehensive and reliable solution for their bottling needs.

In conclusion, Mic Machinery's automatic soda bottling plant and beer bottling line for sale represent a leap forward in beverage production technology. Whether you are in search of soft drink bottling lines or a specialized beer bottling solution, our cutting-edge solutions are tailored to elevate your manufacturing processes.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine