- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

1. Machinery structure more stable , adopt Germany FAG bearing , Precision more higher , use life more longer and low noise.

2. Sealing tube tail effect is better , one time forming, more beautiful and stable

3. Speed is more faster , structure is more reasonable , max speed can reach 80 tubes/min

4. Machine frame platform use Casting manufacturing, 30mm thick cast iron platform substrate, the pig iron structure is not easy to be deformed, the frame is heavy, the seismic performance is better, and the service life is longer.

5. Configuration more better, Germany Siemens PLC , CPG motor and so on

6. Motor use TaiWan CPG motor, lower noise

7. The sealing parts are made of German imported DC53 material, and are vacuum-fired process for wear resistance and long service life.

Instruction and features:

1. With functions of count and machine stop by fixed amount

2. Failure warning function, no tube warning function, overloading warning function.

3. No tube no filling

4. Automatic lot No. print, automatic tube out

5. Automatic tube supply, automatic color code fixing.

6. Automatic filling, and with the function of end cut-off for viscidity materials.

7. Drive part is closed on the underside of the platform, safe and no pollution.

8. Filling & Sealing part is put in the semi-closed & no static electricity sight cover, which is above the platform, so it is easy to observe and operate.

9. Machine surface is smooth, even, no blind corner, nontoxic, odorless, no pollution, and is easy to clean and maintain.

10. The machine, with compact construction is easy to operate so it is applicable in such fields as medicine, foodstuffs, daily chemical articles etc.

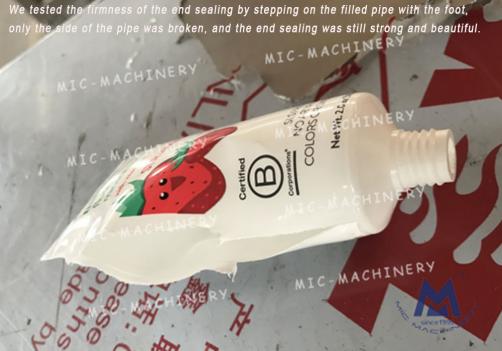

*In the end sealing aspect,we tested the firmness of the end sealing by stepping on the filled pipe with the foot, only the side of the pipe was broken, and the end sealing was still strong and beautiful.

About the advantages of fully automatic flexible tube machine

you can also check for:

|

Voltage |

110V/220V/380V optional |

|

Main Motor Power |

4.5kw |

|

Air Source |

0.6-0.8 Mpa |

|

Air Consumption |

0.6 m^3/min |

|

Capacity |

30-60 tubes/min |

|

Filling Accuracy |

+/-1% |

|

Size |

1950*800*1850mm |

|

Weight |

850kg |

|

Parts |

Brand |

|

touch Screen |

Siemens / Schneider (Optional) |

|

Main Motor |

Tai Wan CBG |

|

PLC |

Siemens / Schneider(Optional) |

|

Stepping Motor |

East Japan |

|

Stepping Drive |

East Japan |

|

Sensor |

Germany Sick |

|

Approach Switch |

Germany Sick |

|

Intermediate Relay |

Schneider |

|

electromagnetic Valve |

Germany SMC |

|

Encoder |

Omron |

|

Mixing Motor (Optional) |

JSCC |

|

Air Cylinder |

SMC |

|

Bearing |

FAGINA |

|

Button |

Schneider |

|

Air Switch |

Schneider |

|

Power Switch |

Schneider |

|

Temperature Control |

Schneide |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine