- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

Manufacturers of case packing machine understand the diverse needs of the packaging industry and offer a wide range of solutions to accommodate various product types, case sizes, and production volumes. From compact tabletop models suitable for small-scale operations to high-speed fully automated systems capable of handling large-scale production demands, these machines are engineered to deliver consistent and reliable performance across different applications.

One of the key advantages of case packing machine is their versatility. These machines can handle a wide range of products, including bottles, cans, jars, pouches, and boxes, making them ideal for industries such as food and beverage, pharmaceuticals, cosmetics, and more. Whether it's primary packaging such as individual bottles or secondary packaging like grouped products, case packaging machine ensure precise and efficient packing into cases or cartons.

Leading case packing machine manufacturers leverage advanced technology and innovation to continually improve machine performance and capabilities. These manufacturers invest in research and development to introduce features such as servo-driven systems for precise control, quick changeover capabilities for increased flexibility, and integration with upstream and downstream equipment for seamless production flow.

The advent of automatic carton packing machine has further revolutionized the packaging industry by offering fully automated solutions for case packing. These machines can perform tasks such as case erection, product loading, case sealing, and labeling with minimal human intervention, significantly increasing production throughput and efficiency while reducing labor costs.

In summary, the case packing machine and its variants such as case packaging machine and automatic carton packing machine are indispensable assets for modern packaging operations. With their versatility, reliability, and efficiency, these machines ensure smooth and efficient packing processes, ultimately contributing to enhanced productivity, reduced costs, and improved competitiveness in the marketplace.

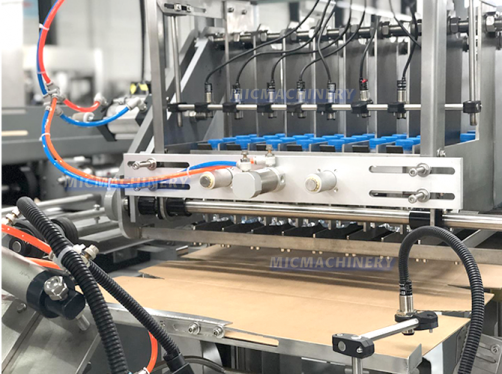

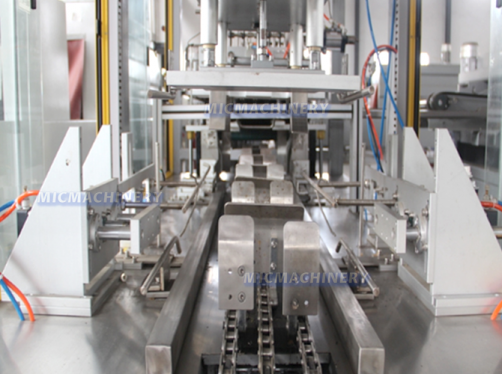

Bottle are separated to multi channel at conveyor, and then group by bottle separate fracture evenly. Bottle are grouped , then drop to cardboard via bottle drop fracture. At drop fracture with bottle and cardboard fall procedure, via one group of form block board, then card board fold to carton form. Via main drive with carton move forward, at the same time, via glue spray fracture to finish carton top glue spray, again the cam fracture via top ledge fold, at the same top carton fold to finish top sticking. Carton move forwarder, again via glue spray fracture to finish carton side glue spray, and via side pressure and carton press fracture to finish carton finally form and sticking, and via main drive let carton move forwarder to conveyor .

◆ Machine Parts

Technical parameter

|

Name |

Case packing machine |

Power supply |

380V,three-phase |

|

Production capacity |

10-14case/ minute |

Power supply |

220V AC |

|

Hot glue solidify time |

≤1.5-2S |

Main machine power |

10KW |

|

weight |

3.5T |

Gas consumption quantity |

1500 L/min |

|

Machine overall size |

6285*2582*2115 |

Compressor air requirement |

0.6~0.8MPa |

|

Bottle enter size |

3000*620*1200 |

Package product overall size |

(350-450) |

|

Cardboard specific requirement |

Material: corrugate, carton indentation thread thickness is moderate, width is not bigger than 2mm |

||

Related collocation description:

|

Name |

Model |

Amount |

Brand |

Original |

|

Miniature circuit breaker |

4P C20 |

1 |

Schneider |

France |

|

Miniature circuit breaker |

1P C10 |

1 |

Schneider |

France |

|

A.C.contactor |

E1810 |

1 |

Schneider |

France |

|

A.C.contactor |

E09104 |

3 |

Schneider |

France |

|

Switching power supply |

S8JC-Z05024C |

1 |

Schneider |

France |

|

PLC |

SIMATIC S7-200 |

1 |

Siemens |

Germany |

|

Touch screen |

SMART 700 IE V3 |

1 |

Siemens |

Germany |

|

Frequency transformer |

SINAMICS V20 |

1 |

Siemens |

Germany |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine