- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

1.1 Machine information

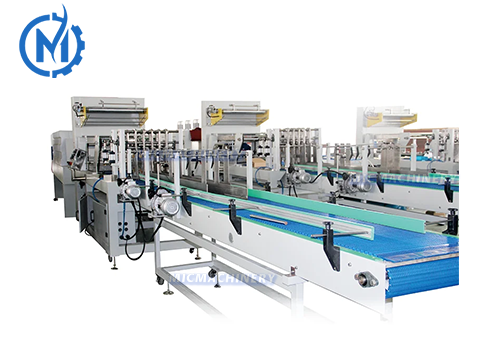

Using advanced constant temperature membrane heat binding technology in the world with clear and secure seal. The quick seal cooling structure guarantee that the seal has a higher strength even if under high speed production condition.

Adopt with PLC automatic program circulation control with stable and reliable performance. The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss.

All the transfer system is controlled by frequency changing devices. With stable and smooth transfer speed. Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

Title: Enhancing Packaging Efficiency: The Performance of Seal and Shrink Packaging Machine

In modern manufacturing, efficient and reliable packaging is essential for product protection and presentation. The Seal and Shrink Packaging Machine emerges as a versatile solution, offering seamless packaging for various products. Let's explore how this equipment optimizes performance, focusing on its role as a wrap packing machine, shrink wrapping machine, and automatic wrapping machine.

Maximizing Performance with Seal and Shrink Packaging Machine

Efficiency Enhancement: The Seal and Shrink Packaging Machine operates with exceptional efficiency, facilitating rapid packaging of products. With its advanced sealing and shrinking capabilities, this equipment streamlines the packaging process, reducing production downtime and maximizing throughput.

Versatile Packaging Solutions: Whether it's individual items or multi-packs, this machine offers versatile packaging solutions to meet diverse product requirements. It can efficiently wrap and shrink-wrap various items, providing flexibility in packaging options.

Precision and Consistency: Equipped with advanced sealing and shrinking mechanisms, the Seal and Shrink Packaging Machine ensures precise and consistent packaging results. Whether sealing or shrinking, the equipment delivers uniform packaging, enhancing product presentation and brand image.

Serving as a Wrap Packing Machine, Shrink Wrapping Machine, and Automatic Wrapping Machine

Wrap Packing Machine: As a wrap packing machine, the Seal and Shrink Packaging Machine efficiently wraps products in protective packaging materials, such as film or paper. This packaging method offers additional protection and improves product visibility on retail shelves.

Shrink Wrapping Machine: The Seal and Shrink Packaging Machine excels as a shrink wrapping machine, applying heat to shrink-wrap products tightly in plastic film. This process not only secures the products but also enhances their appearance, creating a professional and tamper-evident packaging solution.

Automatic Wrapping Machine: Offering fully automated operation, the Seal and Shrink Packaging Machine functions as an automatic wrapping machine, minimizing the need for manual intervention. Programmable settings and intuitive controls ensure seamless integration into production lines, optimizing workflow and productivity.

Conclusion

In the domain of packaging, the Seal and Shrink Packaging Machine stands as a symbol of efficiency, versatility, and precision. Whether serving as a wrap packing machine, shrink wrapping machine, or automatic wrapping machine, it plays a crucial role in streamlining packaging processes and maintaining product quality. By investing in this advanced equipment, manufacturers can optimize their operations, enhance product presentation, and meet consumer expectations with confidence.

Technical parameters

|

Dimension for the whole machine |

L11083mm*W1100mm*H2100mm |

|

Thermal shrinkage passage dimension |

L2400mm*W650mm*H450mm |

|

Max package dimension |

L600mm*W400mm*H350mm |

|

Packaging speed |

10-15Pcs/minute |

|

Transfer belt width |

550mm |

|

Sealing and cutting time/temperature |

0.5-1.5s 180°C-260°C |

|

Operating power supply/power |

380V 30kw |

|

Operating air pressure |

0.6-0.8Mpa |

|

Air Consumption |

0.6m3/minute |

Electrical Configuration

Remark: Our machine use Three phase : 380V/50HZ

If your country electricity is different , please tell me .

|

No |

Item |

Amount |

Brand |

Origin |

|

1 |

Miniature circuit breaker |

3 |

Schneider |

France |

|

2 |

A.C.contactor |

4 |

Schneider |

France |

|

3 |

PLC |

1 |

Siemens |

Germany |

|

4 |

Touch screen |

1 |

Siemens |

Germany |

|

5 |

Frequency transformer |

1 |

Siemens |

Germany |

|

6 |

Cylinder |

3 |

SMC |

Japan |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine