Machine Application

1. Injection Molding Machine:

• Shapes PET resin into preforms for the plastic water bottle production line.

• Essential for ensuring consistent quality in preform production.

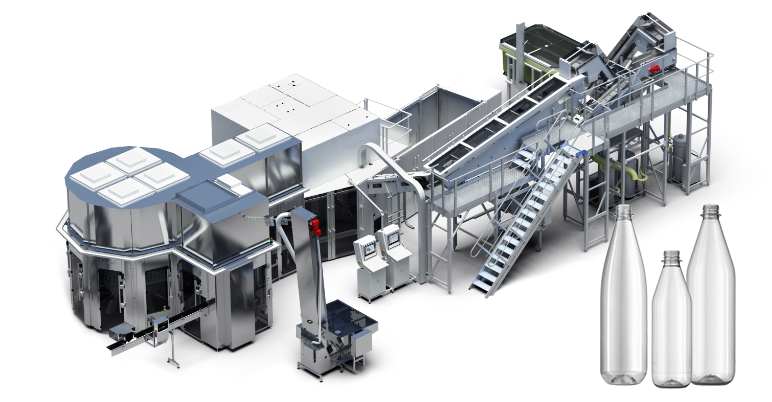

2. Stretch Blow Molding Machine:

• Transforms preforms into the desired bottle shape in the PET filling line.

• Utilizes heat and pressure for uniform bottle design.

3. Filling Machine:

• Precision equipment for filling bottles with water or beverages in the plastic water bottle production line.

• Ensures accuracy and efficiency in the filling process.

4. Capping Machine:

• Secures a tight seal on bottles, concluding the PET filling line process.

• Final step in the plastic water bottle production line, ensuring product integrity.

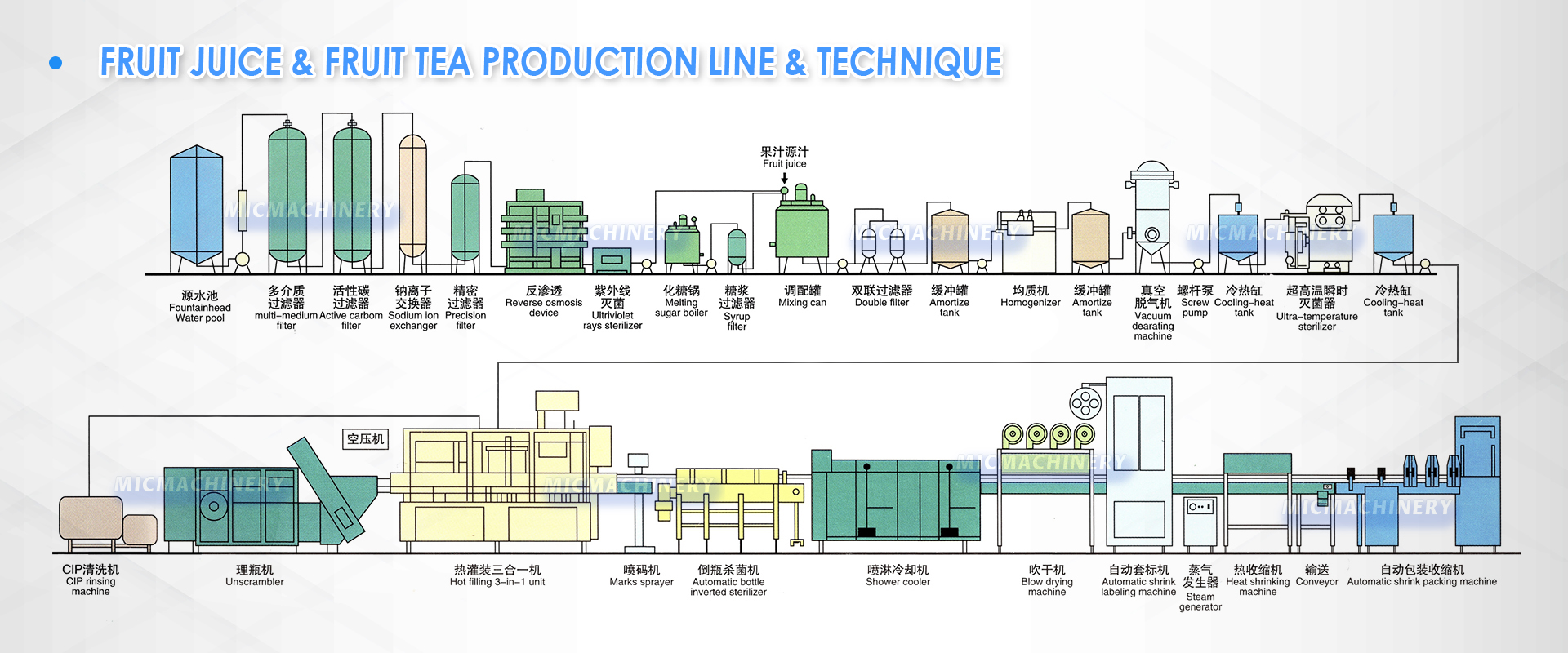

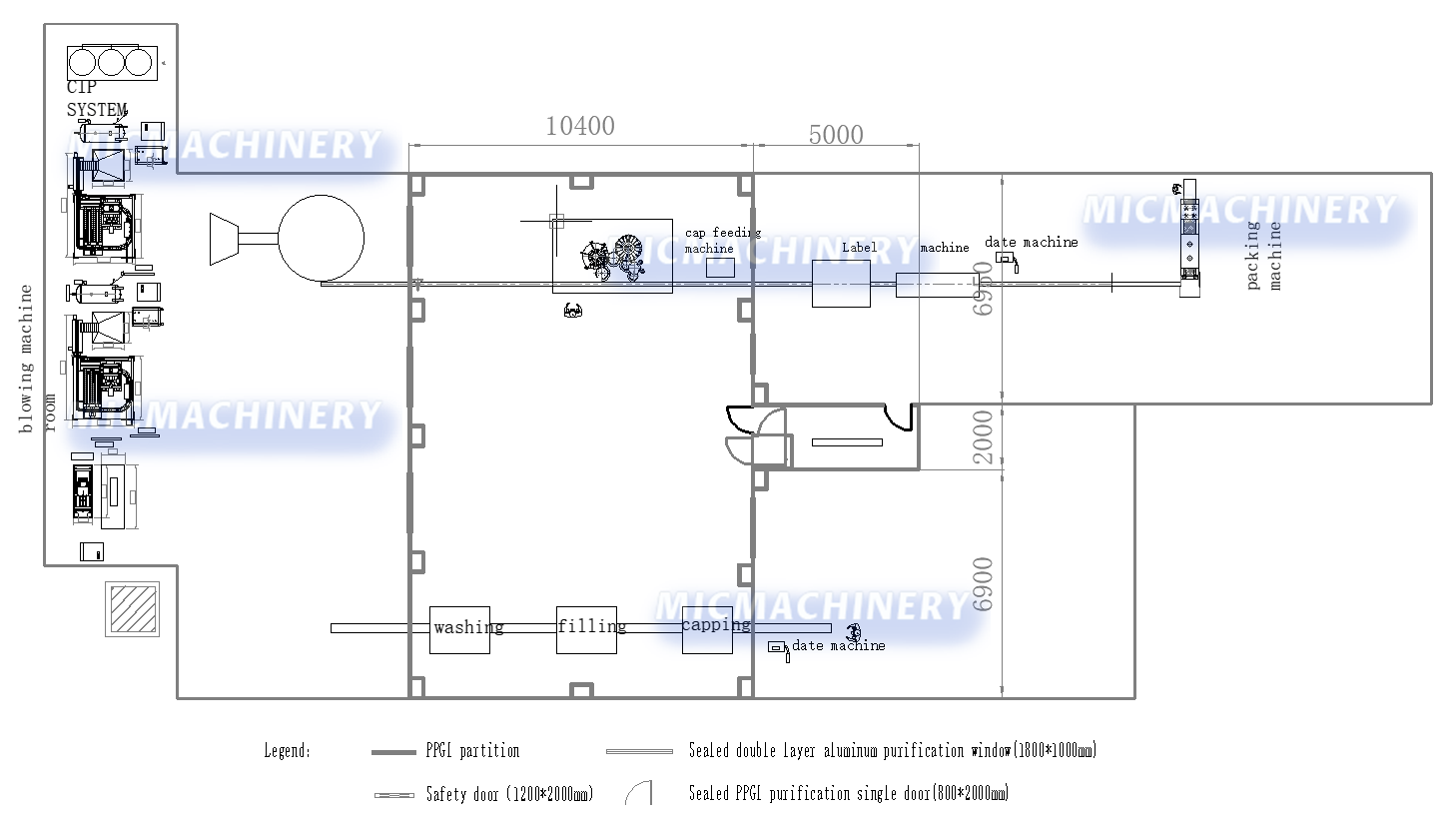

Machine Workflow

1. Injection Molding to Stretch Blow Molding:

• Injection molding in the plastic water bottle production line shapes PET resin into preforms.

• Preforms undergo a transformation in the stretch blow molding machine, ensuring consistent bottle shaping.

2. Filling Process:

• Bottles move from molding to the filling machine in the PET filling line.

• Accurate and swift filling of bottles with water or beverages.

• Maintains quality throughout the plastic water bottle production line.

3. Capping and Finalization:

• Capping machine securely seals filled bottles, concluding the PET filling line.

• Finalizes the plastic water bottle production line, preparing bottles for distribution.

Machine Parameters

1. Injection Molding Parameters:

• Optimal mold temperatures for quality preform production in the plastic water bottle production line.

• Adjusted injection pressures to achieve precise molding.

2. Stretch Blow Molding Parameters:

• Heat and pressure settings tailored for uniform bottle shaping in the PET filling line.

• Ensures consistency in the final plastic water bottle product.

3. Filling Machine Parameters:

• Adjustable bottle filling speeds for efficiency in the plastic water bottle production line.

• Precision settings to maintain high product quality.

4. Overall Optimization:

• Fine-tuned machine parameters contribute to energy efficiency in the PET filling line.

• Cost-effective production achieved through optimization in the plastic water bottle production line.

Speed: 3000-5000BPH

Speed: 1800-2200BPH

Speed: 5000-6000BPH

Speed: 3000-6000BPH

Expertise in Plastic Water Bottle Production Line:

Comprehensive PET Filling Line Solutions:

Key Features of Mic Machinery PET Bottle Production Lines:

1. Advanced Injection Molding Technology:

Our plastic water bottle production lines leverage cutting-edge injection molding technology to shape PET resin into preforms with unmatched precision.

The stretch blow molding process is optimized for efficiency, ensuring uniform bottle shaping through controlled heat and pressure.

3. Integrated PET Filling Solutions:

We offer fully integrated PET filling lines that seamlessly complement our plastic water bottle production lines, providing end-to-end solutions.

4. Customizable Machine Parameters:

Tailor our machines to your specific needs with adjustable parameters, including mold temperatures, injection pressures, and filling speeds.

1. Industry Leadership:

As a recognized industry leader, we set the standard for excellence in plastic water bottle production lines and PET filling solutions.

2. Innovation and Technology:

Our commitment to innovation drives the continuous evolution of our technology, ensuring our clients stay ahead in a competitive market.

3. Reliability and Quality:

Delivering reliable and high-quality solutions is at the core of our mission, establishing trust with our clients.

Choose Mic Machinery for a transformative partnership in plastic water bottle production lines and PET filling solutions. Experience innovation, reliability, and unparalleled excellence in every aspect of beverage packaging.

- Beer filling machine solution

- Carbonated drink filling machine solution

- Soda water filling project solution

- Edible oil filling project solution

- Beverage filling equipment

- Drink water packing machine

- Beverage bottling equipment

- Automatic beverage filling machine

- Cold drink filling machine

- Water filling machine

- Mineral water filling machine

- Water bottle filling machine

- Pure water filling machine

- Bottled water filling machine

- Juice filling equipment

- PET bottle juice filling machine

- Soft drink can filling machine

- Juice bottle filling machine

- Fruit juice packaging machine

- Small juice filling machine

- Juice bottle packing machine

- Soda bottle machine price

- Soda can filling machine

- Soda bottle filling machine

- PET bottle soda filling machine

- Carbonated soft drink filling machine

- Small carbonated drink filling machine

- Soda gas filling machine

- Soda water filling machine

- Beer bottling equipment

- Automatic beer filler

- Automatic beer bottling machine

- Beer filling equipment

- Semi automatic soda filling machine price

- Wine bottling line

- Liquor bottle filling machine

- Bottling production line

- PET bottle production line

- Bottling line

- PET bottling line

- Soda bottling plant machine

- Soda bottle plant machine

- Soda PET bottle filling machine

- Soda can production line

- Soda bottling machine price

- Beverage filling machine manufacturers

- Beverage filling line

- Beverage production line

- Juice production line

- Juice filling line

- Beer filling line

- Beer production line

- Craft beer canning line

- Mineral water filling line

- Mineral water bottle filling machine

- Bottled water production line

- Water bottle production line

- Water filling line

- Automatic water bottle filling machine

- Water bottling equipment

- Water bottling line

- Bottling plant machine

- Water filling plant

- Automatic water bottling machine

- Drinking water filling machine

- Water bottle filling plant

- Water filling production line

- Small water filling machine

- Water bottle filling equipment

- Water bottling line for sale

- Glass bottle water filling machine

- Water bottle plant machine

- Automatic bottle filling plant

- Bottle mineral water filling machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine