- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

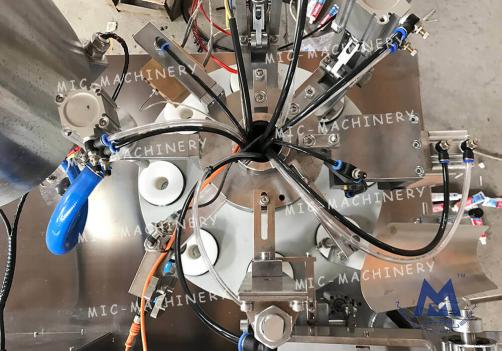

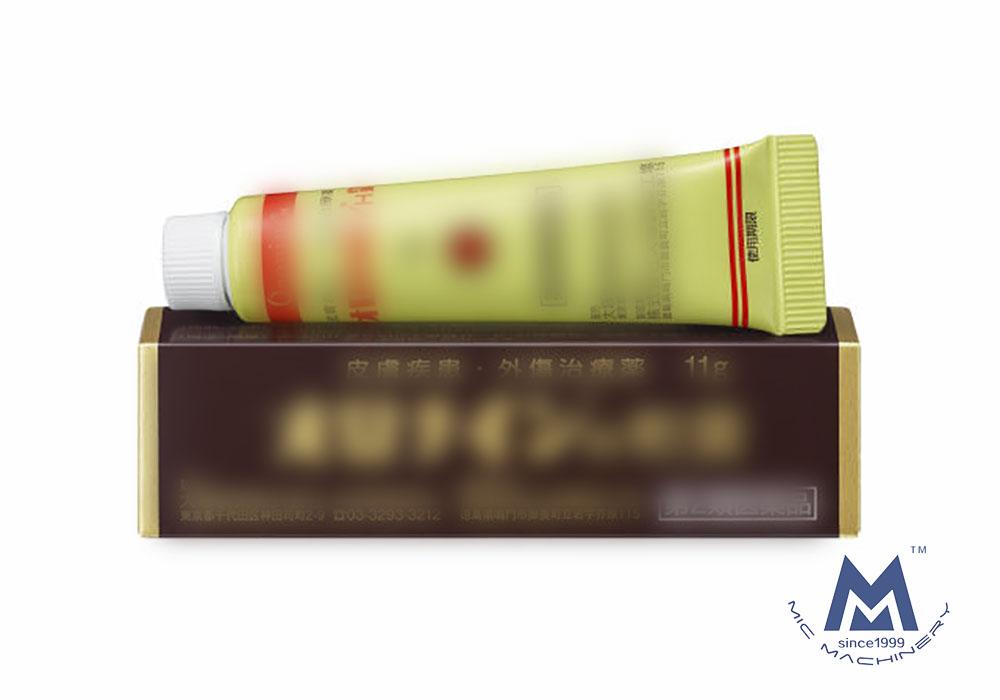

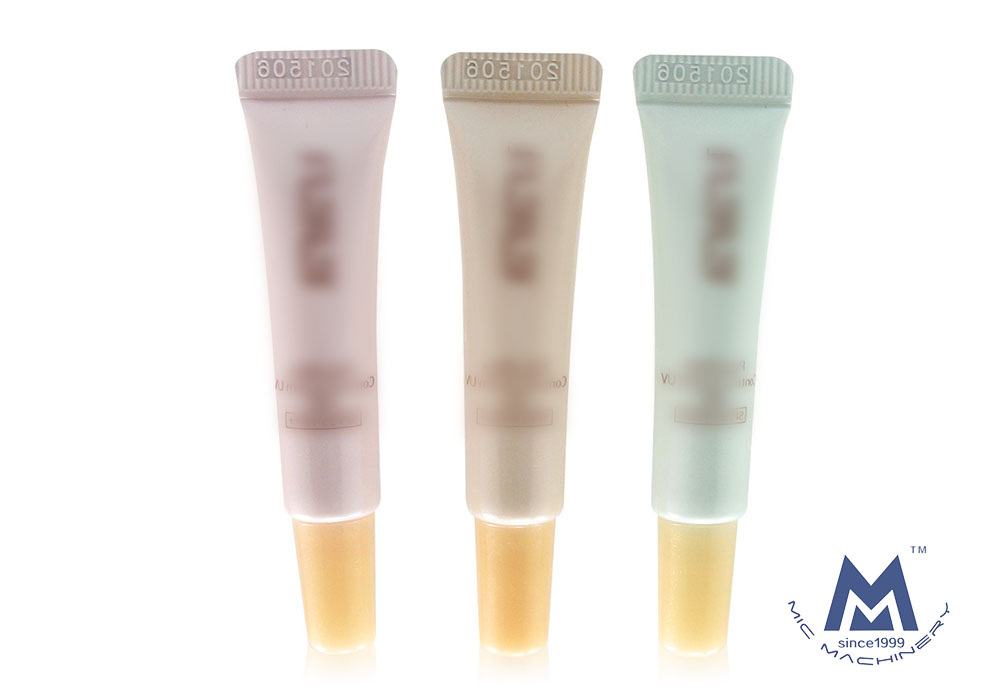

This tube filling & sealing machine, tube filling & sealing machine, plastic tube filling sealing machine is a high technical equipment which successfully developed and designed by introducing into advanced overseas technology and integrating GMP requirement. It adopts with PLC controller, automatically operating from liquid or high velocity material filling till batch number printing (include manufacture date), it's an ideal equipment for ALU tube, plastic tube and multiple tube filling and sealing in cosmetic, pharmacy, foodstuff, adhesives etc industries.

1. The transmission part of the platform or less closed, safe, reliable, non-polluting;

2. Filling and sealing portion is mounted on the platform within no more than half an enclosed frame static visual cover, easy to observe, easy operation and maintenance;

3. PLC control, man-machine dialogue interfaces;

4. Distant dial to cam driven, high speed, high precision;

5. Inclined tube compartment, the tube body with a vacuum suction device to ensure accurate automatic tube into the tube holder;

6. Photoelectric standard workstation, with high precision probes, stepper motor control hose pattern in the correct position;

7. Filling the mouth with a blanking mechanism to ensure that the filling quality;

8. No controls are not filling;

9. Sealing use (Leister hot air gun) end of the tube internal heating, cooling device external configuration;

10. Typing the code word workstation automatically print at the position on the technical requirements;

11. Plastic robot hose tail cut at right angles or rounded for selection;

12. Fault Baojing, ductless alarm, the door opened down, overload shutdown;

13. Stop counting and quantitative

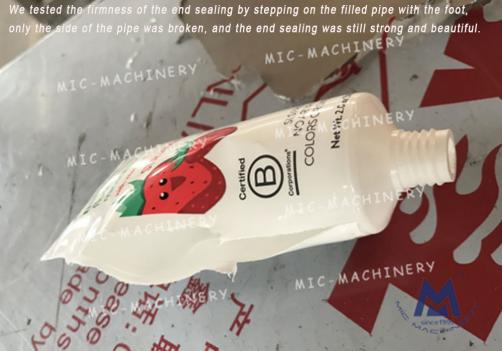

In the tail seal:We tested the firmness of the end sealing by stepping on the filled pipe with the foot, only the side of the pipe was broken, and the end sealing was still strong and beautiful.

Thank you for the reading this article,

you can also check for:

|

Voltage |

110V/220V/380V |

|

Power |

1.1kw |

|

Heating Power |

400w*2 |

|

Air Pressure |

0.6-0.8Mpa |

|

Production Capacity |

25-45 tubes/min |

|

Filling Volume |

1-300ml |

|

Filling Error |

±0.5g |

|

Material |

SS304/316 |

|

Dimensions |

1500*700*1800mm |

|

Weight |

475KG |

| Parts | Brand |

|

Main Motor |

Wu XI Qi Peng |

|

PLC |

Panasonic JAPAN |

|

Stepping Motor |

East Japan |

|

Stepping Drive |

East Japan |

|

Sensor |

Germany Sick |

|

Approach Switch |

BFNFC |

|

Intermediate Relay |

Schneider |

|

electromagnetic Valve |

Si Mai Ge |

|

Encoder |

Omron |

|

Mixing Motor (Optional) |

XiangGang Ease |

|

Air Cylinder |

Si Mai Ge |

|

Bearing |

Nsk |

|

Button |

Schneider |

|

Air Switch |

CHNT |

|

Power Switch |

Omron |

|

Temperature Control |

HuoYU |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine