- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

Introduce of main steps:

Step 1: the tubes will be conveyed into the molds on the plate by tube loader tunnel automatically(16 points)

Step 2: Tubes point fix location by the device(color sensor optional)

Step 3: Starting filling when the tube is sensed by the light

Step 4: 4 folds sealing and output finished products

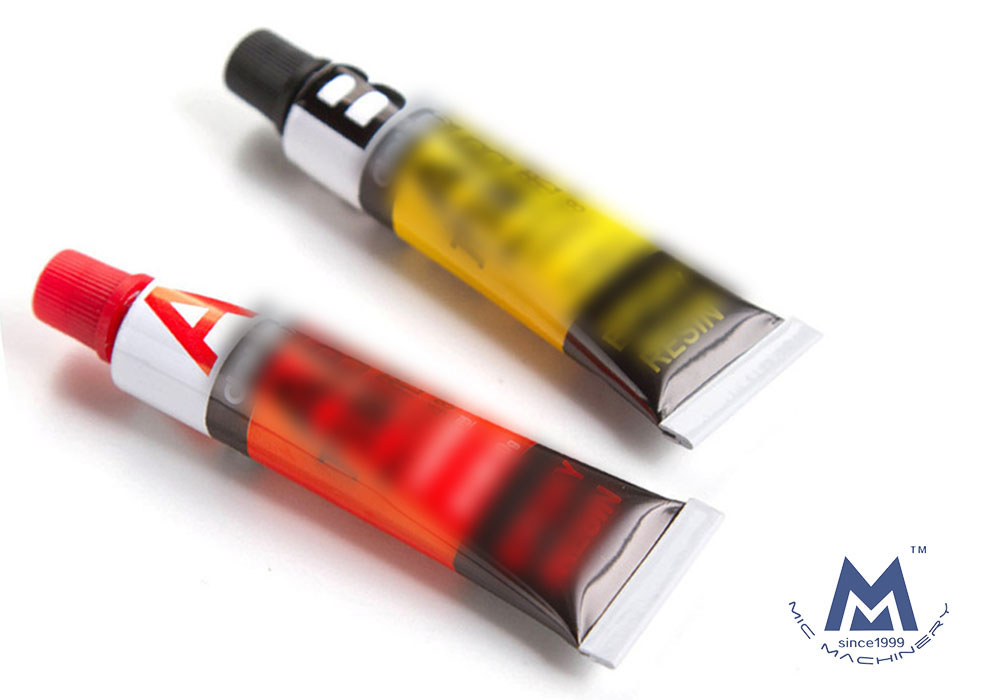

Automatic aluminum tube filling sealing machine with one filling head has multiple purpose, it is ideal equipment aluminum tube. A automatic aluminum tube filling and sealing machine is widely used for metal hose filling and sealing. Putting the tube into a rotary indexing table, orients the tube then fills and seals by folding for aluminum metal tubes. This L60 cosmetic filling and sealing machine has 16 positions in total. It is suitable for food products, chemical products, greases. gels. glues, epoxy glue, skin cream and so on.

Automatic aluminum tube filling sealing machine can be applicable to different volume and diameter metal tube filling and sealing, it can fill the material such as paste , gel ,glue , cream ,paint ,ointment.

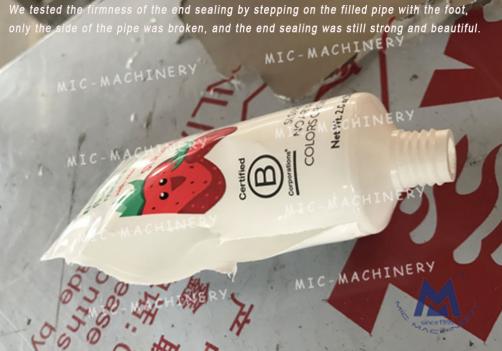

About the seal::We tested the firmness of the end sealing by stepping on the filled pipe with the foot, only the side of the pipe was broken, and the end sealing was still strong and beautiful.

1. Hopper: where the filling material are loaded

2. Control panel: To control the machine

3. Electric Box: Contain all the motive parts, such as motor, transducer, electric box. PLC etc...

4. Filling Head: Filling the material

5. Tube Loader: where are the tubes are loaded in the loader. they will be conveyed automatically to the working desk by tunnel

6. Folding Head: Folding the bottom of tube

7. Tube Orientation

Thank you for the reading this article,

you can also check for:

|

Weight |

1200 Kg |

|

Dimension |

1900*1400*2000mm |

|

Power |

220V/50Hz |

|

Motor |

2.2 Kw |

|

Filling Quantity |

3-20ml,15-75ml, 75-250ml |

|

Capacity |

50-60 tpm |

|

Name |

Brand |

|

Framework |

SUS 304 Stainless steel |

|

Junction Box |

CZ Explosion-proof |

|

Button |

CZ Explosion-proof |

|

Main Servo Motor |

Siemens (Explosion-proof One Zone) |

|

PLC |

Siemens |

|

Stepping Motor |

Siemens (Explosion-proof One Zone) |

|

Stepping Drive |

Siemens |

|

Color Mark Sensor |

P+F, Germany |

|

Approch Switch |

P+F, Germany |

|

Media Relay |

Siemens |

|

Magnetic Valve |

SMC, Japan |

|

Divider |

Yddex, Shangdong |

|

Pneumatic Elements |

SMC, Japan |

|

Servo Pump for Filling |

Micmachinery |

|

Bearings |

FAG, Germany |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine