- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

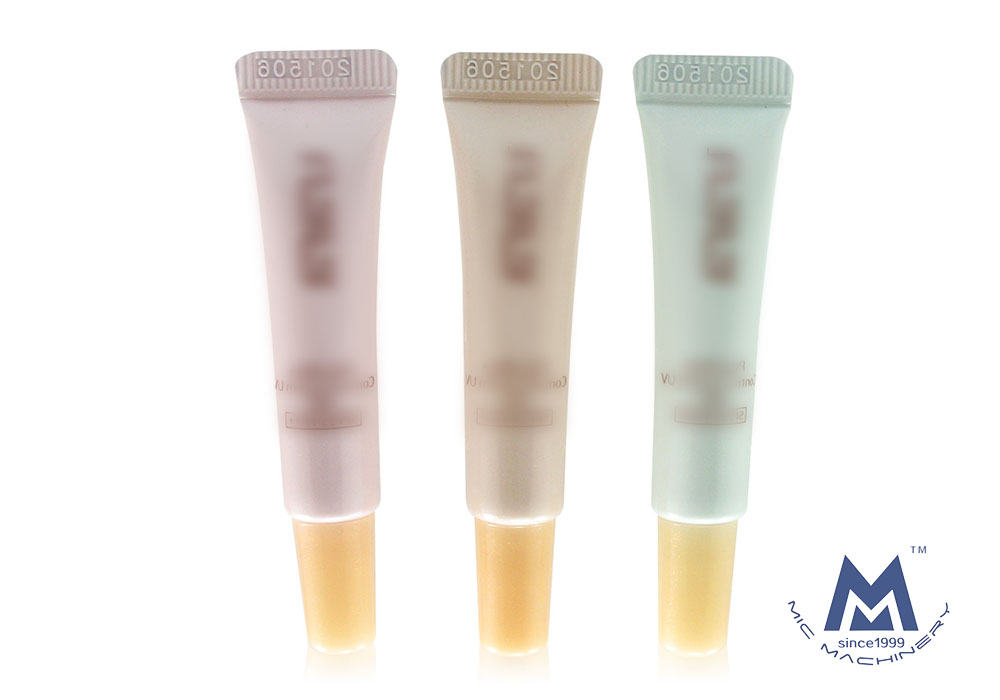

This machine is mainly used for Plastic & Laminated tube filling and sealing.

It has been widely used in the fields of Pharmacy, cosmetic, food and chemical etc.

This machine function is:

1. Automatic tube loading

2. Automatic benchmarking (Cursor positioning)

3. Automatic tube filling sealing & No tube no filling

4. Automatic heating sealing (Swiss hot gun heating)

5. Automatic printing the batch dates code

6. Automatic cut the over part with air blow after sealing then output finish product

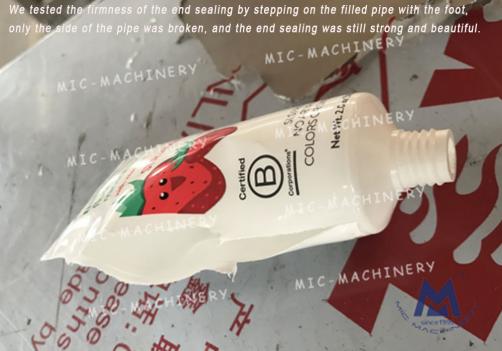

MIC-R60 tube filling machine applicable to the pharmaceutical, food, cosmetics, daily chemical industry, the aluminum pipe for filling and sealing.Also We tested the firmness of the end sealing by stepping on the filled pipe with the foot, only the side of the pipe was broken, and the end sealing was still strong and beautiful.Can all mushy, paste and viscous fluid and the material smooth accurately into the tube, and complete folding, sealing, batch number, production date.The machine adopts the touch screen and PLC control system in Taiwan, which realizes non-contact operation, intuitive and reliable operation.The machine has compact structure, automatic upper tube, and fully enclosed transmission.By the automatic control system to complete the supply pipe, washing pipe, the subject, filling, folding, sealing, coding, production process.By pneumatic method to complete the supply pipe, washing pipe, accurate and reliable action.Automatic calibration by using photoelectric sensor.Easy disassembly and easy adjustment.

-We offer our technician for oversea to install and adjust machine, do field installation guidance.

-We provide the full-lifetime warranty consult with one more two years free accessories support.

-24 hours online support, when you meet the problem we will provide video explain

About the advantages of fully automatic flexible tube machine

you can also check for:

|

Voltage |

110V/220V/380V |

|

Power |

1.1kw |

|

Filling Head |

Diving piston filling |

|

Air Pressure |

0.6-0.8Mpa |

|

Production Capacity |

60-85 tubes/min |

|

Filling Volume |

1-300ml |

|

Filling Error |

±0.5g |

|

Material |

SS304/316 |

|

Dimensions |

1950*800*1850mm |

|

Weight |

850KG |

| Parts | Brand |

|

Touch Screen |

Siemens |

|

Main Motor |

Tai Wan chen Bang |

|

PLC |

Siemens |

|

Stepping Motor |

East Japan |

|

Stepping Drive |

East Japan |

|

Sensor |

Germany Sick |

|

Approach Switch |

Germany Sick |

|

Intermediate Relay |

Schneider |

|

Electromagnetic Valve |

Germany SMC |

|

Encoder |

Omron |

|

Mixing Motor (Optional) |

JSCC |

|

Air Cylinder |

SMC |

|

Bearing |

FAGINA |

|

Button |

Schneider |

|

Air Switch |

Schneider |

|

Power Switch |

Schneider |

|

Temperature Control |

Schneider |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine