- E-mail: sales8@micmachinery.com

- Mobile: 0086-13771181029

- Whatsapp: 0086-13771181029

- Wechat: 0086-13771181029

- Shipment: exporting country

- Customer reviews: click on

This filling capping machine is suitable for:

A variety of small doses of liquid filling & capping such as oil, injection. Widely used in food, pharmaceutical, chemical industries and scientific research.

This machine is one of the traditional filling and capping equipment, advanced design, reasonable structure, can automatically complete filling and capping process, is suitable for the liquid ,such like perfume, syrup, tincture, alcohol,wine a variety of materials such as,and other functions. Can be used stand-alone, and also can be used for filling line. This machine completely accords with the new GMP requirements and EU certification.

Characteristic

The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

It has intuitive and convenient operation, measuring accurate, positioning precision

Three knife centrifugal sealing, to ensure the sealing strong and beautiful

Fully in accordance with the GMP standard production

Main Features Of MIC-L40 automatic e-liquid bottle filling capping and labeling machine

1. Microcomputer setting, high filling accuracy

2. The main engine is equipped with stepless frequency speed control.

3. Automatic production capacity quantitative control.

4. With all kinds of fault alerting, for low pressure, no filling, no inner cap etc.

5. The machine can stop automatically in case of no filling, no inner cap etc.

Thank you for the reading this article,

you can also check for:

|

Filling volume |

5-50ml |

|

Loading error |

≤ ±1% |

|

Rotation (rolling) Cover pass rate |

≥99% |

| Production capacity |

30-50BPM |

|

60-90BPM |

|

|

Power supply |

380V/50Hz |

|

Power |

2.0 kw |

|

Weight |

600 kg |

|

Dimension |

2000*1000*1500mm |

|

Name |

Brand |

|

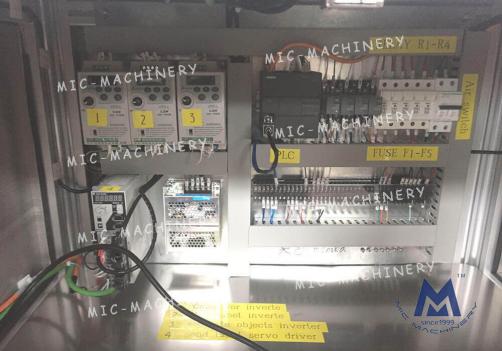

Press-button |

Schneider |

|

Magnetic Contactor |

Schneider |

|

Relay |

Omron |

|

Frequency Transformer |

Mitsubishi |

|

Motor |

JSCC made in Germany |

|

Air Cylinder |

Airtac |

|

Solenoid Valve |

Airtac |

|

Speed Reducer |

Made in Taiwan |

|

Bearing |

NSK |

|

PLC |

Mitsubishi |

|

Touch Screen |

Mitsubishi |

|

Fibre-optical |

Autonics |

|

Switching Mode Power Supply |

NWELL |

|

Step Motor |

SNAYO made in Japan |

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Beer Filling Machine

- Juice Filling Machine

- Soda Filling Machine

- Drink Filling Machine

- Carbonated Soft Drink Filling Machine

- Beverage Filling Machine

- Labeling Machine

- Packing Machine

-

Beer Beverage Filling Machine

- Can filling machine

- Glass bottle filling machine

- Pet bottle filling machine

- Beer Filling Machine

- Beer Can Filling Machine

- Beer Bottle Filling Machine

- Semi Automatic Beer Filling Machine

- Soda Filling Machine

- Soda Bottling Machine

- Juice Filling Machine

- Juice Can Filling Machine

- Beverage Filling Machine

- Carbonated Drink Filling Machine

- Edible Oil Filling Machine

- Can filling machine