- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

MIC 24-24-6 It is applicable for glass bottle filling capping machine for whisky, alcohol drinks and spirit. (if need hot filling temperature at 85-90 degree)

Adopt products: whisky ,alcohol drinks, spirit, chivas, liquor, vodka, vinegar, soy sauce etc liquid products.

Machine working principle:

1. The beer filler height adjustable and crowner heads for different height of bottle. Designed cap hopper and transporter, less cap distortion, simpler structure and easier for clearing.

2. The crowner can be fully decrease the bacterial pollution.

3. Fast change over parts, such as bottle in feed worm, star wheel and guiding board.

4. Programmable controller automatically controls the filling steps, cullet flushing, filling valve opening/closing.

High pressure foaming.

5. It is a good beer machine for small and middle beer maker.

6. The machine is rotary design, Used for the production of various kinds of beer

7. This machine use pressure filling, liquid surface positioning. The machine for automatic control.

8. Through the touch screen to operate the machine.

For this production line you might be interested in:

3> Sticker labeling machine

4> Liquid level detective machine

5> Metal element detective machine

6> Nitrogen filling machine

7> CIP cleaning system

8> Pasteurization, inventor and sterilizing tunnel.

9> Glass bottle air washing machine

Related machines are: Glass bottle filling machine, glass bottle capper, glass bottling companies, bottle filling machine, bottle equiment, bottle filling, bottle filling capping machine, bottle filler, bottle capper, bottle capping machine, crown bottle capper, bottle capping machine price, Whisky filling capping machine, vodka filling capping machine, liquor filling machine, spirit filling machine

Carbonated beverage bottling equipment is a specialized machine used in the production of carbonated drinks. It is designed to handle the unique requirements of carbonated beverages, such as maintaining carbonation levels and preventing oxidation. The equipment is used by beverage companies to produce a variety of carbonated drinks, including soft drinks, energy drinks, sparkling water, and beer.

Carbonated beverage bottling equipment is available in different models, ranging from semi-automatic machines to fully automated systems. These machines can handle various bottle sizes and shapes, including glass bottles, PET bottles, and cans. They can also perform multiple functions, such as bottle cleaning, filling, capping, labeling, and packaging.

One of the key features of carbonated beverage bottling equipment is its ability to maintain the carbonation level of the drinks during the bottling process. The machines are equipped with specialized valves and filling systems that prevent the escape of carbon dioxide gas, ensuring that the carbonation level is maintained in the final product.

Another key feature of carbonated beverage bottling equipment is its high level of automation. The machines are designed to operate efficiently and effectively, with minimal human intervention. This reduces the risk of errors and increases production capacity, making it a cost-effective solution for beverage companies.

In summary, carbonated beverage bottling equipment is a critical component of the carbonated drink production process. Its ability to maintain carbonation levels, high level of automation, and versatility make it an essential investment for beverage companies looking to improve their production processes and increase efficiency.

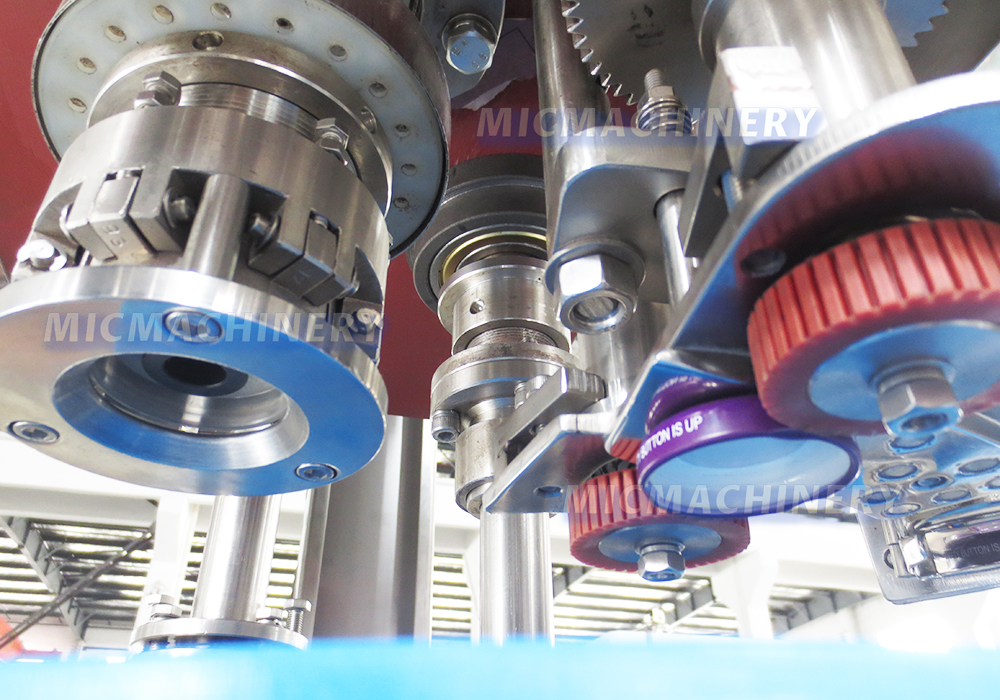

Capping Part

Capping part is mainly composed of capping heads, cap loader (separated), cap unscrambler, cap drop rail, pressure regular, cylinder and also we need an air compressor as the auxiliary external equipment.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. The capper is equipped with inlet bottle detection switch.

Filling Part

Filling part is mainly composed of filling barrel, filling valve (low temperature and isobar filling), filling pump, bottle hanging device / bottle pedestals, guide rail, elevating device, liquid indicator, pressure gauge, pressure regulator, etc.

Rotary wheel fully made of stainless steel SUS 304. Filling valves are made of SUS316L. Filling valves are reasonably structured with accurate filling. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

| Model | MIC-24-24-6 |

| Washing heads |

32pcs |

| Filling heads |

24pcs |

|

Capping heads |

8pcs |

|

Volume |

0.1-1.5L |

|

Production capacity |

3000-5000bottle/hr base on 1000ml |

|

Filling method |

Normal pressure |

|

Power |

2.5kw 380V/50HZ(According to

customer) |

|

Air pressure |

0.7Mpa |

|

Gas consumption |

0.8m³/min |

|

Water consumption for bottle washing |

1.5-2T/H |

|

Wash bottle water pressure |

0.2~0.25 Mpa |

|

Weight |

4500kg |

|

Dimension |

3000×1500×2500mm |

| Electrical configuration | |

|---|---|

| Touch screen | DELTA |

| Frequency converter | MITSUBISHI |

| PLC | MITSUBISHI |

| Contactor, breaker | DELIXI |

| Proximity switch | DELIXI |

| Photoelectric switch | DELIXI |

| Bearing | Harbin |

| Relay | OMRON |

| Barometer | AirTAC |

| Air cylinder | AirTAC |

| Solenoid valve | AirTAC |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine