- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

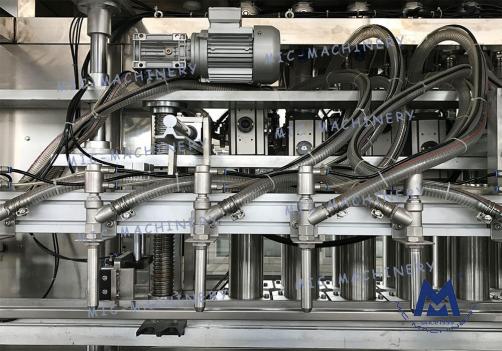

The machine adopts PLC control, according to the filling bottle, fixed discharging mouth, the rest all operation can be finished on a touch screen. In addition to have common automatic servo piston filling machine advantages, also the widened the range of filling material. Such as filling material contains particles, long strips of solid content, also can be a very effective filling.

The installation can be provided by the we Company. It must be after shipment and machine has arrived and factory must be ready equipped with all necessary requirements before booking installation with we Company. Our engineers will come to the site for the complete and final installation. During the installation session, a one day training course will be provided to the customer to the customer for operation and maintenance procedure.

|

Filling head |

16 heads |

|

Filling type |

Gravity |

|

Filling capacity |

100ml-5000ml |

|

Production speed |

It can achieve 3200 bottles per hour |

|

Power supply |

220V/380V Single-phase |

|

Power |

2Kw |

|

Suitable bottle size |

Ф40mm-Ф100mm |

|

The measurement error |

≤±0.5% |

|

Working pressure |

0.55Mpa-0.7Mpa |

|

Dimension |

2440mm × 1240mm × 2350mm |

|

Gas consumption |

0.9m3/min |

|

Machine weight |

700 kg |

|

Touch screen |

Canada Xinje color screen |

|

PLC programmable |

Schneider France |

|

Solenoid valve |

Taiwan Yadeke |

|

Photoelectric system |

Japan stately |

|

Differential switch |

Holland |

|

Source |

Taiwan Yadeke |

|

Button and other low-voltage electrical appliances

|

France Schneider |

|

Reducer |

Taiwan VGM |

|

Alarm |

Real-time fault alarm and emergency stop automatically |

|

Material |

Use 316 stainless steel in contact with the material, the other main parts are made of 304 stainless steel

|

|

Sealing ring |

Use of carbon PTFE fiber materials, anti-corrosion,wear resistance, good sealing |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine