- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

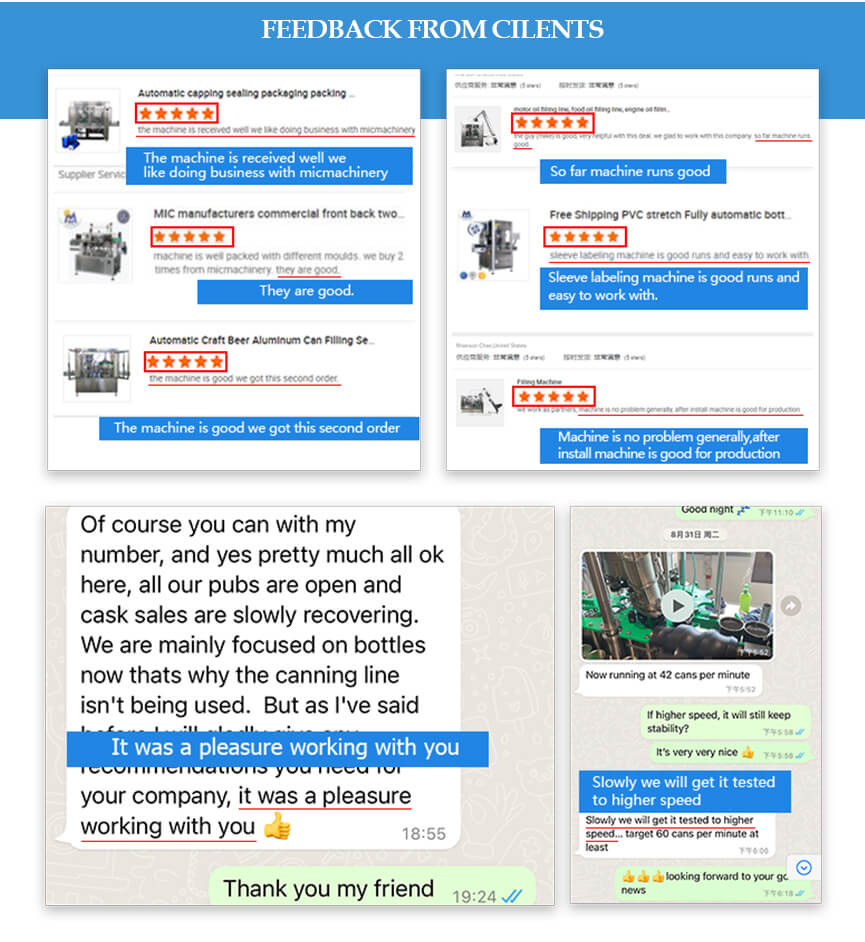

- Customer reviews: click on

MIC 18-6 It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry.

Adopt products: beer , craft beer , gas water, carbonated water, co2 water, etc liquid like carbonated drinks.

Machine working principle:

The machine adopts PLC, frequency converter, human machine interface controlling system, having the advanced controlling technologies, such as frequency control, no can no filling and so on.

The accurate production rate and quantity will be displayed on touch-screen via the kinds of sensors on the machine.

Moreover, the production rate can be set on the touch screen.

The main motor and other electrical equipments are all in protection state.

Meanwhile all of the malfunctions can be found out easily, because they will be displayed on the touch screen.

The main electric and pneumatic components of the machine are famous imported brands, and it also can be disposed according to client’s requirements.

For this production line you might be interested in:

Related machines are: can filling seaming machine, can seaming machine, rotated oil can filling machine, rotated oil filling machine, beer filling machine, beer seaming machine, beer bottling machine and beer filler.

CAN SEAMING TEST

| Model | MIC-18-6 |

|---|---|

| Filling heads | 18pcs |

| Capping heads | 6pcs |

| Volume | 0.1-1.5L |

| Production capacity | 2000-6000bottle/hr base on 500ml |

| Filling method | Isobaric |

| Power | 2.5kw 380V/50HZ(According to customer) |

| Air pressure | 0.7Mpa |

| Gas consumption | 0.8m³/min |

| Water consumption for bottle washing | 0.5-1T/H |

| Wash bottle water pressure | 0.2~0.25 Mpa |

| Weight | 4500kg |

| Dimension | 3000×1800×2500mm |

| Electrical configuration | |

|---|---|

| Touch screen | MITSUBISHI |

| Frequency converter | MITSUBISHI |

| PLC | MITSUBISHI |

| Contactor, breaker | DELIXI |

| Proximity switch | DELIXI |

| Photoelectric switch | DELIXI |

| Bearing | Harbin |

| Relay | OMRON |

| Barometer | AirTAC |

| Air cylinder | AirTAC |

| Solenoid valve | AirTAC |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine