- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

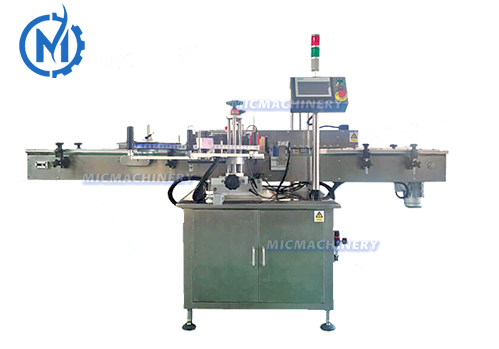

Special for box corner labeling, on the upper plane and side plane corner labeling, play an anti-disassembly role.It is mainly used in the double side labeling of anti-disassembling labels of CARDS, electronic products, mask boxes and medicine boxes.

Automatic corner labeling machine can be combined with plane labeling machine to form continuous labeling.

Ii. Scope of application

1. Applicable label: adhesive label, non-drying film, electronic supervision code, bar code, etc.2. Applicable products: various paper boxes, such as poker boxes, mobile phone boxes, etc.

3. Application: widely used in printing, food, daily chemical, electronics, medicine and other industries.

4. Application examples: anti-detachable labeling of nestle box, anti-detachable labeling of card box, anti-detachable labeling of network card box, mask box, etc.

Three, the work process

Core working principle: the sensor detects the passing of the product, and sends back the signal to the labeling control system. In the appropriate position, the control system controls the motor to send out the label and attach it to the position of the product to be labeled.Operation process: product (receiving line) -- > product transportation -- > product detection -- > bilateral labeling -- > brush labeling -- > collection of pasted products (flowing into the next assembly line).

Four, function characteristic

1, dedicated to box corner labeling, to achieve the box upper plane and side plane corner labeling, play an anti-dismantling role;2. High speed, the speed of labeling the corner of playing CARDS reaches 180 boxes/min, greatly improving the production efficiency;

3. Label is firm and does not fall off.On the upper plane of the label, the roller rolls the overlaying label and sticks it firmly; on the side plane, the brush strokes and presses it firmly;

4. The labeling is beautiful, the top pressing mechanism is set, the box has high conveying stability, and the labeling and overlaying effect is good;

5. Intelligent control, automatic photoelectric tracking, with the functions of no label, no label automatic correction and automatic label detection, to prevent label leakage and label waste;

6. High stability, advanced electronic control system composed of Siemens PLC+ Siemens touch screen + keenz needle electric eye + German labor easy test label electric eye, supporting the equipment to operate 7×24 hours;

|

Voltage specification |

AC220V 50/60HZ |

|

Consumed power |

1200W |

|

Labeling speed |

40-70 vials/min (adjustable speed, depending on object size and label length) |

|

Labeling accuracy |

+1mm (depending on product characteristics, hardness and roundness) |

|

Conveyor speed |

50-80 boxes per minute |

|

Scope of object |

Length 20-300mm width 50-200mm height 25-300mm |

|

label specification |

Width 20mm ~ ~ 130mm length 15 ~ ~ 100mm (special specifications can be customized) |

|

Paper roll diameter |

Φ paper roll diameter: 76 mm Φ 320 (maximum) |

|

Heavy volume |

200KG |

|

Packing size |

1800X900X1300mm |

|

The following is the standard model technical parameters, other special requirements and functions, can be customized |

|

|

Part name |

nameplate |

|

Label step motor |

joint venture |

|

Label the motor drive |

|

|

Conveyor belt motor |

Germany |

|

Conveyor belt motor gear box |

|

|

Correction of the motor |

|

|

Calibration of motor gear box |

|

|

Pressure on the motor |

|

|

Up pressure motor gear box |

|

|

Labeling photoelectric |

Japan |

|

Label detection photoelectric |

Germany |

|

Programmable controller |

Siemens |

|

Man-machine interface |

Siemens |

|

Conveyor belt |

Shanghai |

|

Synchronous toothed belt |

Japan |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine