Products

Glass Bottles, Plastic Bottles And Cans Can Be Filled

...

Zhangjiagang Micmachinery.co.,ltd

Zhangjiagang Micmachinery.co.,ltd is a professional enterprise which has machine design and sale department, providing turnkey project for different field business client since 1999 year. With over decades production and installation, we become ...

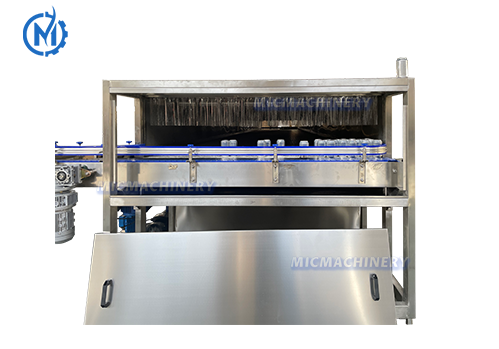

Packing Machine

MIC-20P Pastic Bottle Shrink Packing Machine (10-15bpm)

◆ Basic Configuration

● Siemens-Germany : PLC Control system.

● Touch screen: Siemens 1set.

● Taiwan Airtac pneumatic component 1set.

● Siemens frequency 2set.

● Stainless steel wing heating tube 12pcs.

● China-USA cooperation Teflon convey belt.

● South Korea Autonics photoelectricity switch, approach witch.

● Whole machine appearan...

MIC-10C Case Packing Machine (10 Cartons/m)

Title: Streamlining Packaging Processes: The Performance of Case Packing Machines

In modern manufacturing, the efficiency and accuracy of packaging processes are essential for meeting production goals and ensuring customer satisfaction. Case packing machines, including case packers and automated case packers, play a crucial role in optimizing these processes. Let's explore how these machin...

PET Bottle Blowing Machine

Semiautomatic bottle blow molding machine

Semiautomatic bottle blow molding machine can produce PET containers including the bottles for kinds of drink , soybean, vinegar, and pesticide (less than 10liters) according to the different bottle shape and diameter.

1. Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,...

Pallet Winding Machine

The machine motor, electric wire, chain device such as a dangerous all build.To ensure the safety of operating personnel.

New 360 arc column design, concise and easy appearance.

PLC programmable control, winding program is optional.

Optional multi-function man-machine interface touch screen display system, real-time display equipment running status.

German P + F photoelectric switch from dynam...

Can Depalletizer Machine

MIC XD-SS-1 Series Full Automatic Empty Can Depalletizer is mainly used for stacking various Aluminum Cans, Tin Cans, PET Cans,Glass bottle, etc.and sta

Features:

1.The low-position box takes up less space and has a large production capacity.

2.The whole machine is controlled by PLC, fully automatic operation.

3.Adapt to a variety of stack types and bottle types, easy to adjust.

...

Carbonated Drink Mixing Machine

The pre-cooled and pre-carbonized liquid flows through the inlet valve into the pot, in which, there is carbonic acid gas as well. The liquid flows out the groove and turns into a liquid curtain for better cooling and good carbonic acid gas absorption. Finally, the treated beverage liquid, powered by the carbonic acid gas pressure, flows into the filling machine.

Quality materials are used...

Pasteurization Machine Beer Tunnel Pasteurizer

Automatic Steam Chamber Glass Bottle Aluminum Can Juice Beer Sterilizer Machine Sterilization Tunnel

This pasteurizer is designed and manufactured for use in beer and other beverage filling production lines. It is a tunnel

pasteurizer which is a method of processing containers that have already been filled. The unprocessed product is poured into the container, the container is sealed, and...