Machine Characteristics

1. Temperature Control Technology:

• Cold Drink Filling Machines are equipped with advanced temperature control features, ensuring that the beverages are maintained at the optimal cold temperature throughout the filling process.

• This characteristic is crucial for preserving the freshness and taste of cold drinks, offering consumers an enjoyable and refreshing experience.

2. High-Speed Operation:

• Characterized by swift and efficient operations, these machines boast high-speed capabilities to meet the demands of fast-paced beverage production.

• The accelerated filling process not only enhances productivity but also contributes to meeting market demands with timely deliveries.

3. Adaptive Configurations:

• Cold Drink Filling Machines come with adaptable configurations, allowing for seamless adjustments to accommodate various bottle sizes, shapes, and packaging materials.

•This flexibility ensures that manufacturers can diversify their product range without the need for extensive retooling or adjustments.

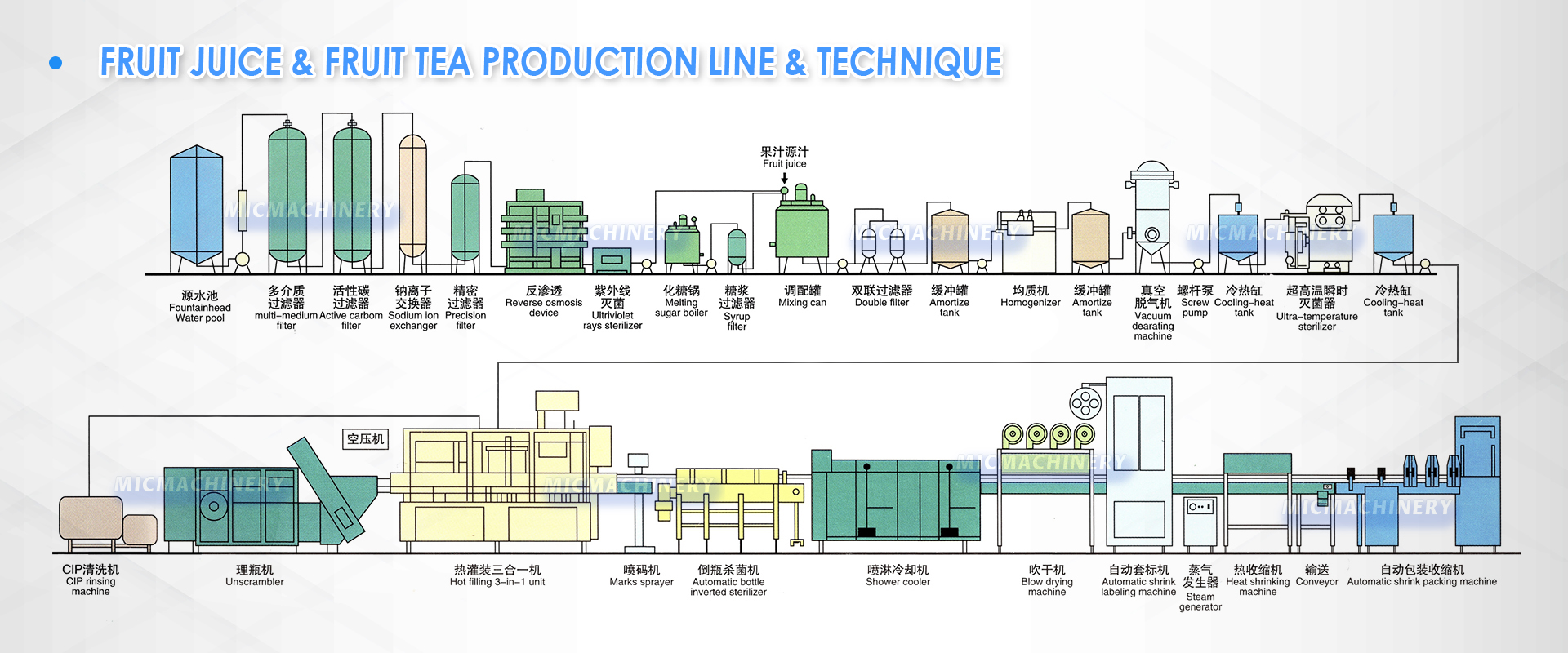

Product Application

1. Versatile Cold Beverage Packaging:

• Tailored for a variety of cold beverages, including carbonated drinks, iced teas, and flavored cold brews, these machines offer a versatile solution for the packaging needs of the cold drink industry.

• The adaptability of the equipment allows businesses to explore diverse product lines and cater to evolving consumer preferences.

2. Customizable Labeling and Packaging:

• Cold Drink Filling Machines often integrate intelligent labeling systems, enabling customizable branding and packaging options.

• Businesses can create a distinct identity for their cold drink products, fostering brand recognition and consumer loyalty.

Mechanical Principle

1. Pressure Filling Mechanism:

• The core mechanical principle of Cold Drink Filling Machines often involves pressure filling mechanisms, where beverages are propelled into containers under controlled pressure conditions.

• This technology ensures precise filling levels, particularly crucial for maintaining carbonation levels in carbonated cold drinks.

2. Vacuum Sealing Technology:

• Advanced machines leverage vacuum sealing technology to secure airtight seals on cold drink containers.

• This method minimizes the exposure of cold beverages to external air, preserving their freshness and extending shelf life.

3. Smart Automation and Controls:

• Cold Drink Filling Machines incorporate smart automation and control systems, optimizing the packaging process with minimal human intervention.

• This not only enhances efficiency but also reduces the risk of errors, ensuring a consistently high-quality output.

Speed: 1000-2000CPH

Speed: 4000-8000CPH

Speed: 1000-1500CPH

Speed: 1500-2500CPH

Speed: 6000-10000CPH

Speed: 480CPH

Speed: 3000-6000CPH

Speed: 8000-15000CPH

Speed: 1800CPH

Speed: 800-1500BPH

Speed: 5000-12000BPH

Speed: 2000-3000BPH

Speed: 200-800BPH

Speed: 800-1500BPH

Speed: 8000-10000BPH

Speed: 8000-10000BPH

Speed: 3000-5000BPH

Speed: 3000-5000BPH

Speed: 5000-12000BPH

Speed: 14000BPH

Speed: 1800BPH

In the dynamic landscape of beverage manufacturing, precision and efficiency are non-negotiable, especially when it comes to cold drink packaging. At Mic Machinery, we stand as pioneers in the field, offering state-of-the-art Cold Drink Filling Machines designed to redefine the standards of excellence in the industry. Allow us to introduce you to our company, where innovation meets reliability, and where your cold drink production aspirations find a trusted partner.

Advanced Cold Drink Packaging Machines:

At the heart of our offerings are the advanced Cold Drink Packaging Machines, meticulously crafted to cater to the diverse needs of the beverage industry. Our machines embody the perfect synergy of cutting-edge technology and intelligent design, ensuring a seamless and efficient cold drink filling process.

Key Features of Our Cold Drink Filling Machines:

• Temperature Control Expertise:

Our machines are equipped with sophisticated temperature control technology, guaranteeing that your cold beverages are maintained at optimal temperatures throughout the packaging process. This not only preserves the refreshing quality of your drinks but also contributes to a superior consumer experience.

• High-Speed Precision:

We understand the importance of speed in the modern beverage industry. That's why our Cold Drink Filling Machines boast high-speed capabilities, facilitating rapid and precise filling to meet the demands of a fast-paced market.• Adaptable Configurations:

Flexibility is key, and our machines are designed with this principle in mind. With adaptable configurations, you can effortlessly adjust the settings to accommodate various bottle sizes, shapes, and packaging materials. Diversify your product range without the hassle of extensive retooling.

Unparalleled Technical Excellence:

• Pressure Filling Mechanism:

The mechanical principle at the core of our Cold Drink Filling Machines involves advanced pressure filling mechanisms. This ensures the precise propulsion of beverages into containers under controlled pressure conditions, maintaining the desired carbonation levels in carbonated drinks.• Vacuum Sealing Technology:

Our machines leverage vacuum sealing technology for airtight seals on cold drink containers. This technology not only enhances product freshness but also extends the shelf life of your beverages.

Competitive Cold Drink Filling Machine Prices:

• Cost-Efficient Solutions:

At Mic Machinery, we believe in offering cost-effective solutions without compromising on quality. Our Cold Drink Filling Machines are competitively priced, and the long-term benefits they bring, including reduced manual labor, minimized wastage, and optimized production, make them a wise investment for your business.• Tailored to Your Budget:

Recognizing that businesses have diverse budgets, we provide a range of Cold Drink Filling Machine options. Choose a machine that aligns seamlessly with your financial considerations while delivering the production capacity and features that suit your specific requirements.

Why Choose Mic Machinery for Cold Drink Filling Machines?

• Innovation Meets Reliability: Our machines embody the latest technological advancements while maintaining a reputation for reliability and durability.

• Industry Expertise: With years of experience in the beverage packaging industry, we understand the unique challenges and requirements of cold drink production.

• Customer-Centric Approach: At MIc Machinery, we prioritize customer satisfaction. Our dedicated support team is always ready to assist you, ensuring a smooth and successful integration of our machines into your production line.

Elevate your cold drink production with the unmatched precision and efficiency of Mic Machinery's Cold Drink Filling Machines. Explore a new era of beverage packaging technology and stay ahead in the competitive market. Contact us today to embark on a journey of innovation and success.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine